Preparation method of horizontal array carbon nano tube

A technology of carbon nanotubes and arrays, which is applied in the field of preparation of controllable ultra-long horizontal array carbon nanotubes, can solve the problems of long preparation period, difficult control, cumbersome operation, etc., and achieve the effect of easy control, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

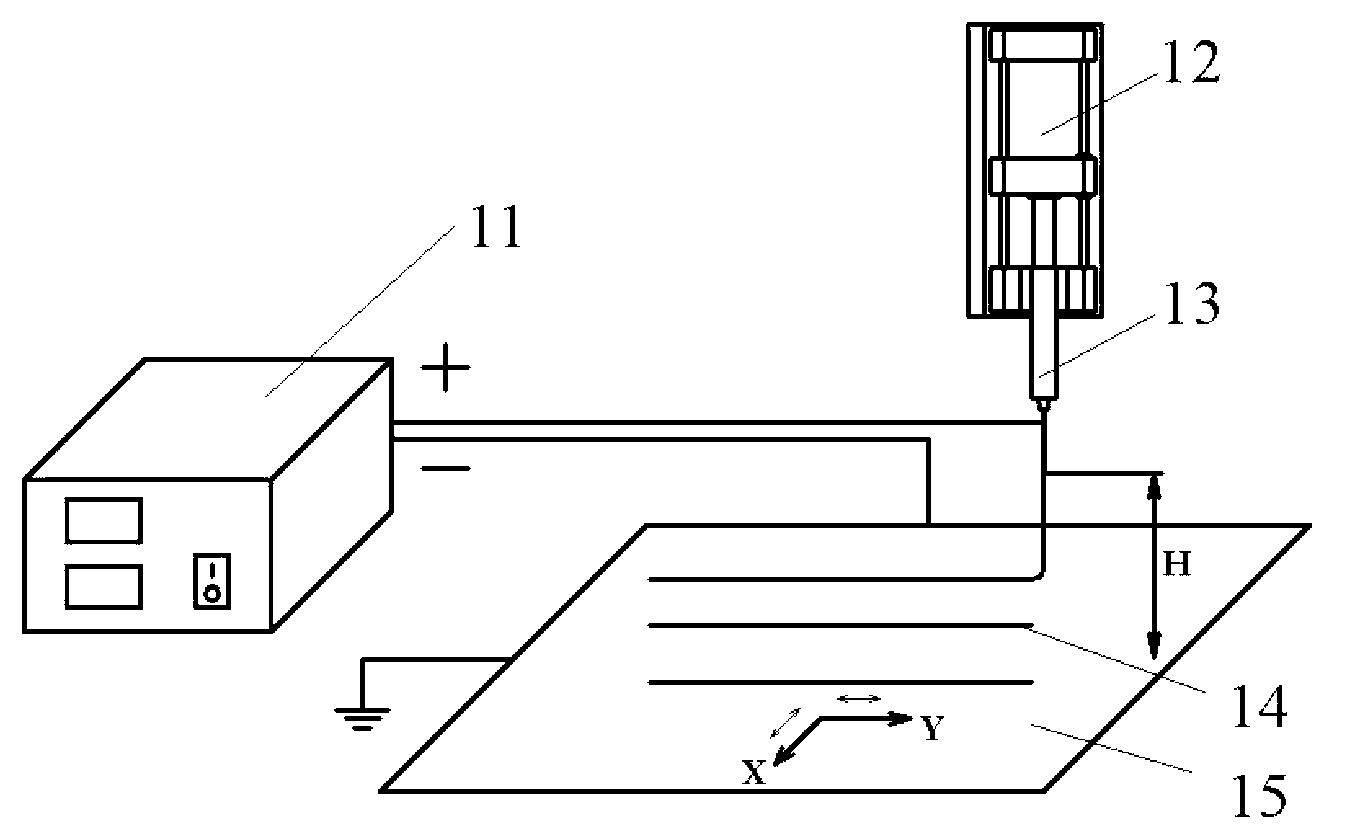

[0031] 0.001mol / L of FeCl 3 Mix the ethanol solution with the PEO solution and stir evenly, suck 2ml of the above solution with the needle tube 13 and install it in the precision syringe pump 12 ( figure 1), using the principle of near-field electrospinning to directly write catalyst nanowires 14 with a diameter of 100nm on the Si substrate, the liquid supply rate of the precision syringe pump 12 used is 100μl / h, the voltage of the DC high-voltage power supply 11 is 4.5kV, the needle and the substrate The distance between them is 2mm. exist figure 1 In , mark H is the distance between the needle tip of the needle tube 13 and the base 15 .

