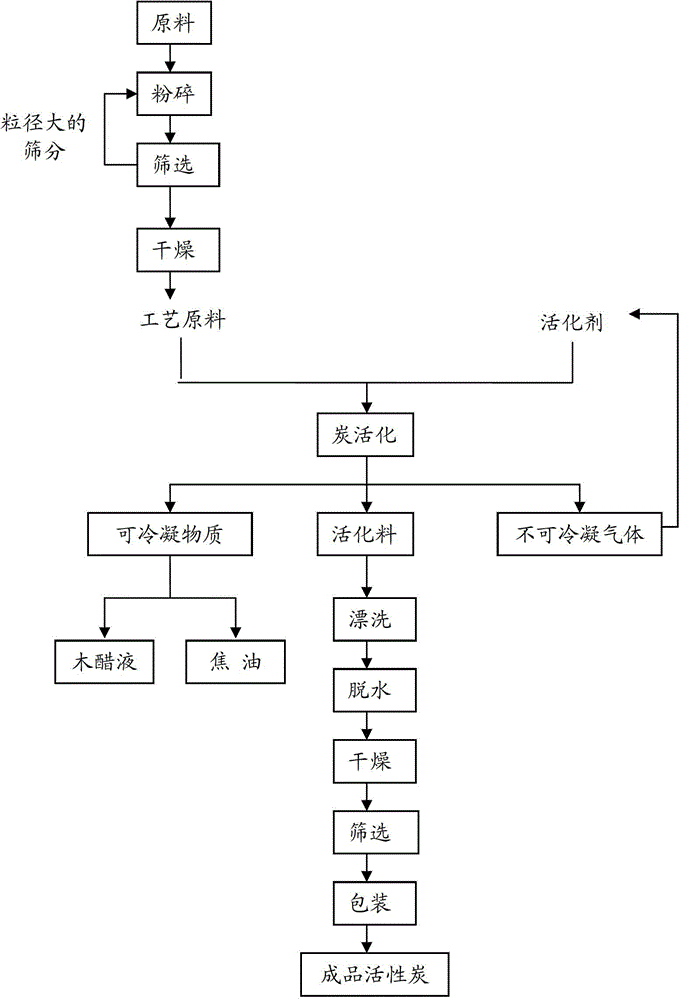

Activated carbon production equipment and method for applying the equipment to production of activate carbon, pyroligneous liquor, tar and wood gas

A technology for activated carbon production and production of activated carbon, applied in chemical instruments and methods, coke ovens, biofuels, etc., can solve the problems of reduced energy utilization, high energy consumption of activated carbon, high processing costs, etc., to achieve reduced energy consumption, complete combustion, Easy to deliver effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

