Technology for extracting lithium by processing lithium ores through high-pressure steaming process

A high-pressure steam, lithium ore technology, applied in the field of metallurgy, can solve the problems of cumbersome alkali recovery process, excessive strong alkali, rising cost, etc., and achieve the effects of convenient lithium extraction, high yield and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

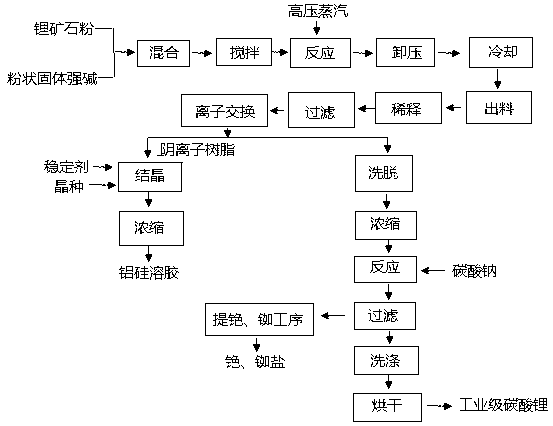

Method used

Image

Examples

Embodiment 1

[0020] (1) Mix lepidolite powder crushed to 100 meshes and powdery solid strong alkali according to the weight ratio of lepidolite powder: strong alkali = 1:0.5, put them into the reactor, start strong stirring, and use the straight-through method to pass through Enter the high-pressure steam, the temperature of the high-pressure steam is 100°C, and the pressure is 0.1MPa. Use the moisture in the high-pressure steam to participate in the reaction, so that the lithium ore powder and the strong alkali react under the action of water vapor at high temperature and high pressure for 2 hours, cool, and discharge;

[0021] (2) The reaction product is diluted with water to a mass percentage concentration of 0.1%, and the diluted material is ion-exchanged with a cation exchange resin to obtain cations in the system, including sodium ions, potassium ions, lithium ions, cesium ions and rubidium ions; the remaining The aluminum silica sol passes through an anion exchange resin, and then ad...

Embodiment 2

[0027](1) Mix lepidolite powder crushed to 700 meshes and powdery solid strong alkali according to the ratio of lepidolite powder: strong alkali = 1: 5 by weight, put them into the reactor, start strong stirring, and adopt the straight-through method. Enter the high-pressure steam, the temperature of the high-pressure steam is 180°C, and the pressure is 1MPa. The water in the high-pressure steam is used to participate in the reaction, so that the lithium ore powder and the strong base are reacted under high temperature and high pressure under the action of water steam for 8 hours, cooled, and discharged;

[0028] (2) The reaction product is diluted with water to a mass percentage concentration of 0.1%, and the diluted material is ion-exchanged with a cation exchange resin to obtain cations in the system, including sodium ions, potassium ions, lithium ions, cesium ions and rubidium ions; the remaining The aluminum silica sol passes through an anion exchange resin, and then adds ...

Embodiment 3

[0034] (1) Mix lepidolite powder crushed to 500 meshes and powdery solid strong base in a weight ratio of lepidolite powder: strong base = 1:3, put them into the reactor, start strong stirring, and use the straight-through method. Enter high-pressure steam, the temperature of the high-pressure steam is 250°C, and the pressure is 4MPa. Use the moisture in the high-pressure steam to participate in the reaction, so that the lithium ore powder and the strong base react under high temperature and high pressure under the action of water vapor for 5 hours, cool, and discharge;

[0035] (2) The reaction product is diluted with water to a mass percentage concentration of 1%, and the diluted material is ion-exchanged with a cation exchange resin to obtain cations in the system, including sodium ions, potassium ions, lithium ions, cesium ions and rubidium ions; the remaining The aluminum silica sol passes through an anion exchange resin, and then adds a small amount of sodium hydroxide as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com