Nano zirconium dioxide with high specific surface area and synthesis method thereof

A nano-zirconia, high specific surface area technology, applied in zirconia, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of reducing the specific surface area of products, amorphous, low specific surface area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

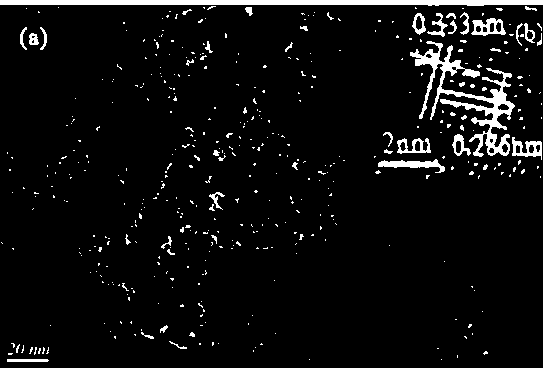

Image

Examples

Embodiment approach 1

[0018] Weigh 11.14g cyclohexanol and put it into a beaker, and get another 0.959g of Zr(OC 4 h 9 ) 4 Drop into a beaker, mix and stir the two solutions for 10 minutes, pour into a 30ml weighing bottle; then put the weighing bottle containing the above mixed solution into a polytetrafluoroethylene liner pre-filled with 15ml distilled water, and seal it in In a stainless steel reactor, react in an oven at 120°C for 24 hours; take it out, cool the reactor with cold water, wash the solid product with ethanol, centrifuge, and dry it in an oven at 60°C for 12 hours. The crystal phase of the obtained sample is a tetragonal phase, and the grain size is 2.4nm, the BET surface area is 399 m 2 g -1 .

Embodiment approach 2

[0020] Weigh 11.14g cyclohexanol and put it into a beaker, and get another 0.959g of Zr(OC 4 h 9 ) 4 Drop into a beaker, mix and stir the two solutions for 10 minutes, pour into a 30ml weighing bottle; then put the weighing bottle containing the above mixed solution into a polytetrafluoroethylene liner pre-filled with 15ml distilled water, and seal it in In a stainless steel reactor, react in an oven at 140°C for 24 hours; take it out, cool the reactor with cold water, wash the solid product with ethanol, centrifuge, and dry it in an oven at 60°C for 12 hours. The crystal phase of the obtained sample is a tetragonal phase, and the grain size is 2.9nm, the BET surface area is 433 m 2 g -1 .

Embodiment approach 3

[0022] Weigh 11.14g cyclohexanol and put it into a beaker, and get another 0.959g of Zr(OC 4 h 9 ) 4 Drop into a beaker, mix and stir the two solutions for 10 minutes, pour into a 30ml weighing bottle; then put the weighing bottle containing the above mixed solution into a polytetrafluoroethylene liner pre-filled with 15ml distilled water, and seal it in In a stainless steel reactor, react in an oven at 160°C for 24 hours; take it out, cool the reactor with cold water, wash the solid product with ethanol, centrifuge, and dry it in an oven at 60°C for 12 hours. The crystal phase of the obtained sample is tetragonal and monoclinic coexistence, the grain size is 3.8nm, and the BET surface area is 188 m 2 g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com