Superfine copper powder and preparation method thereof

A technology of ultra-fine copper powder and powder, which is applied in the field of powder materials, can solve the problems of poor dispersibility and easy agglomeration of products, and achieve the effects of good dispersibility, easy control of copper powder particle size, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Put 5g of analytically pure copper oxide powder, 20g of grinding balls and 10g of water into a stainless steel ball mill tank, and grind for 6 hours on a planetary ball mill at a speed of 600r / min; then, add 2.5g of concentration 80% hydrazine hydrate, and continue to grind for 4 hours at a speed of 400r / min; finally, after filtering and drying the obtained product, ultrafine copper powder particles can be obtained.

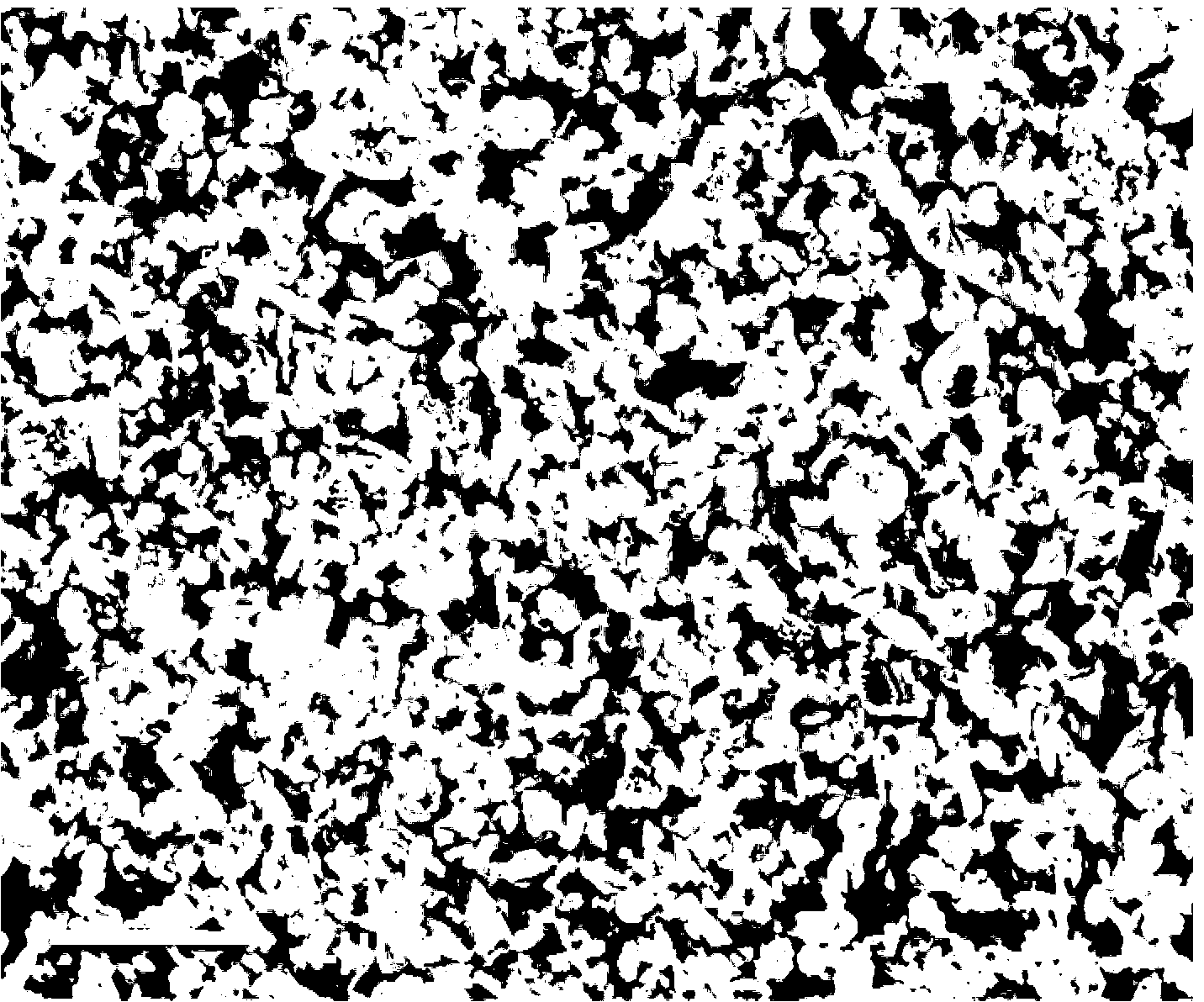

[0055] The surface morphology of the ultrafine copper powder material prepared above was observed with a JSM7100F field emission scanning electron microscope produced by Japan JEOM Company.

