Acrylate rubber modified silicone rubber oil-resistant material and preparation method thereof

An acrylate and rubber modification technology, applied in the field of modified silicone rubber, can solve the problems of complex production process and high price and cost, and achieve the effects of overcoming uneven dispersion, low production cost and improving oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

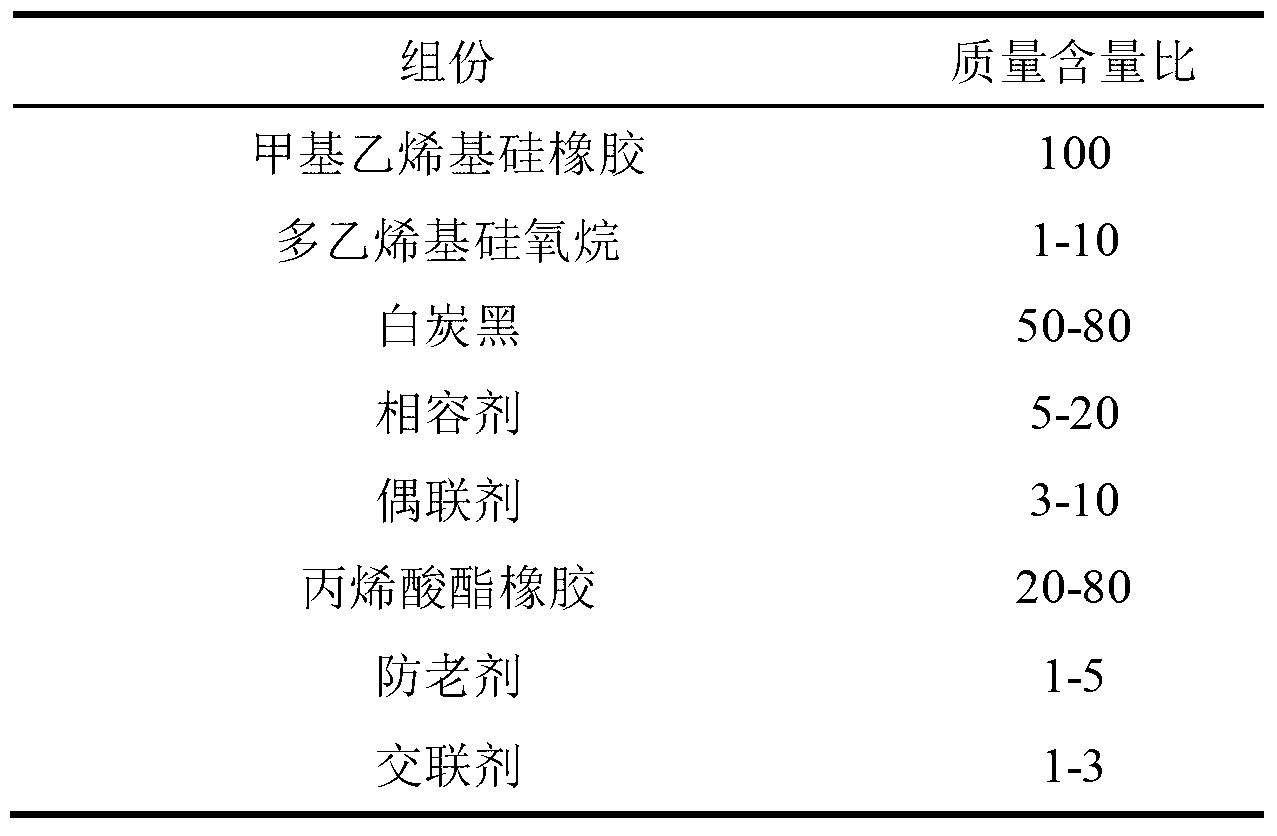

[0022] In the present embodiment, the raw materials are prepared according to the following formula:

[0023]

[0024] In this embodiment, the acrylate rubber modified silicone rubber oil-resistant material is manufactured through the following steps:

[0025] a. Knead 100 parts of methyl vinyl silicone rubber raw rubber and 5 parts of polyvinyl siloxane in a kneader by mass parts for 2 minutes;

[0026] b. Add 50 parts of precipitated silica and 3 parts of coupling agent KH570 in 3 times according to parts by mass, and fully knead for 10 minutes after each addition to obtain a silicone rubber compound with better performance;

[0027] c. Heat up the temperature of the silicone rubber compound to 120°C, add 5 parts of compatibilizer, 20 parts of acrylate rubber and 1.5 parts of anti-aging agent in parts by mass, knead in vacuum for 15 minutes, cool down to 80°C with cooling water, and then add 1.5 parts Cross-linking agent dicumyl peroxide and 0.5 parts of 2,5-dimethyl-2,5...

