Method for separating and purifying 10-deacetyl baccatin III from Chinese yew branches and leaves

A technology for deacetylation of yew branches and leaves, which is applied in the field of extraction of yew plant components, can solve the problems of low reuse rate and high cost, and achieve the effects of simplification of solvent types, reduction of emissions and treatment, and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

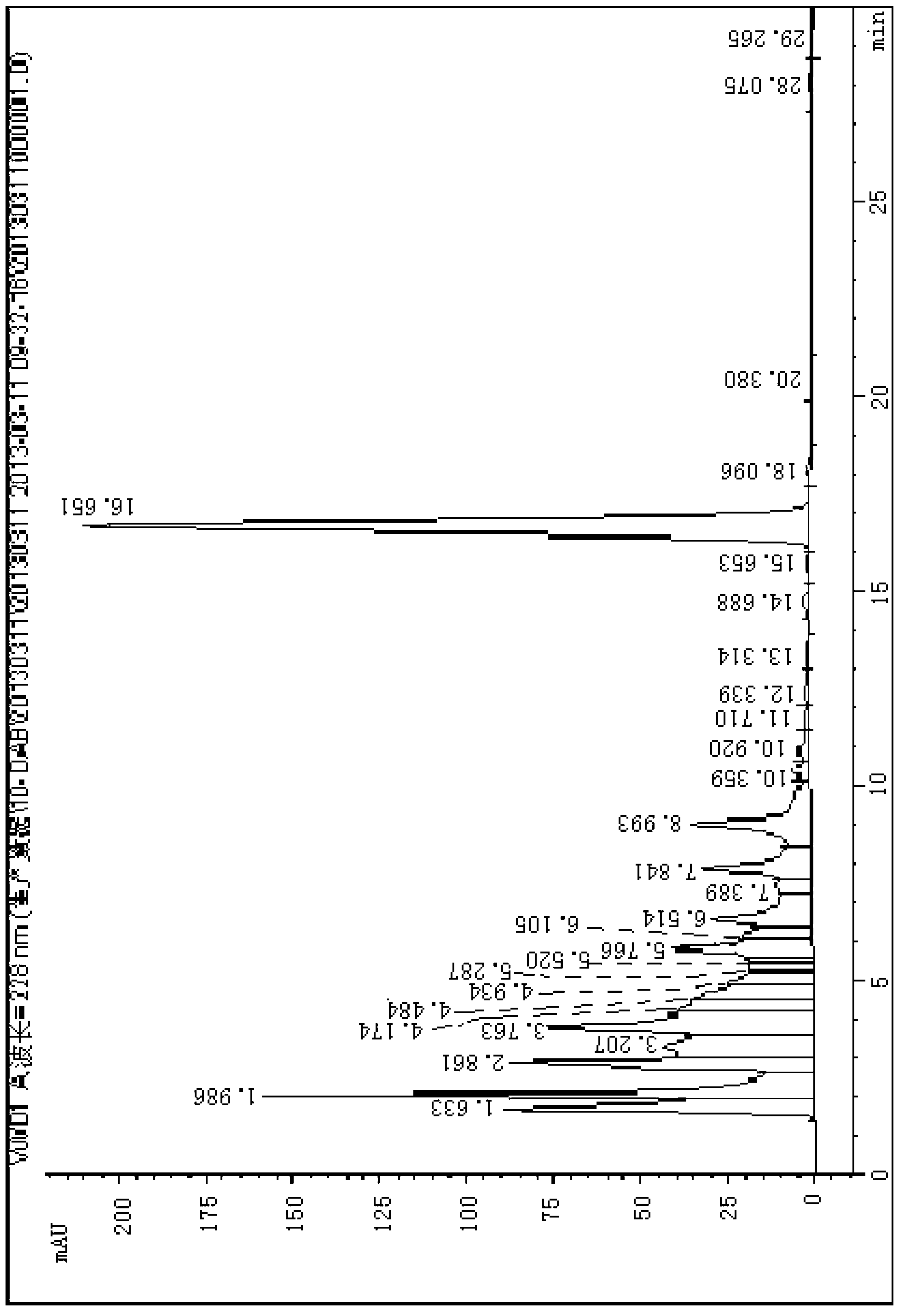

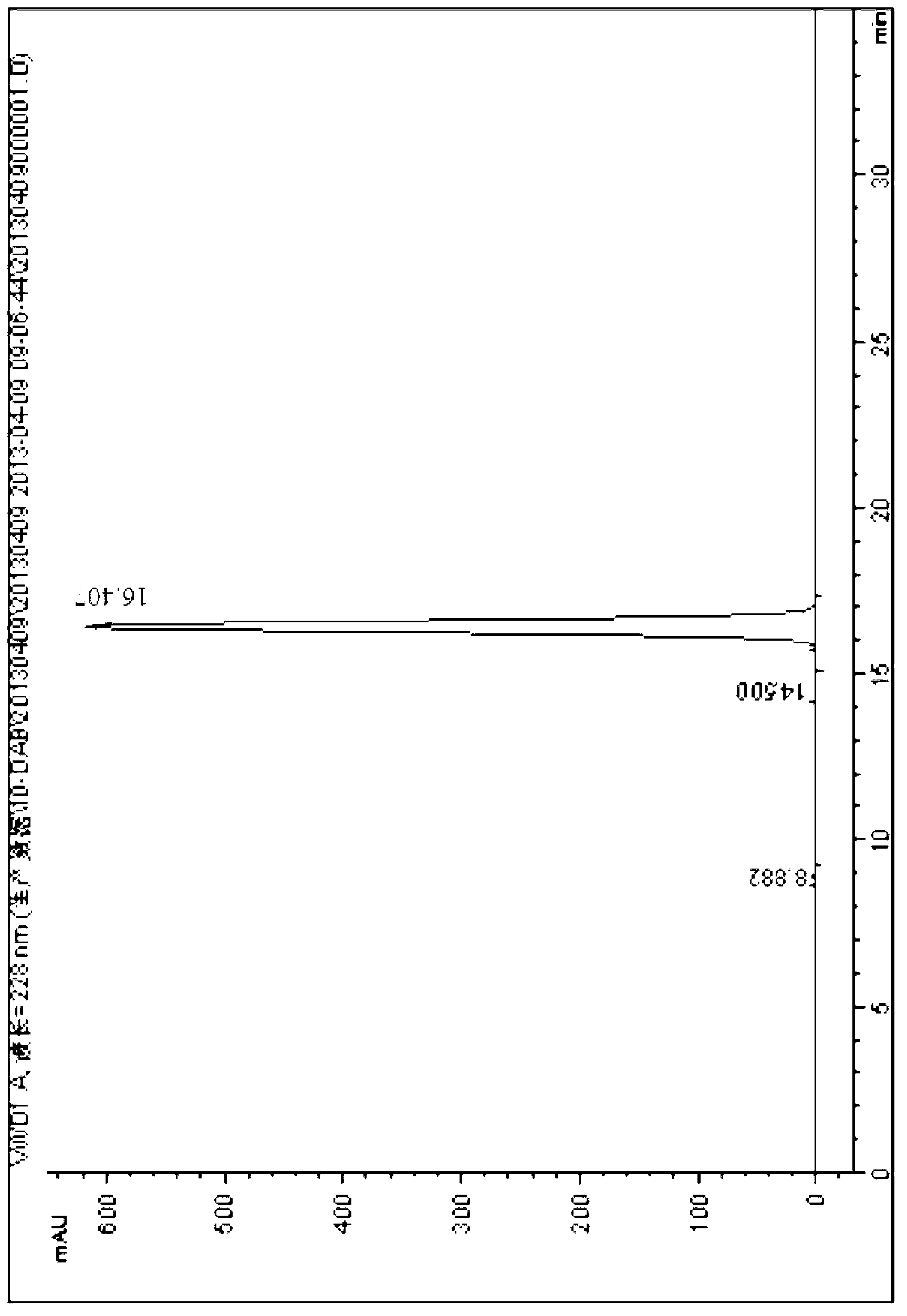

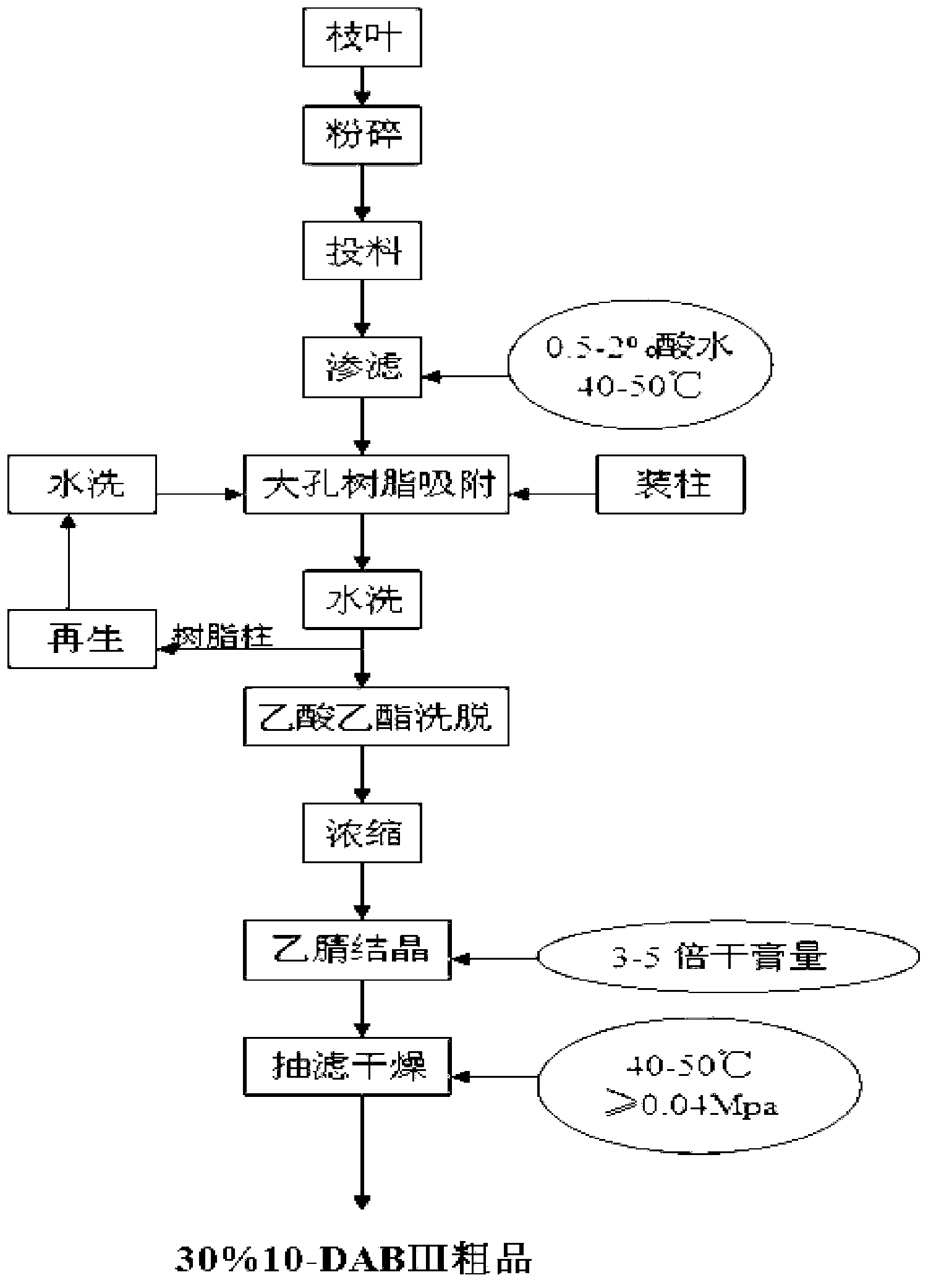

[0053] (1) Take 1 kg of crushed European yew branches and leaves (the content of branches and leaves is 1230ppm), put them into a glass column of 100mm×1000mm, add 0.5% by volume of acetic acid aqueous solution (temperature is 50°C) for diafiltration, and the leachate Combined and stirred evenly, a total of 15L, the effective amount of 10-DABⅢ detected by HPLC was about 1.2g.

[0054] (2) Adsorb leachate with D101 macroporous adsorption resin that has been treated and packed into a 100mm×500mm glass column (resin treatment method is to soak in methanol for 12 hours, and then rinse methanol with drinking water before use). Elute with