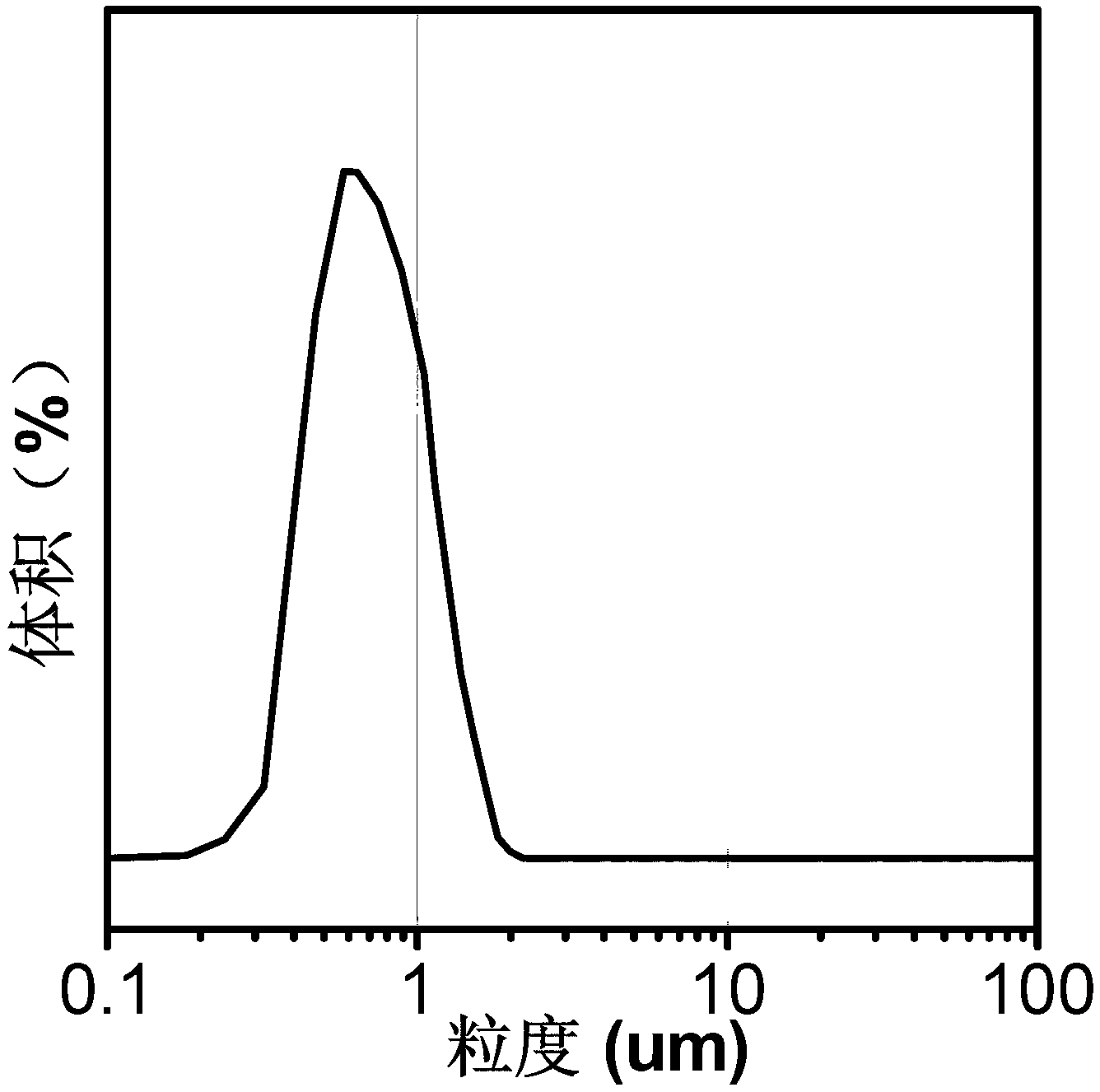

[0056] The particle size analysis of the ultrafine copper powder material prepared above was performed on a Dandong Baite BT-9300Z laser particle size distribution analyzer.

