Modified ternary copolymer, preparation method and applications thereof

An acrylate terpolymer and copolymer technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as low apparent viscosity, low anti-oxidation performance, and polymer chain degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

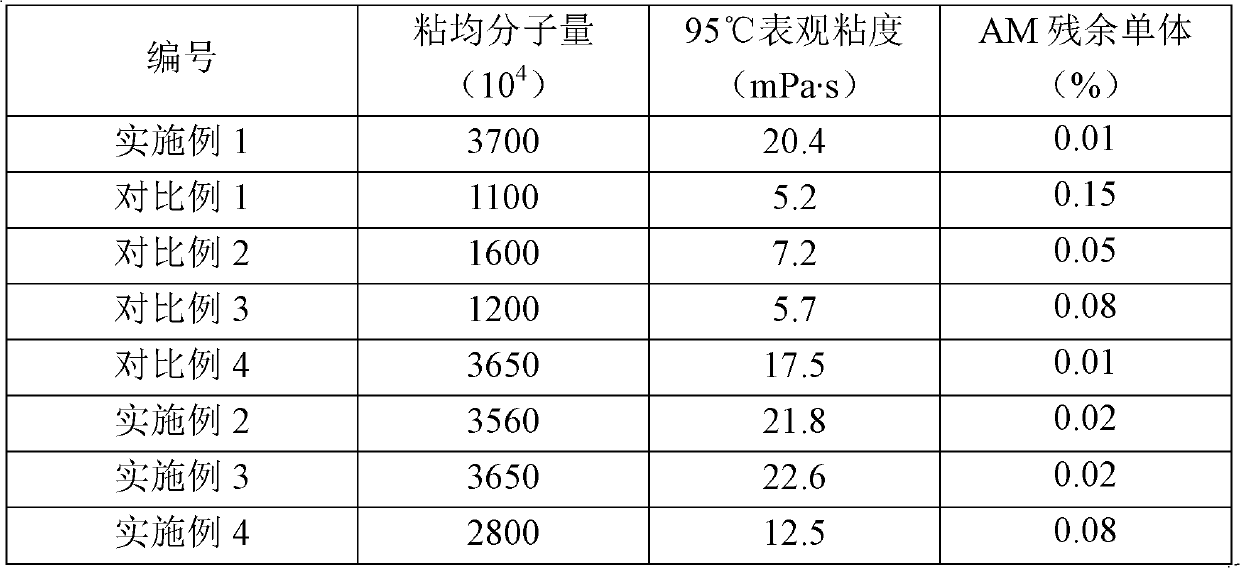

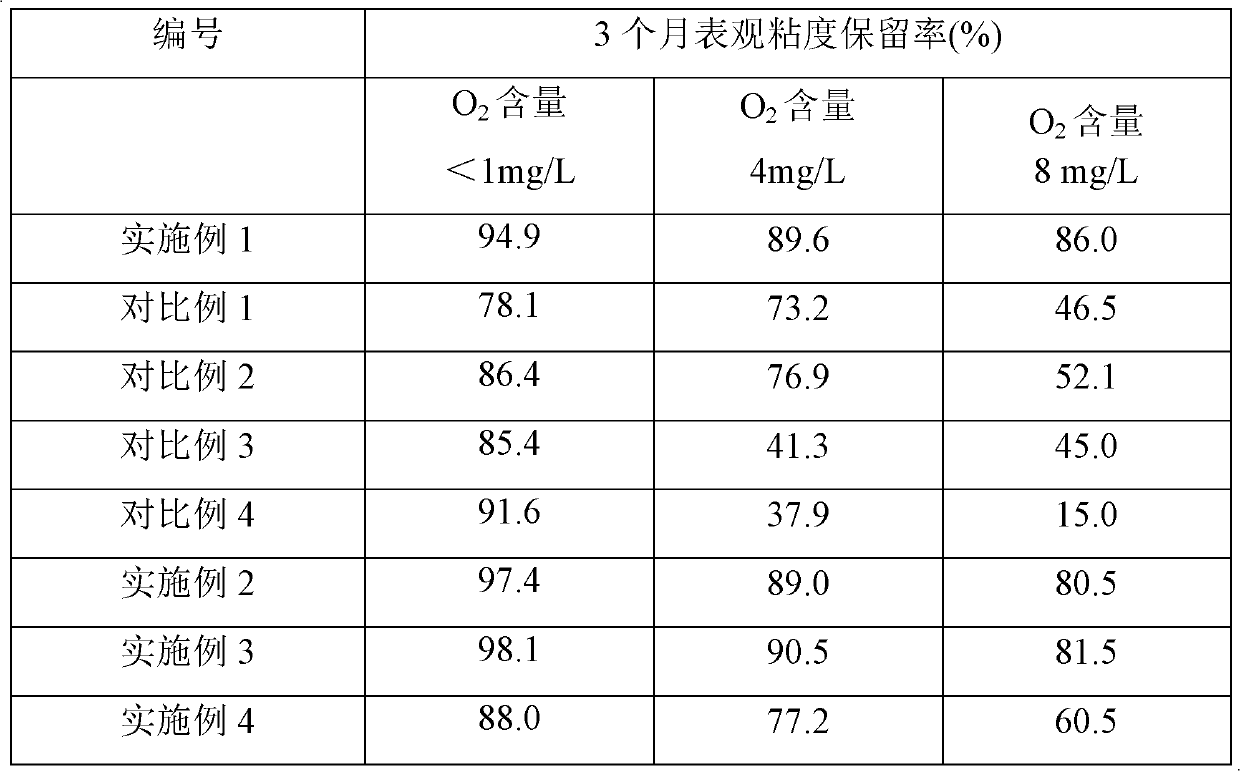

Examples

preparation example Construction

[0017] According to the preparation method of modified acrylamide / 2-acrylamido-2-methylpropanesulfonate / acrylate terpolymer of the present invention, the method may further comprise the steps:

[0018] (1) Purifying the crude product of 2-acrylamido-2-methylpropanesulfonic acid to a content of impurity 2-methyl-2-propene-1-sulfonic acid≤100ppm;

[0019] (2) Prepare an aqueous monomer solution of acrylamide and purified 2-acrylamido-2-methylpropanesulfonic acid, adjust the pH to 5-10 with an inorganic basic compound, and obtain acrylamide / 2-acrylamido-2 - methyl propane sulfonate monomer aqueous solution;

[0020] (3) Under the conditions of aqueous solution polymerization, under the protection of an inert gas, the initiator system is contacted with the above-mentioned acrylamide / 2-acrylamido-2-methylpropanesulfonate monomer aqueous solution, so that the acrylamide / 2-propene Amido-2-methylpropanesulfonate is polymerized to obtain acrylamide / 2-acrylamide-2-methylpropanesulfonate ...

Embodiment 1

[0062] This example is used to illustrate the modified terpolymer and its preparation method according to the present invention.

[0063] (1) Purification of 2-acrylamido-2-methylpropanesulfonic acid

