Hydraulic spotting mould clamping type liquid forging squeeze casting machine

A squeeze casting machine and liquid die forging technology, which is applied in the field of squeeze casting machines, can solve problems such as unstable clamping force, easy air entrainment, and overload of tie rods, so as to improve product quality and yield, and reduce workpiece air entrainment , Increase the effect of clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The application of the present invention will be described in detail below in conjunction with the accompanying drawings.

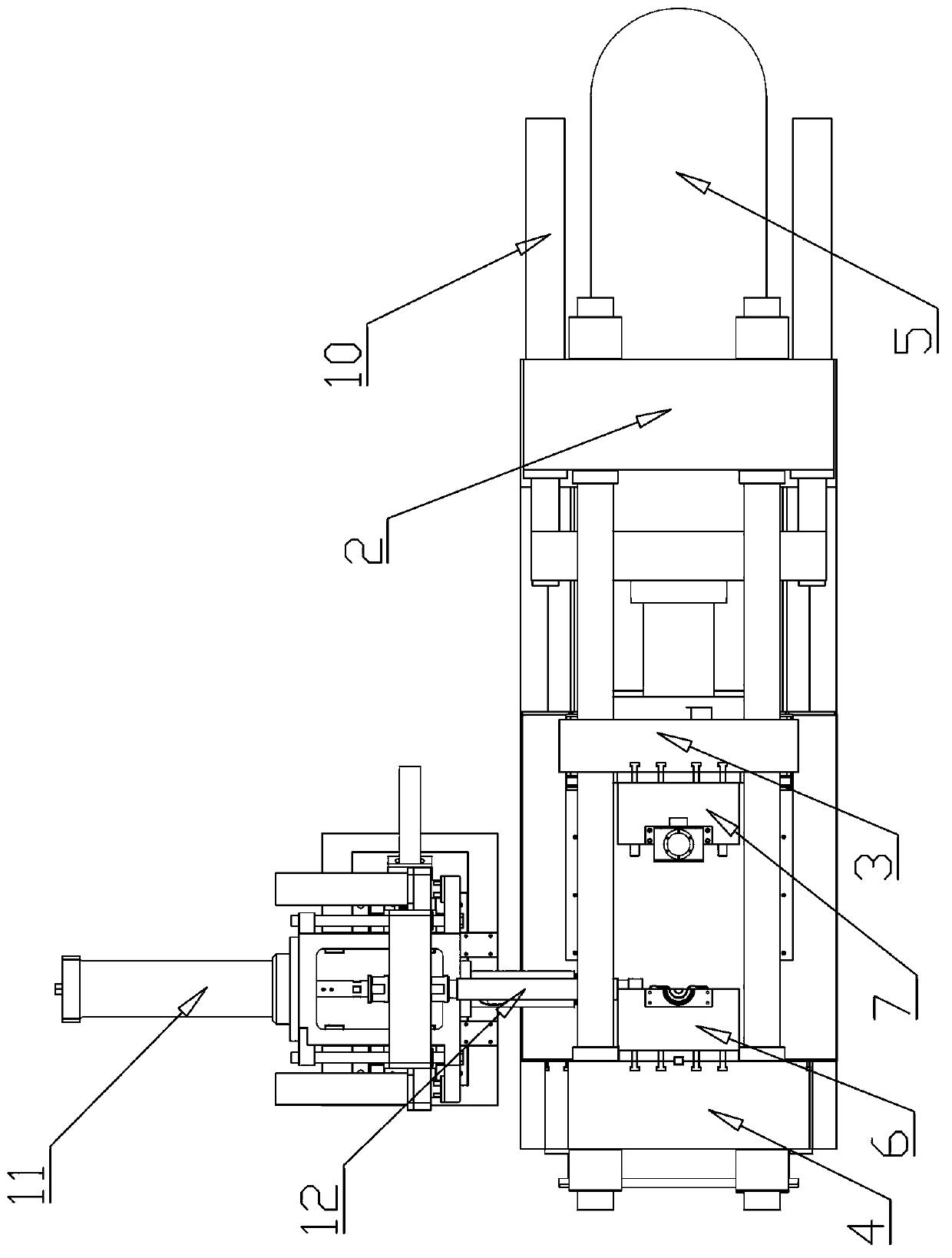

[0020] refer to Figure 1 to Figure 5 , a hydraulic mold clamping liquid die forging squeeze casting machine, which includes a frame 1, on which a front seat 4, a movable template 3 and a rear seat 2 are sequentially installed along the horizontal direction, and the front seat 4, the movable template 3 and the back seat 2 are successively penetrated by the green column 9, the fixed mold 6 is installed on the front seat 4, the movable mold 7 is installed on the movable template 3, and the mold clamping vertical plunger cylinder 5 is installed at the central position of the rear seat 2 , the mold clamping vertical plunger 50 of the mold clamping vertical plunger cylinder 5 is directly or indirectly connected with the movable template 3 and then smoothly pushes the movable template 3 along the Green column 9 to move toward the fixed mold 6 and makes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com