Preparation method of graded zinc stannate macroporous materials

A macroporous material, zinc stannate technology, applied in nanotechnology, chemical instruments and methods, tin compounds, etc. for materials and surface science, to achieve high photoelectric conversion efficiency, fast reproducibility, and abundant raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

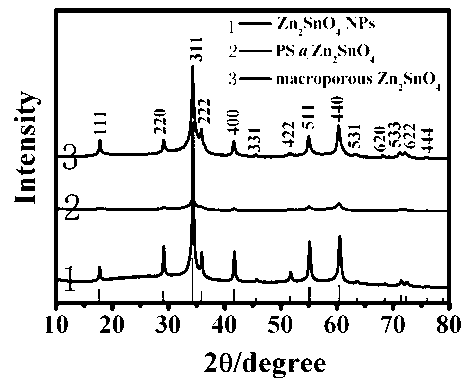

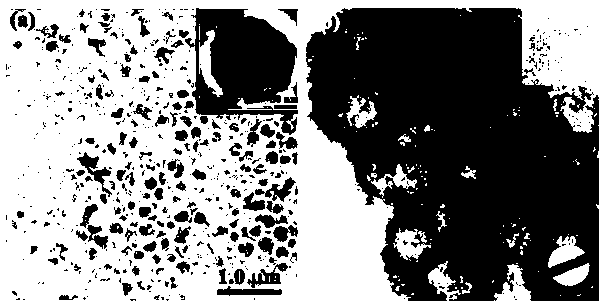

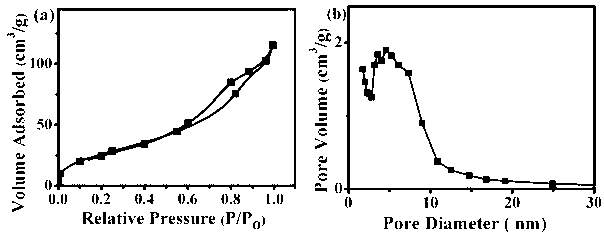

[0052] Embodiment 1 Synthesis of graded zinc stannate macroporous material

[0053] Synthesis of PS emulsion: measure 670 mL H 2O was added to a 1000 mL three-necked flask, heated to 95°C and kept at a constant temperature, and then N 2 After 10 mins, add weighed 42g of styrene, continue to stir for 15 min, add 50 mL of 0.29 M potassium persulfate, and react for 24 h under stable conditions to obtain a 200 nm PS emulsion.

[0054] S1. Weigh 1.4024g SnCl respectively 4 ·5H 2 O, 1.756g Zn(CH 3 COO) 2 2H 2 O was added to a 100 mL beaker, and 16 mL of the prepared 200 nm PS emulsion (0.087 g / mL), 16 mL of 1,2-propanediol, and 32 mL of H 2 O and 16 mL of diethanolamine were added to the beaker in turn to make the pH value alkaline, and the stirring was continued for 30 min to make it a uniform solution; then all the solution was transferred to a 100 mL polytetrafluoroethylene reactor, and the reaction Seal the stainless steel jacket of the kettle tightly, put it in an oven, ...

Embodiment 2

[0060] Slurry preparation:

[0061] Get 1g of the graded zinc stannate macroporous material synthesized by Example 1 or the zinc stannate nanoparticles synthesized by Comparative Example 1, and add to 0.2 mL glacial acetic acid, 3 g terpineol, 0.5 g ethylcellulose, 9 mL In the solution mixed with absolute ethanol, after stirring for 24 hours, ultrasonically treat the stirred slurry for 20 minutes, then further disperse it, grade zinc stannate macroporous material slurry or zinc stannate nanoparticle slurry, and seal it for later use .

[0062] Print the graded zinc stannate macroporous material slurry on the FTO conductive glass by screen printing, brush the graded zinc stannate macroporous material slurry, and heat-treat it in a program-controlled muffle furnace at 500°C for 1 hour , cooled to room temperature, soaked in 40 mM TiCl at 70 °C 4 in aqueous solution for 30 min, from TiCl 4 Zn is removed from the solution 2 SnO 4 Wash the working electrode three times with di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com