Silica aerogel microsphere composite thermal insulation coating

A technology of silica and thermal insulation coatings, applied in the direction of epoxy resin coatings, coatings, etc., can solve the problems of reducing the internal gas phase heat conduction and convective heat transfer of airgel, and the decrease of thermal conductivity of silica airgel, etc. Achieve the effect of improved heat insulation performance, low density and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

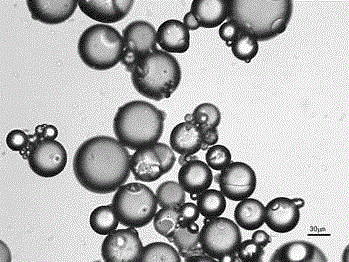

[0032] Mix tetraethyl orthosilicate (TEOS) with absolute ethanol (Ethanol) and deionized water and stir evenly, then add nitric acid to mix and stir. The molar ratio of raw materials used is TEOS: Ethanol: deionized water: nitric acid = 1:0 ~15: 1~10: 0.0005~0.08 Then put the mixed solution in a water bath and keep it warm for more than 1 hour to obtain silica sol; use an atomizer to spray the silica sol into the oil phase, the diameter of the nozzle of the atomizer is 0.1mm, ensure that the oil phase has a rotational speed of 500r / min~1000r / min during the atomization process. The oil phase selected for atomization is to disperse the wet gel microspheres evenly, and ensure that the volume of the sol in the oil phase does not exceed 1 / 5 of the volume of the oil phase during atomization. After the atomization is completed, ammonia water is added to the mixed solution. The amount of ammonia water is based on the fact that the mixed solution begins to produce gel, and aged at room...

example 2

[0036] Mix tetraethyl orthosilicate (TEOS) with absolute ethanol (Ethanol) and deionized water and stir evenly, then add nitric acid to mix and stir. The molar ratio of raw materials used is TEOS: Ethanol: deionized water: nitric acid = 1:0 ~15: 1~10: 0.0005~0.08 Then put the mixed solution in a water bath and keep it warm for more than 1 hour to obtain a silica sol; use an atomizer to spray the silica sol into the oil phase, and use A nozzle with a diameter of 0.1mm and a nozzle with a diameter of 0.3mm are atomized, and the oil phase is guaranteed to have a rotational speed of 500r / min to 1000r / min during the atomization process. The oil phase selected for atomization is to disperse the wet gel microspheres evenly, and ensure that the volume of the sol in the oil phase does not exceed 1 / 5 of the volume of the oil phase during atomization. After the atomization is completed, ammonia water is added to the mixed solution. The amount of ammonia water is based on the fact that th...

example 3

[0039] Mix 208g of tetraethyl orthosilicate (TEOS) with 322g of absolute ethanol (Ethanol), 72g of deionized water and stir evenly, then add 1ml of 2w% nitric acid and mix and stir, then put the mixed solution in a water bath and keep it warm for more than 1h. Obtain the silica sol; spray the silica sol into the oil phase with an atomizer, the diameter of the atomizer nozzle is 0.1 mm, and ensure that the oil phase has a rotational speed of 500r / min-1000r / min during the atomization process. The oil phase selected for atomization is to disperse the wet gel microspheres evenly, and ensure that the volume of the sol in the oil phase does not exceed 1 / 5 of the volume of the oil phase during atomization. After the atomization is completed, ammonia water is added to the mixed solution. The amount of ammonia water is based on the fact that the mixed solution begins to produce gel, and aged at room temperature for two days to obtain silica wet gel microspheres. Filter the silica w...

PUM

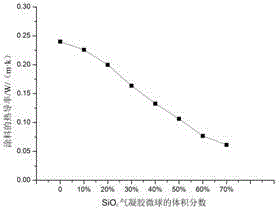

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com