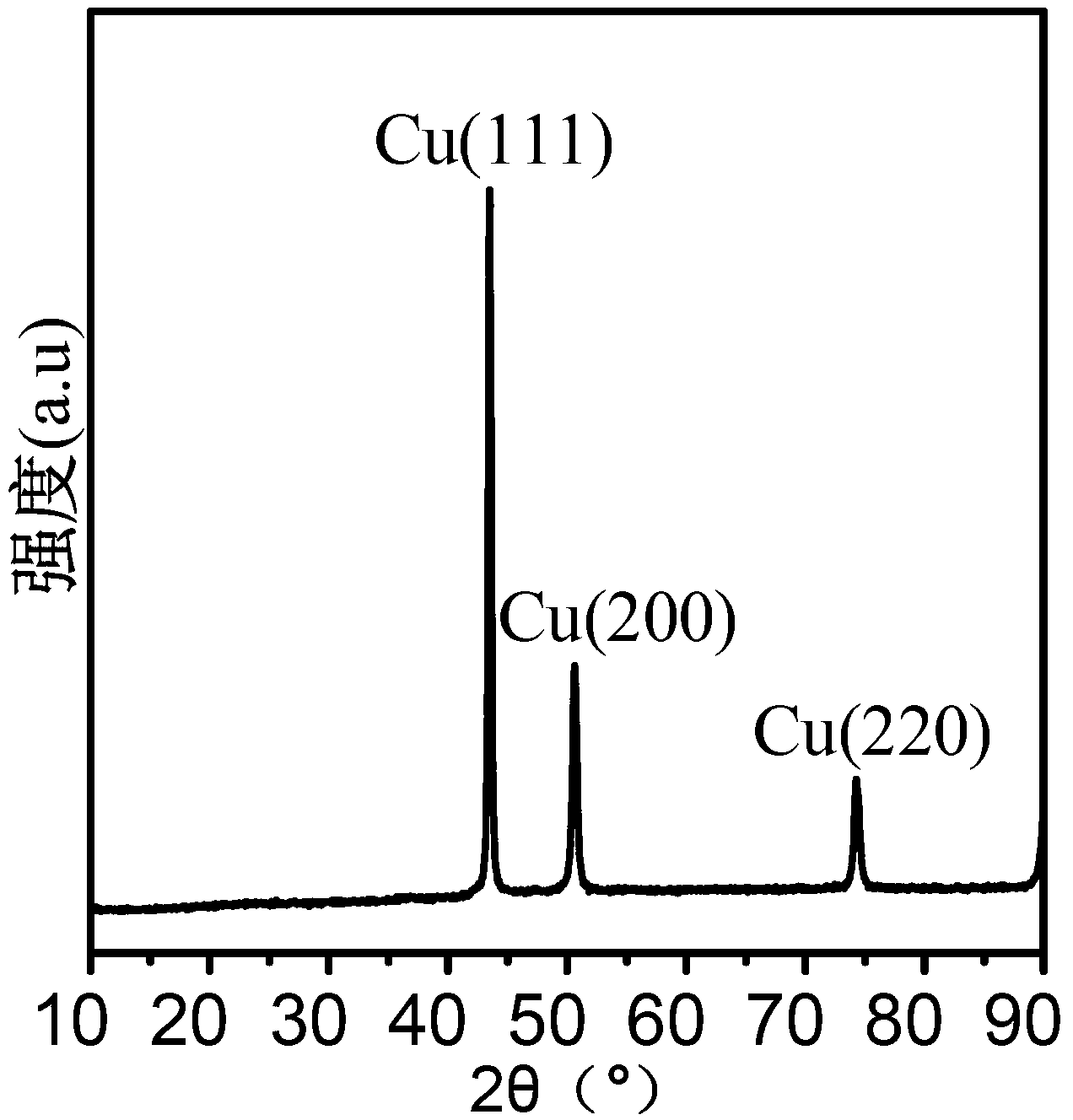

[0057] The ultrafine copper powder material prepared above was subjected to XRD test on the X'Pert PRO MPD multifunctional X-ray diffractometer produced by PANalytical Company (Panalytical) in t...

Embodiment 2

[0062] Put 5g of analytically pure cuprous oxide powder, 20g of balls and 10g of water into a stainless steel ball mill jar, and grind for 10 hours at a speed of 600r / min on a planetary ball mill; then, put the above suspension in a beaker , add 2.5g of hydrazine hydrate with a concentration of 80%, and carry out ultrasonic dispersion in an ultrasonic cleaning machine for 4h; finally, after filtering and drying the obtained product, ultrafine copper powder particles can be obtained.

[0063] Figure 4 This is the SEM picture of the ultrafine copper powder obtained in Example 2. It can be seen from the figure that the particles of the copper powder are amorphous, and the particle size is concentrated in the range of 0.1-1.5 μm, which has good dispersibility.

[0064] Figure 5 It is the particle size analysis diagram of the ultrafine copper powder obtained in Example 2. It can be seen from the figure that the particle size of the ultrafine copper powder is all less than 2 μm, ...

Embodiment 3

[0067] Put 5g of nano-copper oxide powder in a beaker, add 20g of ethanol, add 2.5g of hydrazine hydrate with a concentration of 80%, and carry out ultrasonic dispersion in an ultrasonic cleaning machine for 4 hours; finally, after filtering and drying the obtained product, the super Fine copper powder particles.

[0068] Figure 7 This is the SEM picture of the ultrafine copper powder obtained in Example 3. It can be seen from the figure that the particles of the copper powder are amorphous, and the particle size is concentrated in the range of 0.1-1 μm, which has good dispersibility.

[0069] Figure 8 It is the particle size analysis diagram of the ultrafine copper powder obtained in Example 3. It can be seen from the figure that the particle size of the ultrafine copper powder is all less than 2 μm, and most of the particle diameters are concentrated at 0.7 μm.

[0070] Figure 9 The XRD pattern of the ultrafine copper powder obtained in Example 3, wherein 2θ=43.3°, 2θ=...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com