Embodiment 2

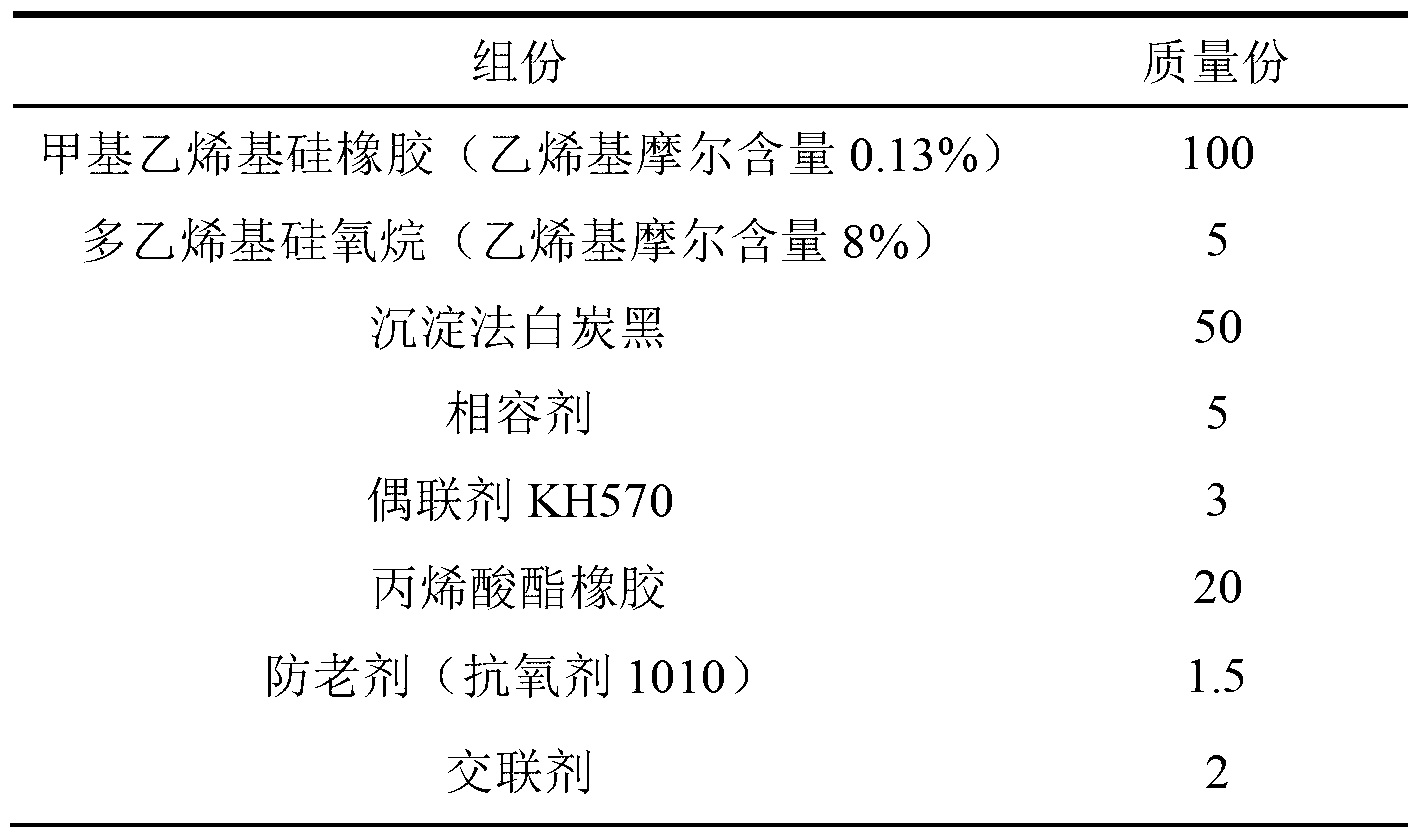

[0030] In the present embodiment, the raw materials are prepared according to the following formula:

[0031]

[0032] In this embodiment, the acrylate rubber modified silicone rubber oil-resistant material is manufactured through the following steps:

[0033] a. Knead 100 parts of methyl vinyl silicone rubber raw rubber and 8 parts of polyvinyl siloxane in a kneader by mass parts for 3 minutes;

[0034] b. Add 60 parts of precipitated white carbon black and 5 parts of coupling agent KH560 in 4 times according to parts by mass, and fully knead for 15 minutes after each addition to obtain a silicone rubber compound with better performance;

[0035] c. Heat up the temperature of the silicone rubber compound to 130°C, add 15 parts of compatibilizer, 60 parts of acrylate rubber and 3 parts of anti-aging agent in parts by mass, knead in vacuum for 25 minutes, cool down to 80°C with cooling water, add 1.8 parts of Combine dicumyl peroxide and 0.6 parts of 2,5-dimethyl-2,5-bis(te...