ethyl acetate after all the adsorption, concentrate and dry the eluent (about 4.5L) to obtain a dry paste of about 35g, add 105ml of acetonitrile to the dry paste to dissolve the crystals at 70°C, let stand at 15°C for 4h, and pump Filter, and dry the filter cake to obtain 3.4 g of crude product, and the detected 10-DABⅢ content is 31.4%.

[0055]...

Embodiment 2

[0057] (1) Take 300kg of crushed European yew branches and leaves and pack them into 6m 3 In the diafiltration tank, add 2% acetic acid aqueous solution (temperature 40°C) for diafiltration, and mix the leachate in batches, with a total of about 5000m 3 , The effective amount of 10-DABⅢ detected by HPLC is about 356g.

[0058] (2) Put the D101 resin into a 600L stainless steel column after being treated according to the method in Example 1, and absorb the leachate. Elute with ethyl acetate after all the adsorption, concentrate and dry the eluent (about 500L) to obtain a dry paste of about 12kg, add 60L of acetonitrile to the dry paste to dissolve the crystals at 60°C, let stand at 15°C for 4h, and then filter with suction , the filter cake was dried to obtain 960 g of crude product, and the detected 10-DABⅢ content was 33.8%.

[0059] (3) Add 30 L of the treated blank reversed-phase stationary phase into a 300×600 high-pressure separation column (the treatment method of the ...

Embodiment 3

[0061] (1) Take 500kg of crushed European yew branches and leaves and pack them into 6m 3 In the diafiltration tank, add 0.5% acetic acid aqueous solution (temperature 40°C) for diafiltration, and mix the leachate in batches, with a total of about 9100m 3 , The effective amount of 10-DABⅢ detected by HPLC is about 601g.

[0062] (2) Adsorb the leachate after regeneration treatment of the resin used in Example 2 (resin regeneration treatment method is to first wash 2 column volumes with liquid caustic soda with a mass percentage concentration of 8%, and then rinse with drinking water until the effluent is neutral and wait use). Elute with ethyl acetate after all the adsorption, concentrate and dry the eluent (about 500L) to obtain a dry paste of about 18kg, add 54L of acetonitrile to the dry paste to dissolve the crystals at 70°C, let stand at 15°C for 4h, and then filter with suction , the filter cake was dried to obtain 1552 g of crude product, and the detected 10-DABⅢ cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com