[0064] at 1m 3 Add 600 liters of absolute ethanol to the reaction kettle, add 200 kg of 2-acrylamido-2-methylpropanesulfonic acid crude product under stirring, control the temperature at 20°C, and filter and separate the solid after stirring for 2 hours. After the solid was dried in vacuo, 198 kg of dried solid was obtained. Dissolve the solid in 700 liters of acetic acid aqueous solution with an acetic acid concentration of 88% by weight, then add 30 kg of activated carbon powder, stir at 35°C for 60 minutes, and filter to obtain a filtrate, which is then crystallized at 5°C for 4 hours After the crystallized solution was filtered and vacuum-dried at 90° C. for 10 hours, 151 kg of 2-acrylamido-2-methylpropanesulfonic acid product was obtained with a yield of 75.5% and a produ...

Embodiment 2

[0076] This example is used to illustrate the modified acrylamide / 2-acrylamido-2-methylpropanesulfonate sodium / sodium acrylate terpolymer and its preparation method according to the present invention.

[0077] Add 250 kg of AM and 750 kg of purified AMPS (mps) and 2330 kg of deionized water into the batching kettle. Under stirring, control the solution temperature to 15°C with frozen brine, and add sodium hydroxide to adjust the pH to 5. Pump the monomer solution into the polymerization tank, add 500 grams of water-soluble azo initiator 2,2'-azo(2-amidinopropane) dihydrochloride and reducing agent N, N, N', N' - 500 grams of tetramethylethylenediamine, deoxygenated by passing high-purity nitrogen for 0.5 h, adding 500 grams of sodium bisulfite and 500 grams of ammonium persulfate, continuing to pass nitrogen until the thermocouple in the polymerization kettle starts to heat up, and the reaction time is 6 hours. Open the ball valve at the bottom of the reactor, press out the ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com