A novel carbon-based monolithic solid acid catalyst and its preparation and application in the preparation of biodiesel

A solid acid catalyst, biodiesel technology, used in physical/chemical process catalysts, biofuels, fatty acid esterification, etc., can solve the problems of temperature sensitivity, easy swelling, etc., to achieve less loss of acid sites, thermal stability and structure. The effect of good stability and novel preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

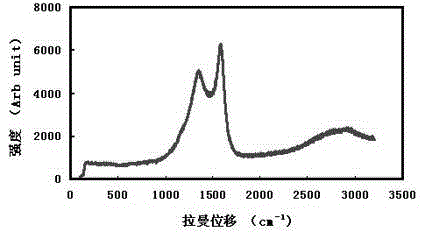

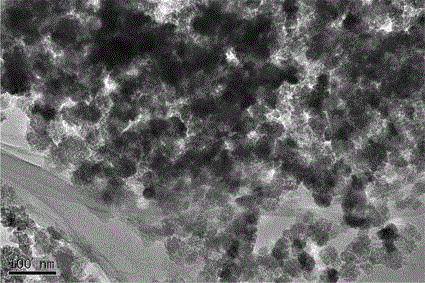

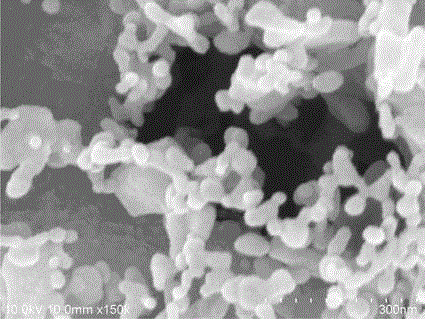

[0045] Dissolve 5 g of ferric nitrate in 8 mL of oleylamine, then heat to 180°C and stir for 60 minutes. The above slurry was uniformly coated on the surface of the stainless steel wire mesh, and then dried under vacuum at 60° C. for 24 hours. Then put the sample into the tube furnace, under the protection of nitrogen (the flow rate of nitrogen is 30mL / min), raise the temperature from room temperature to 750°C, and keep it for 3 hours, and then use H 2 (Hydrogen flow rate 5mL / min) reduction for 3h. Afterwards, it was naturally cooled to room temperature to obtain a stainless steel wire mesh / sheet of catalyst particles. The Raman spectrum of the product is shown in figure 1 , TEM photo see figure 2 , SEM scanning electron microscope photo see image 3 .

[0046] Put the above-mentioned catalyst particle stainless steel wire mesh into a tube furnace, benzene is used as a carbon source, and nickelocene is mixed and dissolved in it, and injected into the tube furnace at 10mL...

Embodiment 2

[0049] Dissolve 10g of ferric chloride in 15mL of oleylamine, then heat to 300°C and stir for 60min. The above slurry was uniformly coated on the surface of the stainless steel wire, and then dried in vacuum at 60°C for 24h. Then put the sample into the tube furnace, under the protection of nitrogen (the flow rate of nitrogen gas is 60mL / min), raise the temperature from room temperature to 750°C, and keep it for 3 hours, and then use H 2 (Hydrogen flow rate 5mL / min) reduction for 3h. Afterwards, it was naturally cooled to room temperature to obtain a stainless steel wire sheet of catalyst particles.

[0050] Put the above-mentioned catalyst particle stainless steel wire into a tube furnace, ethanol is used as a carbon source, and ferrocene is mixed and dissolved in it, and injected into the tube furnace at 10mL / h, and the mixture is formed by Ar+H 2 (60mL / min+10mL / min) gas is carried into the center of the tube furnace, and catalytically cracked at 800°C for 30min to obtain ...

Embodiment 3

[0053] Dissolve 1 g of cobalt nitrate in 4 mL of oleylamine, then heat to 100° C. and stir for 60 minutes. The above slurry was uniformly coated on the surface of the stainless steel wire mesh, and then dried under vacuum at 60° C. for 24 hours. Then put the sample into the tube furnace, under the protection of nitrogen (the flow rate of nitrogen is 30mL / min), raise the temperature from room temperature to 750°C, and keep it for 3 hours, and then use H 2 (Hydrogen flow rate 5mL / min) reduction for 3h. Afterwards, it was naturally cooled to room temperature to obtain a stainless steel mesh of catalyst particles.

[0054] Put the stainless steel mesh of the above catalyst particles into a tube furnace, methanol is used as a carbon source, and cobalt dicene is mixed and dissolved in it, and injected into the tube furnace at 15mL / h, and the mixture is formed by Ar+H 2 (90mL / min+5mL / min) gas is carried into the center of the tube furnace, and catalytically cracked at 800°C for 40m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com