Embodiment 3

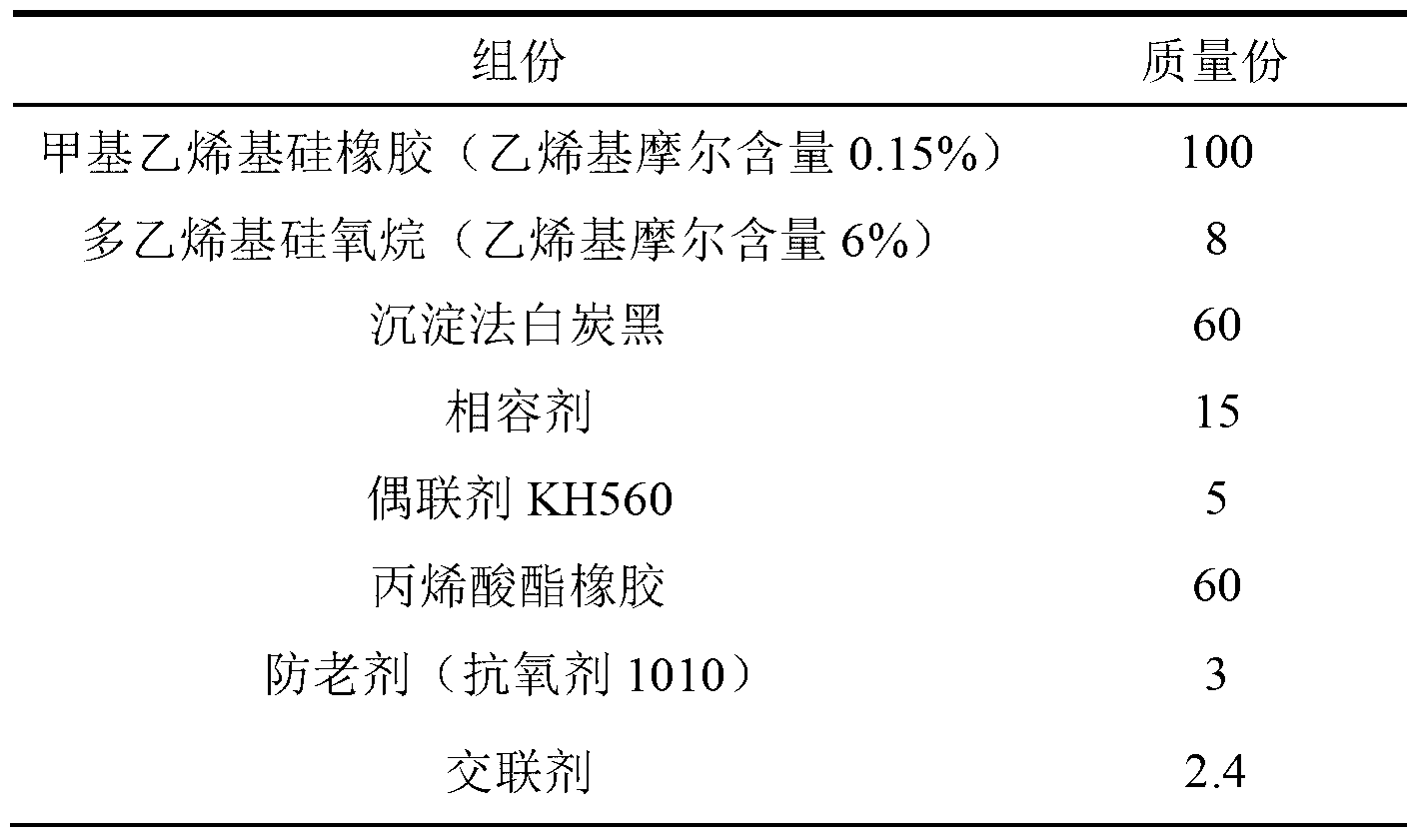

[0038] In the present embodiment, the raw materials are prepared according to the following formula:

[0039]

[0040] In this embodiment, the acrylate rubber modified silicone rubber oil-resistant material is manufactured through the following steps:

[0041] a. Knead 100 parts of methyl vinyl silicone rubber raw rubber with 8 parts of polyvinyl siloxane in a kneader for 3 minutes in parts by mass;

[0042] b. Add 60 parts of fumed white carbon black and 5 parts of coupling agent KH570 in 4 times in parts by mass, and fully knead for 15 minutes after each addition to obtain a silicone rubber compound with better performance;

[0043] c. Heat up the temperature of the silicone rubber compound to 140°C, add 60 parts of acrylate rubber and 3 parts of anti-aging agent in parts by mass, knead in vacuum for 30 minutes, cool down to 80°C with cooling water, add 1.8 parts of crosslinking agent diisoperoxide Propylbenzene and 0.6 parts of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com