Titanium aluminum oxide thin film and preparation method and application thereof

A technology of titanium thin film and aluminum oxide, which is applied in the field of aluminum oxide titanium thin film and its preparation, can solve the problems of high operating cost and unsuitable gate dielectric layer materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further specifically described below by way of examples.

[0028] A kind of preparation of aluminum oxide titanium film, concrete steps are as follows:

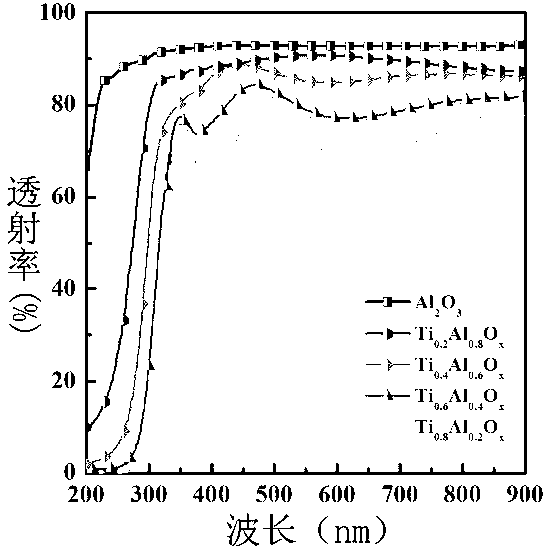

[0029] (1) Preparation of Al-Ti precursor solution

[0030] With ethylene glycol monomethyl ether as solvent, aluminum sec-butoxide Al(C 4 h 9 O) 3 Dissolved therein, after stirring for 0.5 hours to form a clear solution, tetrabutyl titanate Ti(C 4 h 9 O) 4 Dissolve in it, stir for 0.2 hours to a clear solution, then add concentrated hydrochloric acid with a concentration of 38% to it, shake vigorously, stir for 4 hours, then let it stand for 48 hours to form a gel. Wherein the volume ratio of ethylene glycol monomethyl ether and concentrated hydrochloric acid is 10:1, the molar ratio of Al ion and Ti ion in the solution is 1.0:0-0.2:0.8, and the molar concentration of Al ion is 0.6M.

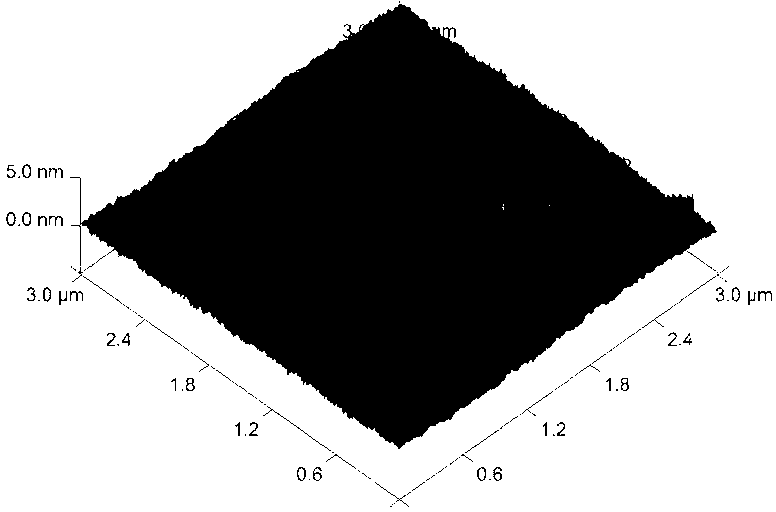

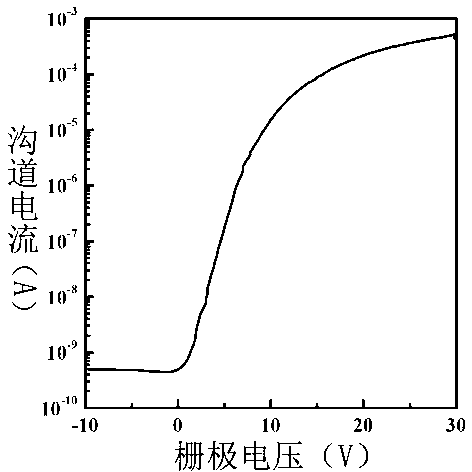

[0031] (2) Preparation of aluminum oxide titanium film

[0032] Spin-coat the aluminum-titanium precu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com