Absolute type grating scale absolute position information correction and read circuit

An absolute position and correction circuit technology, applied in the direction of the instrument, can solve the problems of non-uniform distribution of light sources, complex processing circuits, incomplete matching of photodetectors, large influence on output signal swing and signal-to-noise ratio, and achieve circuit parameters. Simple configuration and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

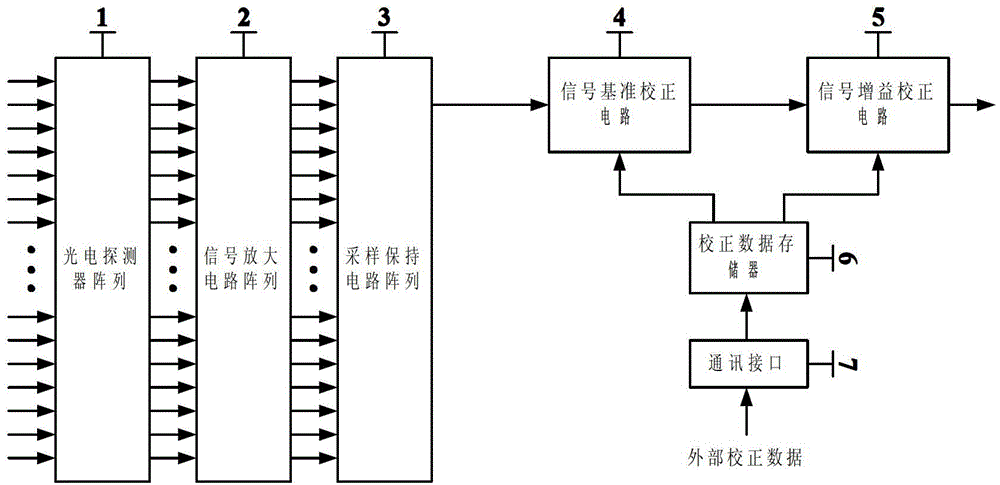

[0015] like figure 1 As shown, a correction and reading circuit for the absolute position information of an absolute grating ruler, the circuit includes: photodetector array 1, signal amplification circuit array 2, sample and hold circuit array 3, signal reference correction circuit 4, signal gain correction Circuit 5 and reading correction data memory 6; each photodetector unit in the photodetector array 1 receives an optical signal representing absolute position information, and the photodetector units are arranged in parallel with each other in a row, with a certain period and a duty ratio, The size of the photodetector unit is set to a specific value according to factors such as the photoelectric response efficiency, the light intensity used, the size of the sample and hold circuit unit, and the exposure time, and the number of photodetect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com