Method and device for measuring cable force

A measurement method and tension technology, applied in the field of cable force measurement methods and devices, can solve the problems of large measurement results, complex signal processing, and small application range, and achieve the effects of easy portability and installation, high measurement accuracy, and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

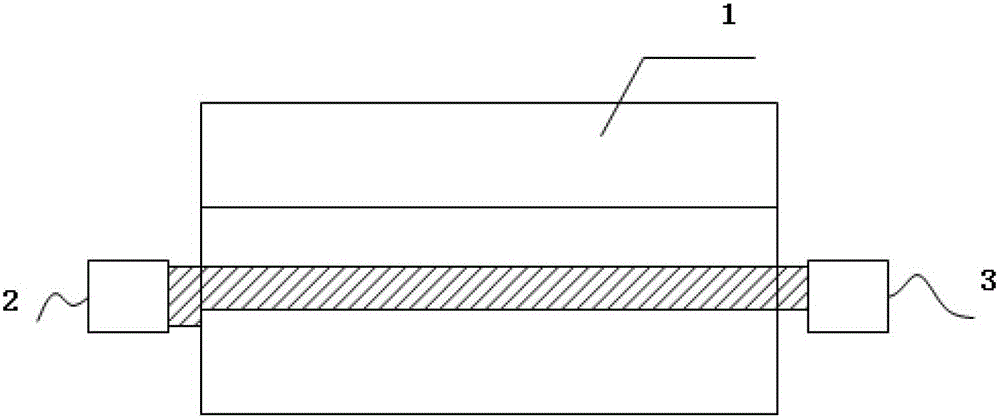

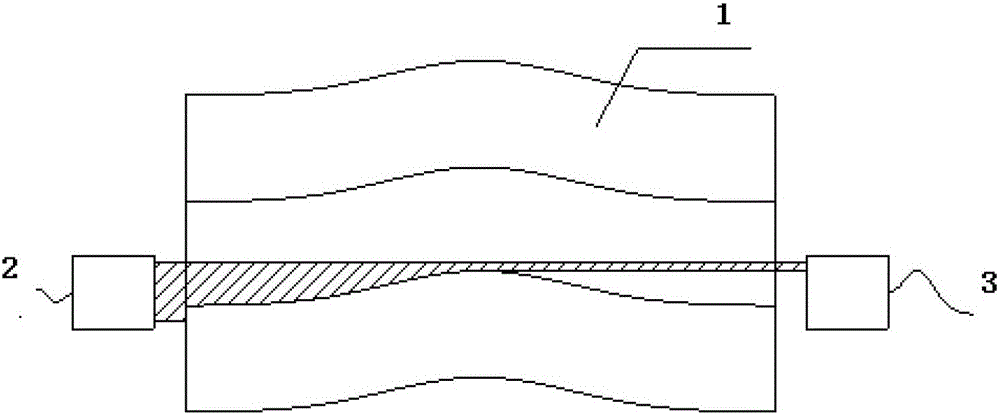

[0042] Such as figure 1 As shown, a cable force measuring device includes a pin shaft 1, a lug plate 5, an axial through hole is opened on the axial center axis of the pin shaft 1, and an optical measurement system is symmetrically placed at both ends of the axial through hole At the transmitting end and the receiving end, the measurement plane of the optical measurement system is coplanar with the axial axis of the pin shaft and the load acting direction, and the lug plate is provided with a limit device connected to the pin shaft.

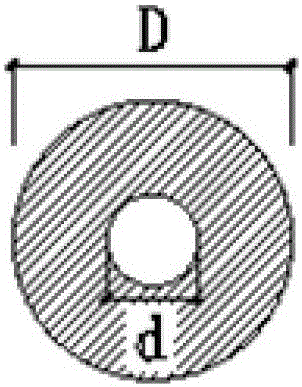

[0043] Such as image 3 As shown, the diameter d of the axial through hole is more than 10mm, and the area of the axial through hole accounts for less than or equal to 12% of the pin shaft area. The pin shaft section moment of inertia with the axial through hole and the pin without the axial through hole The ratio of the moment of inertia of the shaft section is ≥97.5%.

[0044] The resolution of the optical measurement system is less than or equal ...

Embodiment 2

[0057] 1. Calibration of standard test pieces in a factory environment;

[0058] A cable force measurement method includes the following steps:

[0059] S1 preprocesses the pin shaft 1 and the lug plate 5;

[0060] An axial hole is opened at the central axis of the pin shaft, and a limit device is set at the lug plate to connect the pin shaft so that the plane of the laser light curtain and the pulling force direction of the cable are coplanar. The limit device is not limited. The lug plate in this embodiment Setting the limit device to connect the pin shaft specifically includes: two pins are arranged at the pin shaft, two limit small grooves are opened on the lug plate, and the pin and the limit small groove match. In the actual structural force, Existing pin shafts will all rotate freely relative to the lug plate. Since the measuring instruments are all installed at the pin shaft, when the pin shaft rotates, the plane of the laser light curtain and the force direction of the cabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com