Method for preparing antistatic filter material

An antistatic and filter material technology, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve the problems of limited filter material application conditions, limited temperature and corrosion tolerance, deflagration, etc., and achieve expanded application conditions , low surface and bulk resistance, good tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0021] A preparation method of antistatic filter material, comprising the following steps:

[0022] 1) Preparation of plain felt

[0023] The glass fiber, aramid fiber and polyimide fiber are mixed in a ratio of 40:5:1, and the weight is 460g / m after opening, mixing, carding, laying and netting. 2 Glass fiber base cloth and needle punching, the final total weight is 860g / m 2 Composite filter material plain felt.

[0024] 2) Configuration of treatment agent

[0025] The mass percentage formula of the treatment agent is: polytetrafluoroethylene emulsion 8%, acrylate emulsion 8%, silicone oil 3.2%, water 80.8%.

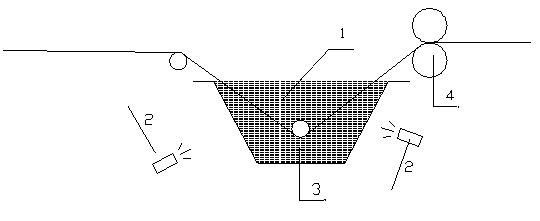

[0026] After mixing the above materials evenly, add them into the bucket, mix the nano-scale graphene powder and the above-mentioned treatment agent in a ratio of 1:4, and then stir the glue solution through a grinder until it is evenly mixed to obtain a mixed solution. figure 1 It is a schematic diagram of the mixed solution glue tank in the present invention. ...

example 2

[0033] Another preparation method of antistatic filter material comprises the following steps:

[0034] 1) Preparation of plain felt

[0035] Preparation of plain felt: The polyphenylene sulfide fiber is opened, mixed, carded, laid, and combined through a series of non-woven equipment, and the weight is 127g / m 2 The polyphenylene sulfide fiber base cloth is needle-punched to obtain a total grammage of 550g / m 2 Polyphenylene sulfide cellulose felt. During singeing treatment, adjust the liquefied gas flow rate to 1.8-2.2, and observe the flame color as blue short flame. The speed of the main machine is 20~25m / min, and the treated felt surface should have no short fiber fluff.

[0036] 2) Configuration of treatment agent

[0037] The mass percentage formula of the treatment agent is: polytetrafluoroethylene emulsion 6%, acrylate emulsion 10%, water 84%.

[0038] After mixing the above materials evenly, add them to the bucket, dilute the graphite milk and water at a ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com