TFT-LCD (thin film transistor-liquid crystal display) array panel structure and production method thereof

A technology of array panel and manufacturing method, which is applied in the field of TFT-LCD array panel structure and its manufacturing, can solve the problems of reducing product yield and production cost, and achieve the effects of reducing production cost, reducing electrode corrosion, and reducing line resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

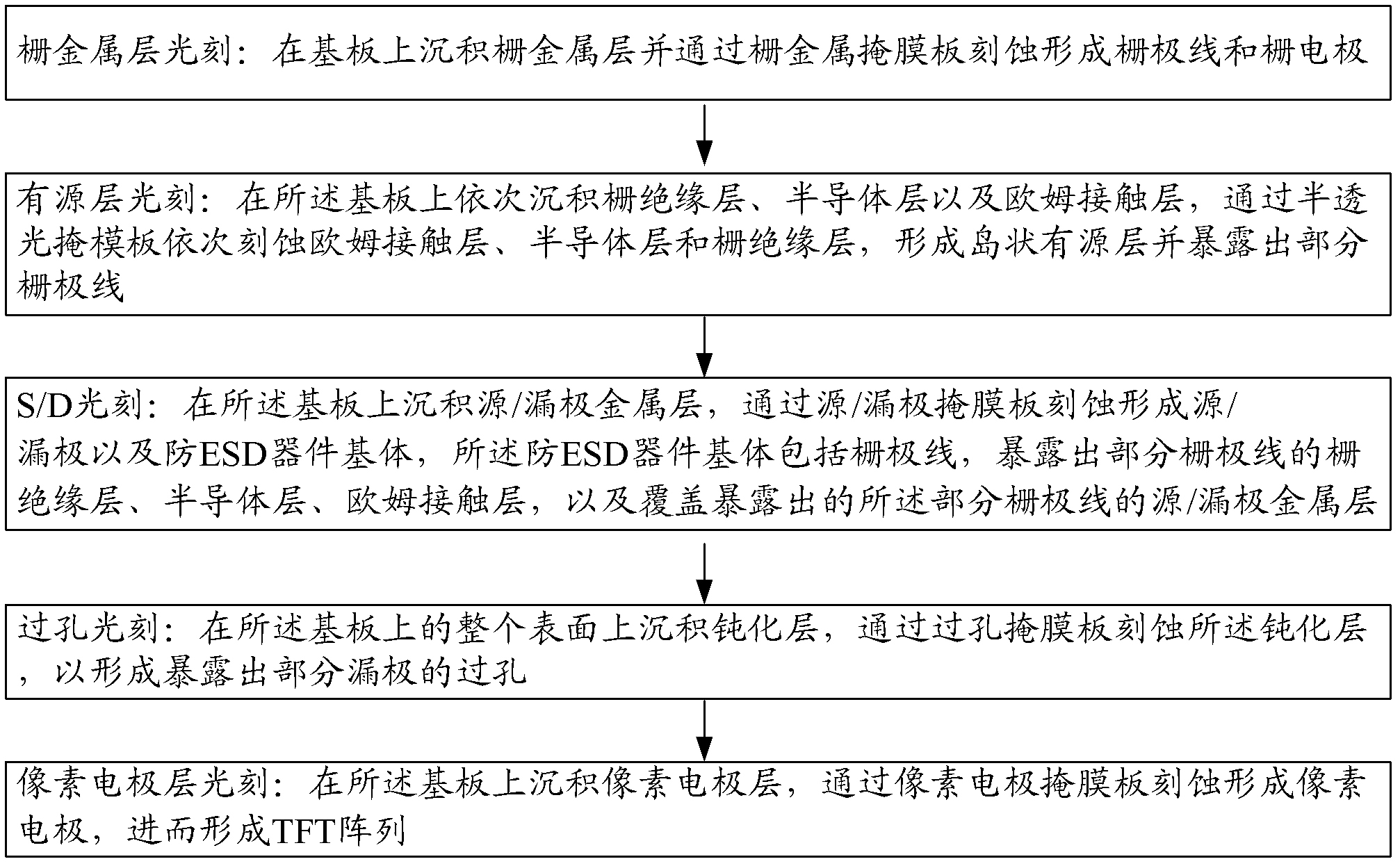

[0038] Such as figure 2 As shown, the present embodiment provides a manufacturing method of a TFT-LCD panel, comprising the following steps:

[0039] Gate metal layer photolithography: deposit a gate metal layer on the substrate and etch through a gate metal mask to form gate lines and gate electrodes;

[0040]Active layer photolithography: sequentially depositing a gate insulating layer, a semiconductor layer and an ohmic contact layer on the substrate, and sequentially etching the ohmic contact layer, semiconductor layer and gate insulating layer through a semi-transparent mask to form an island-shaped active layer (or silicon island) and expose part of the gate line;

[0041] S / D photolithography: Deposit source / drain metal layers on the substrate, form source / drain and anti-ESD device base through source / drain mask etching, and the anti-ESD device base includes gate lines , exposing a gate insulating layer, a semiconductor layer, an ohmic contact layer of a part of the ...

Embodiment 2

[0059] Such as Figure 5 As shown, the present embodiment provides a manufacturing method of a TFT-LCD panel, comprising the following steps:

[0060] Gate metal layer photolithography: deposit a gate metal layer on the substrate and etch through a gate metal mask to form gate lines and gate electrodes;

[0061] Active layer photolithography: sequentially depositing a gate insulating layer, a semiconductor layer, and an ohmic contact layer on the substrate, and sequentially etching the ohmic contact layer, semiconductor layer, and gate insulating layer through an active layer mask to expose part of the gate Wire;

[0062] S / D photolithography: Deposit the source / drain metal layer on the substrate, etch the source / drain metal layer, ohmic contact layer and exposed part of the gate line through the source / drain mask to form Source / drain and anti-ESD device substrate, the anti-ESD device substrate includes a gate line, a gate insulating layer that exposes a part of the gate lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com