Method for manufacturing nitride gradient energy gap resonance tunneling ohmic contact

A technology of ohmic contact and resonant tunneling, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of increasing ohmic contact resistance and depleting two-dimensional electrons, so as to reduce contact resistance and increase tunneling Through the current, improve the effect of tunneling current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

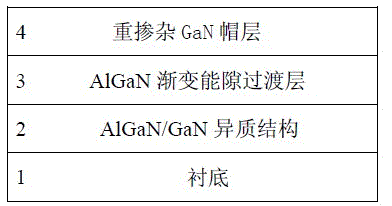

Embodiment 1

[0021] Consider the most commonly used by Al 0.3 Ga 0.7 Heterostructure 2 composed of N barrier layer and GaN channel layer. The simulation calculation shows that the electron gas density is 9.27*10 12 cm -2 . After covering the AlGaN gradient transition layer 3 and the heavily doped GaN cap layer 4 on the heterostructure, self-consistently solve the Schrödinger equation and Poisson equation, and optimize the design by doping concentration 3*10 19 cm -3 The 8nm GaN cap layer 4 and the Al composition ratio increase linearly from 0 to 0.3, and the doping concentration is 2*10 19 cm -3 and the graded-gap resonant tunneling ohmic contact formed by the graded-gap transition layer 3 with a thickness of 15 nm. The simulation calculation shows that the ground state energy level in the channel well is -0.84eV, and the quantum confinement energy level in the middle well is -0.79eV. The energy level difference is only 0.05eV, and the three-dimensional electrons on the metal elect...

Embodiment 2

[0023] In the research of millimeter-wave high-frequency devices, in order to improve the control of the gate electrode on the channel conductance and weaken the short-channel effect, a thin barrier with a high Al composition ratio must be used. Considered by 8nmAl 0.5 Ga 0.5 Heterostructure 2 composed of N barrier layer and GaN channel layer. The simulation calculation shows that the electron gas density is 1.298*10 13 cm -2 . After covering the AlGaN gradient transition layer 3 and the heavily doped GaN cap layer 4 on the heterostructure, self-consistently solve the Schrödinger equation and Poisson equation, and optimize the design by doping concentration 3*10 19 cm -3 The 8nm GaN cap layer 4 and the Al composition ratio increase linearly from 0 to 0.5, and the doping concentration is 2.2*10 19 cm -3The graded-gap resonant tunneling ohmic contact formed by the graded-gap transition layer 3 with a thickness of 20 nm. The simulation calculation shows that the ground st...

Embodiment 3

[0025] In order to strengthen the quantum confinement of the channel well and suppress the alloy scattering in the AlGaN alloy layer, many authors have studied the AlN / GaN superlattice barrier to replace the AlGaN alloy layer barrier. Consider a heterostructure 2 consisting of five sets of 1.8nmGaN / 0.8nmAlN heterojunction layers consisting of a superlattice barrier layer and a GaN channel layer. The simulation calculation shows that the electron gas density is 1.29*10 13 cm -2 . After covering the AlGaN gradient transition layer 3 and the heavily doped GaN cap layer 4 on the heterostructure, self-consistently solve the Schrödinger equation and Poisson equation, and optimize the design by doping concentration 3*10 19 cm -3 The ratio of the 8nm GaN cap layer 4 to Al increases linearly from 0 to 0.4, and the doping concentration is 2*10 19 cm -3 The graded-gap resonant tunneling ohmic contact formed by the graded-gap transition layer 3 with a thickness of 20 nm. The simulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com