Organosilicone sealing tape for vacuum bag

A technology for sealing tapes and vacuum bags, applied in the direction of adhesives, film/sheet adhesives, non-polymer adhesive additives, etc. The effect of value, good high temperature performance and process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

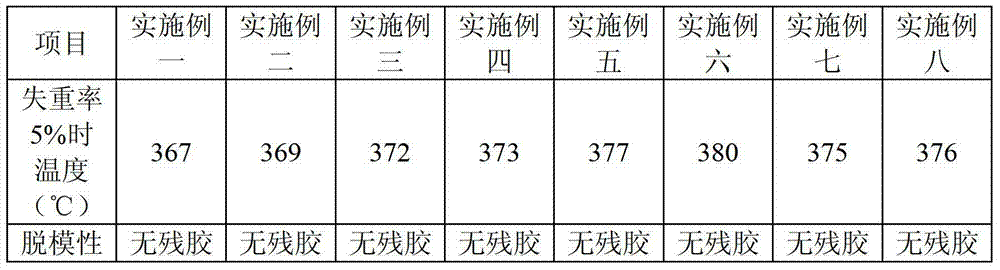

Examples

specific Embodiment approach 1

[0015] Specific embodiment 1: In this embodiment, the silicone vacuum bag sealing tape consists of 100 parts by mass of silicone rubber, 20-70 parts of reinforcing filler, 0.5-3.0 parts of high-temperature vulcanizing agent, 0-100 parts of inert filler, and 0 parts of heat stabilizer. ~15 parts and 5~20 parts of structure control agent;

[0016] Wherein said silicone rubber is methyl phenyl vinyl silicone rubber or methyl vinyl silicone rubber;

[0017] The reinforcing filler is one or more combinations of precipitated silica, fumed silica, and dimethylpolysiloxane-modified fumed silica;

[0018] Described high-temperature curing agent is 2,5-dimethyl-2,5-bis(tert-butyl peroxy)hexane, dicumyl peroxide, 2,4-dichlorobenzoyl peroxide, A combination of one or more of benzoyl peroxide, tert-butyl perbenzoate, and di-tert-butyl peroxide;

[0019] The inert filler is one or more of mica, silicon micropowder, diatomaceous earth, zinc oxide, titanium dioxide, calcium carbonate, quart...

specific Embodiment approach 2

[0024] Embodiment 2: This embodiment differs from Embodiment 1 in that the molecular weight of the silicone rubber is 450,000 to 800,000. Other ingredients are the same as in Embodiment 1.

specific Embodiment approach 3

[0025] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that the silicone resin is methylphenylvinyl silicone rubber. Other compositions are identical with specific embodiment one or two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com