Low temperature lead-free glass dust and preparation method thereof

A lead-free glass powder, low temperature technology, applied in the field of lead-free glass powder, low-temperature lead-free glass powder and its preparation, can solve the problems of poor wettability, easy crystallization, high softening temperature, etc., and achieve refiring stability Good, good wetting properties, high bond strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A kind of low-temperature lead-free glass powder of the present invention and preparation method thereof, the raw material of lead-free glass powder comprises following component and weight percentage: Bi 2 o 3 30-80%, B 2 o 3 10~60%, ZnO 0~20%, Sb 2 o 3 0~20%,Al 2 o 3 0~10%, alkali metal oxide 0~7%; the basic oxide is Li 2 O.

[0025] The preparation method of low-temperature lead-free glass powder comprises the following steps:

[0026] (1) Weigh the raw materials according to the above components, use a planetary ball mill, and use ethanol as the medium to ball mill for 30 to 60 minutes and mix them evenly, and obtain uniformly mixed oxides after drying;

[0027] (2) After the mixture is melted, pour it into deionized water to obtain glass slag, then dry it, put it into a ball mill jar and mill it in a planetary ball mill;

[0028] (3) Pass through a 300-mesh sieve after ball milling to obtain low-temperature lead-free glass powder.

Embodiment 1

[0033] According to the weight percentage of the composition in Table 1, the ingredients are mixed evenly, and the raw materials are added into the corundum crucible, and heated and melted in a silicon-molybdenum rod resistance furnace at a melting temperature of 1200 ° C and a holding time of 30 minutes.

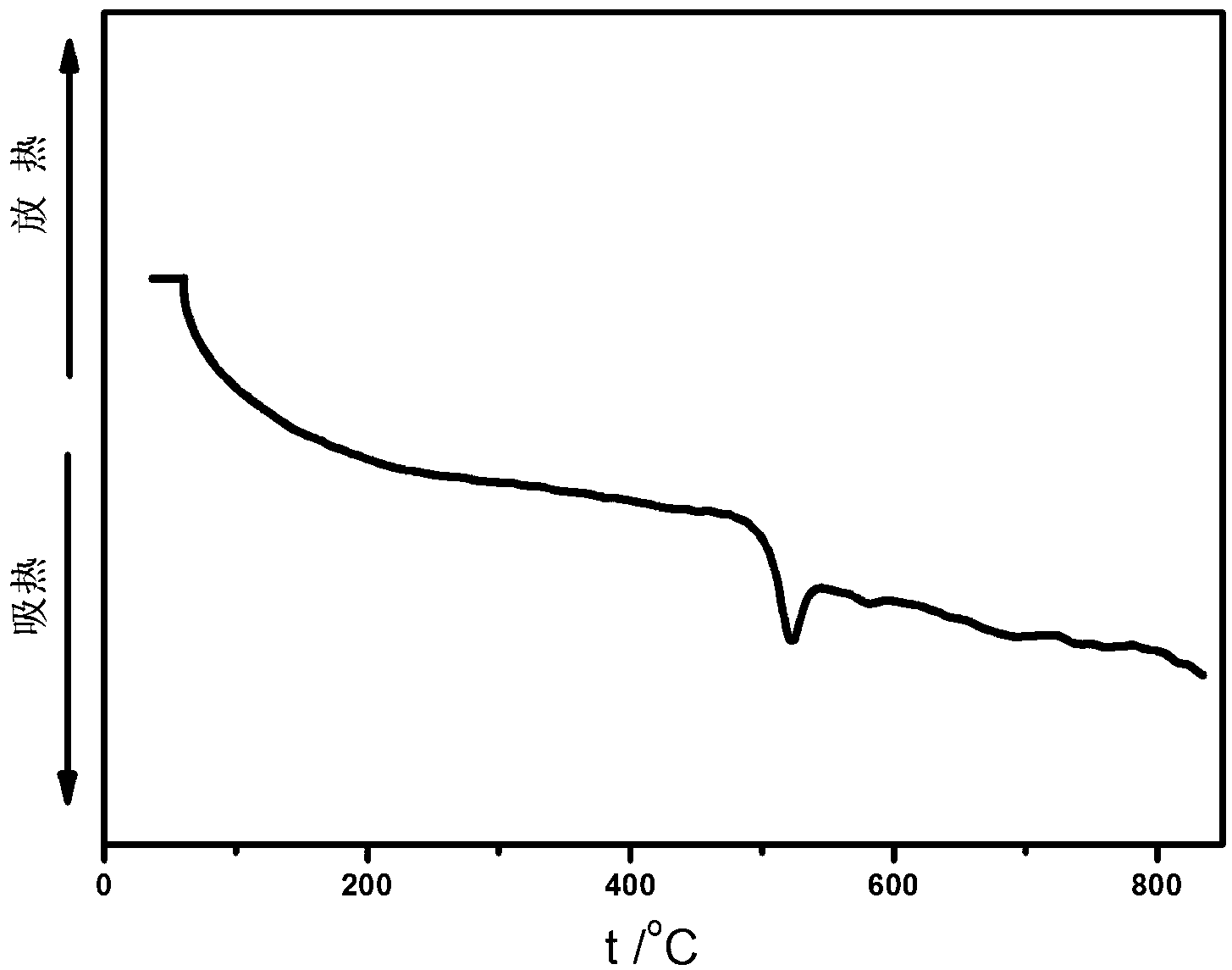

[0034] After the glass is evenly melted, part of it is poured into a preheated stainless steel mold with a size of 55mm×6mm×6mm for molding, and then placed in a muffle furnace for annealing at 450°C, kept for 2 hours and then cooled with the furnace, using a PCY horizontal dilatometer The expansion coefficient of the test sample is shown in Table 1, and the other part is quenched in high temperature water, and ball milled to powder, and sieved through a 300-mesh sieve, and a small amount of powder is taken to test the softening temperature of the glass with a HCT-1 / 2 differential thermal analyzer, as shown in the table 1, the resulting DTA curve is shown in the attached fi...

