Support controller for electrohydraulic control system

An electro-hydraulic control system and bracket controller technology, which is applied in mine roof brackets, mining equipment, earthwork drilling, etc., can solve the problem of slow communication speed of single-line CAN bus, limitation of the maximum number of nodes of CAN bus, and influence on the normal operation of control units, etc. problems, to achieve the effect of meeting the requirements of automatic control functions, enhancing anti-interference ability, and improving resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

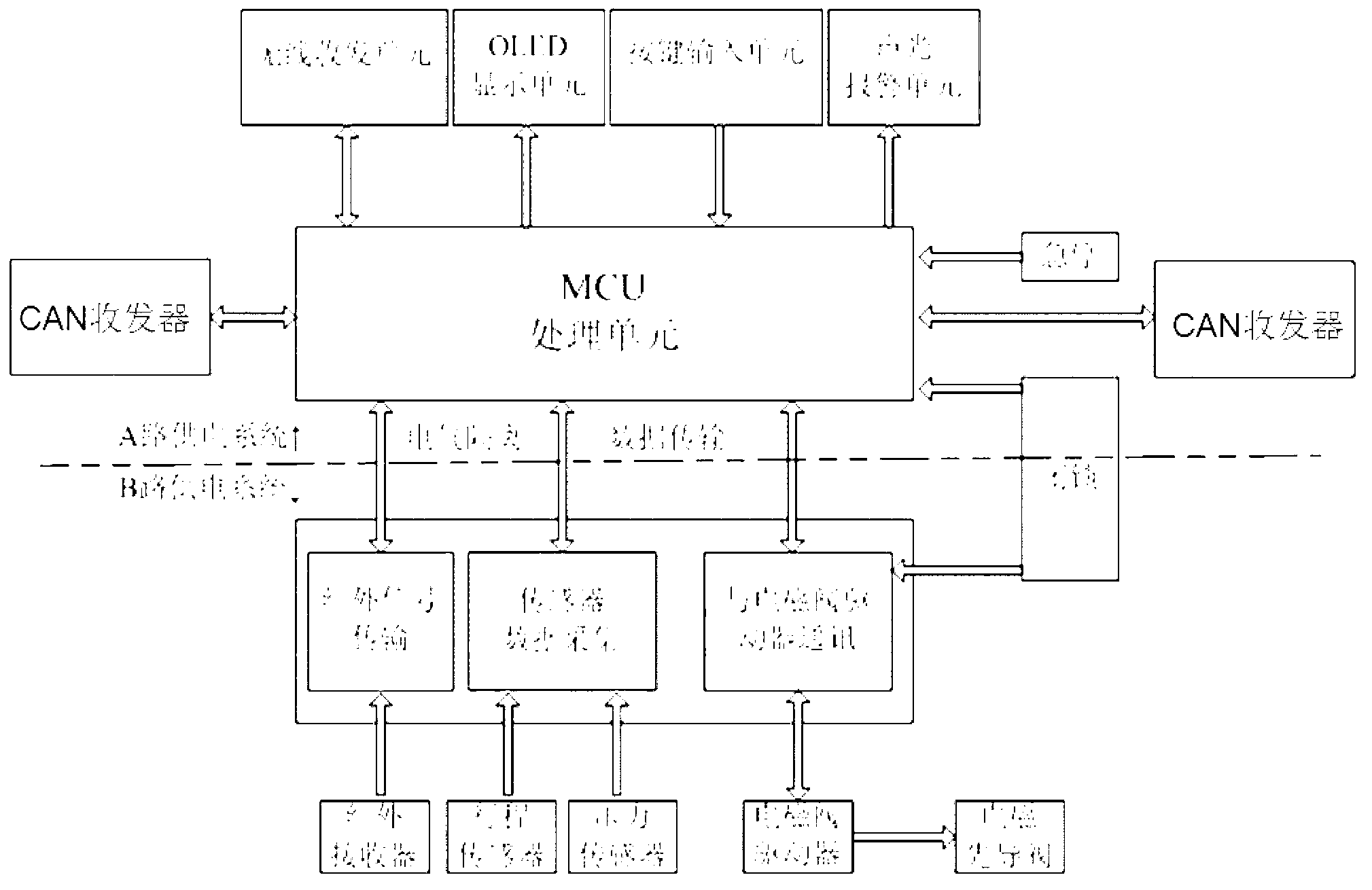

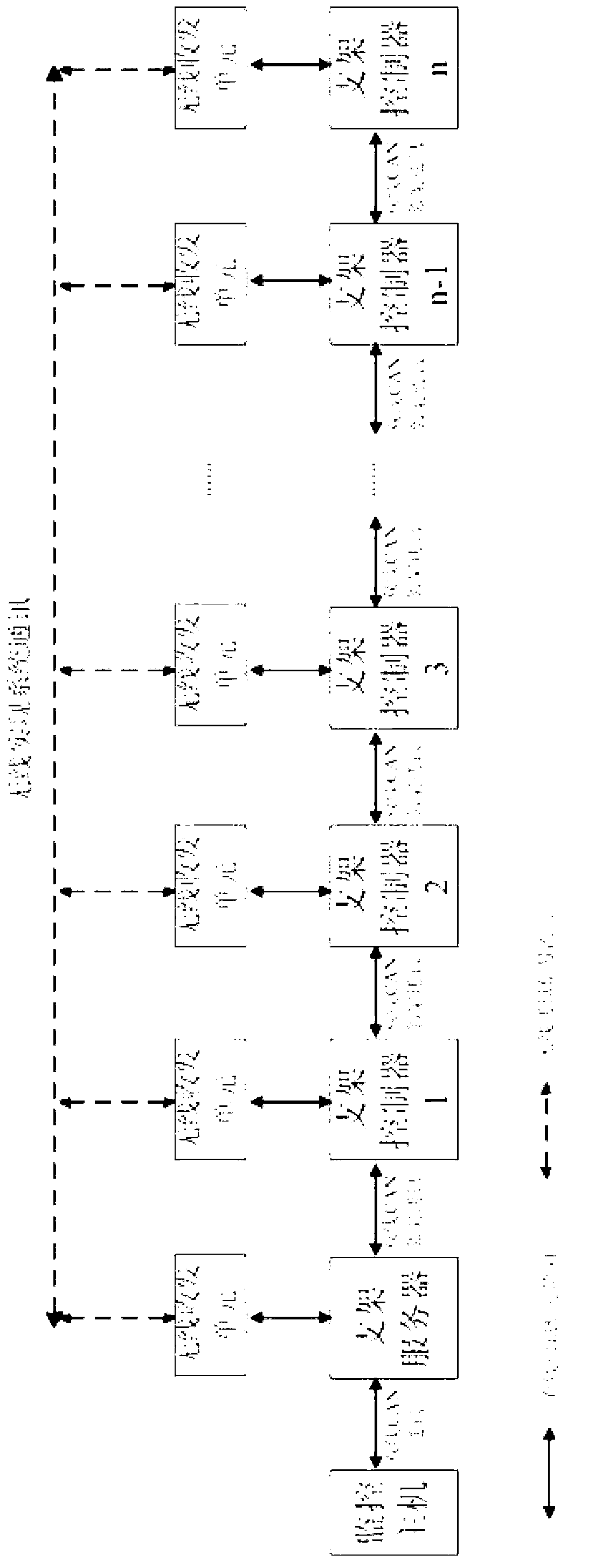

[0020] A bracket controller for electro-hydraulic control systems such as figure 1 As shown, it includes MCU processing unit, wireless transceiver unit, human-computer interaction unit, two CAN transceivers, data acquisition unit, solenoid valve driver, emergency stop locking unit and two-way power supply system. The MCU processing unit is respectively connected with the wireless transceiver unit, two CAN transceivers, the human-computer interaction unit and the emergency stop locking unit. The bracket controller realizes the mutual communication function of adjacent bracket controllers through two CAN transceivers. The wireless transceiver unit Use ZigBee or WiFi module to realize system data transmission function. The MCU processing unit is respectively connected with the wireless transceiver unit, the infrared receiver and the solenoid valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com