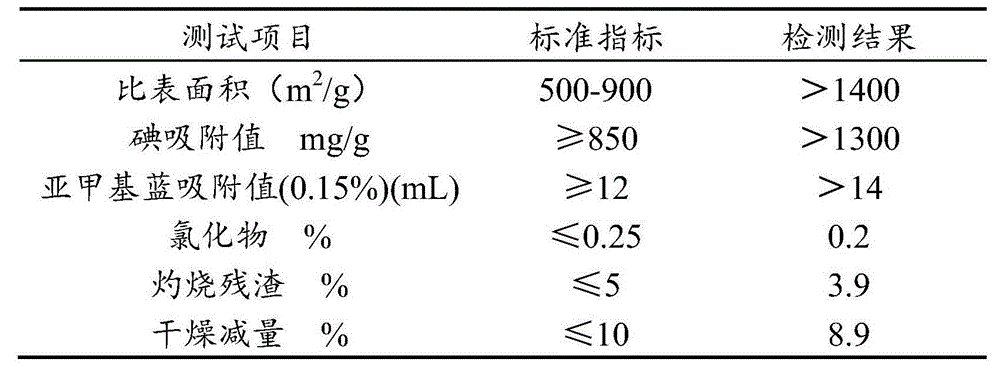

Examples

Embodiment 1

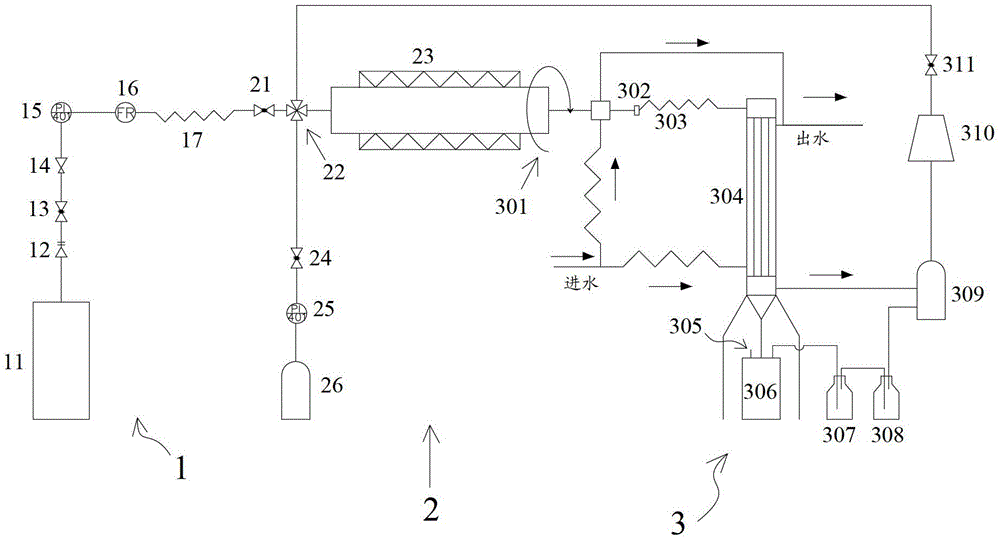

[0047] This embodiment is used to describe the equipment for the production of activated carbon of the present invention in detail.

[0048] Depend on figure 1 As shown, an activated carbon production equipment includes a steam generating device 1, a high-temperature pyrolysis reaction device 2, and an integrated condensing device 3, and the above devices are connected to each other in turn.

[0049] The steam generating device 1 mainly includes a fully automatic electric heating steam generator 11, and the steam generated passes through a safety valve 12, a ball valve I 13, a pressure reducing valve 14, a first pressure gauge 15, and a flow meter 16 to form steam with relatively stable pressure and flow. Link to each other with the ball valve II 21 in the high temperature pyrolysis reaction device 2 by the first steel wire bellows 17; Steam enters in the rotary kiln 23 through the four-way valve 22 that links to each other with this ball valve II 21 in the high temperature py...

Embodiment 2

[0052] see figure 1 and figure 2 .

[0053] (1) Raw material preparation and program setting stage: put the processed wood chips into the rotary furnace 23, close the feeding port, and set the heating rate and temperature range of the rotary furnace 23. Among them, the first stage: the heating rate is 10°C / min, and the temperature range is 0-600°C; the second stage: the heating rate is 10°C / min, and the temperature range is 600-1200°C; the third stage: stop heating and start the cooling program.

[0054] (2) Charcoal activation and reactant collection stage: open the ball valve IV 24, close the ball valve II 21, open the protective gas entering from the protective gas storage tank 26, and react the high-temperature waste gas produced in the first stage by condensation The swivel sleeve 301 and the quick-connect clamp 302 are introduced into the integrated condensing device 3 by the second steel wire bellows 303, pass through the integrated cooling water tank 304, collect th...

Embodiment 3

[0057] (1) Raw material preparation and program setting stage: put the processed wood chips into the rotary furnace 23, close the feeding port, and set the heating rate and temperature range of the rotary furnace 23. Among them, the first stage: the heating rate is 5°C / min, and the temperature range is 0-500°C; the second stage: the heating rate is 10°C / min, and the temperature range is 500-1200°C; the third stage: stop heating and start the cooling program.

[0058] (2) Charcoal activation and reactant collection stage: open the ball valve IV 24, close the ball valve II 21, open the protective gas entering from the protective gas storage tank 26, and react the high-temperature waste gas produced in the first stage by condensation The swivel sleeve 301 and the quick-connect clamp 302 are introduced into the integrated condensing device 3 by the second steel wire bellows 303, pass through the integrated cooling water tank 304, collect the condensate collector 306, and collect th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com