Embodiment 2

[0036] According to the weight percentage of the composition in Table 1, the ingredients are mixed evenly, and the raw materials are added into the corundum crucible, and heated and melted in a silicon-molybdenum rod resistance furnace at a melting temperature of 1250°C and a holding time of 40 minutes.

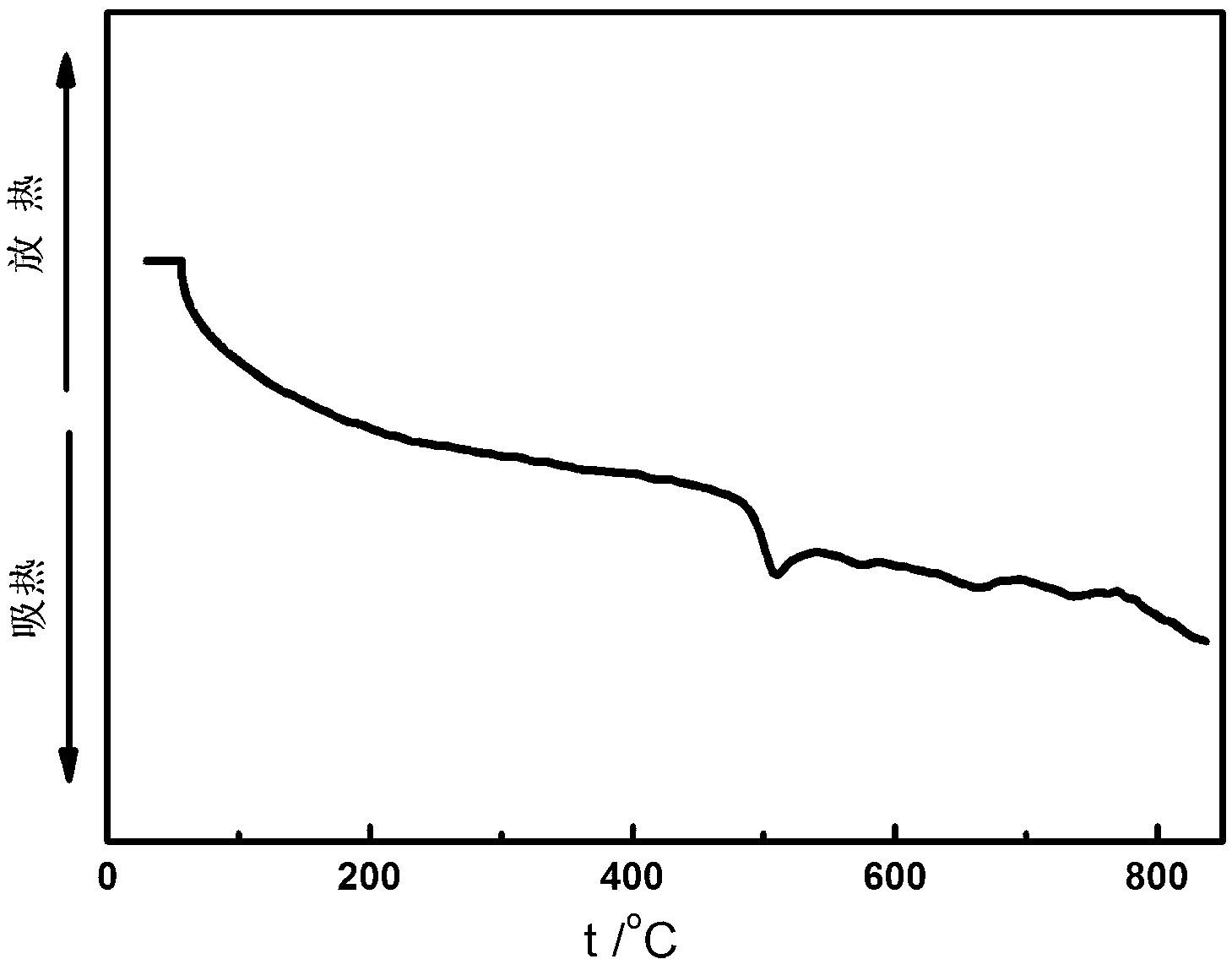

[0037] After the glass is evenly melted, part of it is poured into a preheated stainless steel mold with a size of 55mm×6mm×6mm for molding, and then placed in a muffle furnace for annealing at 450°C, kept for 2 hours and then cooled with the furnace, using a PCY horizontal dilatometer The expansion coefficient of the test sample is shown in Table 1, and the other part is quenched in high temperature water, and ball milled to powder, and sieved through a 300-mesh sieve, and a small amount of powder is taken to test the softening temperature of the glass with a HCT-1 / 2 differential thermal analyzer, as shown in the table 1, the resulting DTA curve is shown in the attached fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com