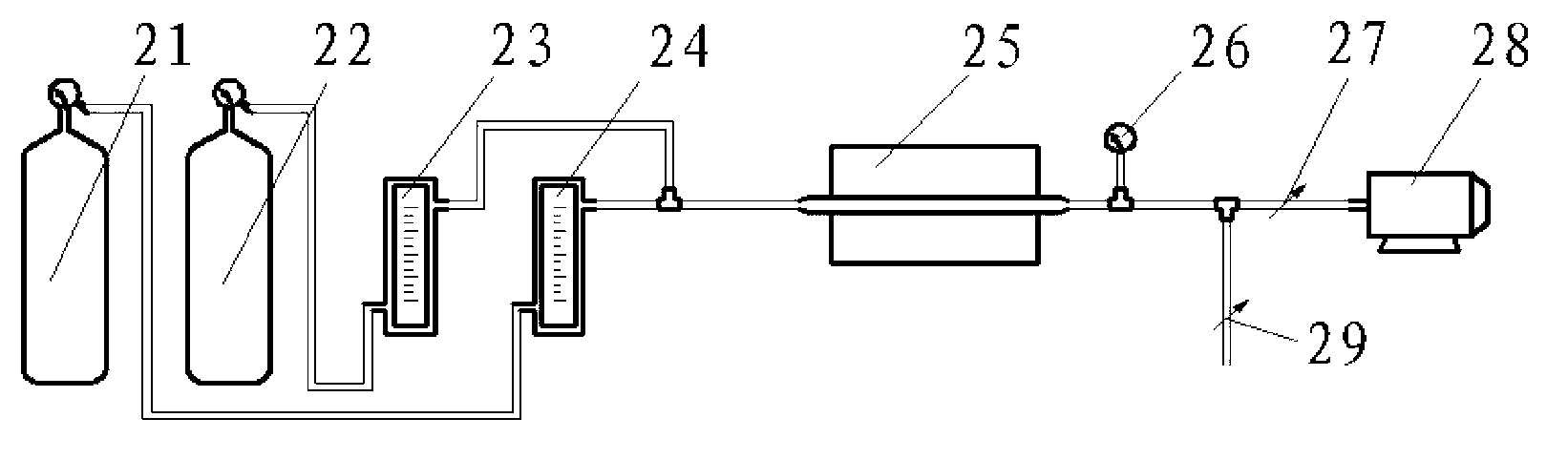

[0032] Then, the above Si substrate was placed in an oxygen plasma stripper to remove the PEO on the catalyst nanowires, and figure 2 The device uses the CVD method to pass the carbon source CH 4 And carrier gas and reducing gas Ar+H 2 To grow horizontal array carbon nanotubes, the specific steps are: ① place the Si sheet directly wri...

Embodiment 2

[0034] 0.01mol / L FeCl 3 Mix the ethanol solution with the PEO solution and stir evenly, suck 2ml of the above solution with the needle tube 13 and install it in the precision syringe pump 12 ( figure 1 ), using the principle of near-field electrospinning to directly write catalyst nanowires 14 with a diameter of 100nm on the Si substrate, the liquid supply rate of the precision syringe pump 12 used is 100μl / h, the voltage of the DC high-voltage power supply 11 is 4kV, and the distance between the needle and the substrate The spacing is 2.5mm. The experimental conditions for the subsequent removal of organic matter and the growth of horizontal array carbon nanotubes by CVD are the same as those in Example 1.

Embodiment 3

[0036] 0.001mol / L of FeCl 3 Mix the ethanol solution with the PEO solution and stir evenly, suck 2ml of the above solution with the needle tube 13 and install it in the precision syringe pump 12 ( figure 1 ), using the principle of near-field electrospinning to directly write catalyst nanowires 14 with a diameter of 200nm on the Si substrate, the liquid supply rate of the precision syringe pump 12 used is 100μl / h, the voltage of the DC high-voltage power supply 11 is 2.5kV, the needle and the substrate The distance between them is 2.5mm. The experimental conditions for the subsequent removal of organic matter and the growth of horizontal array carbon nanotubes by CVD are the same as those in Example 1.

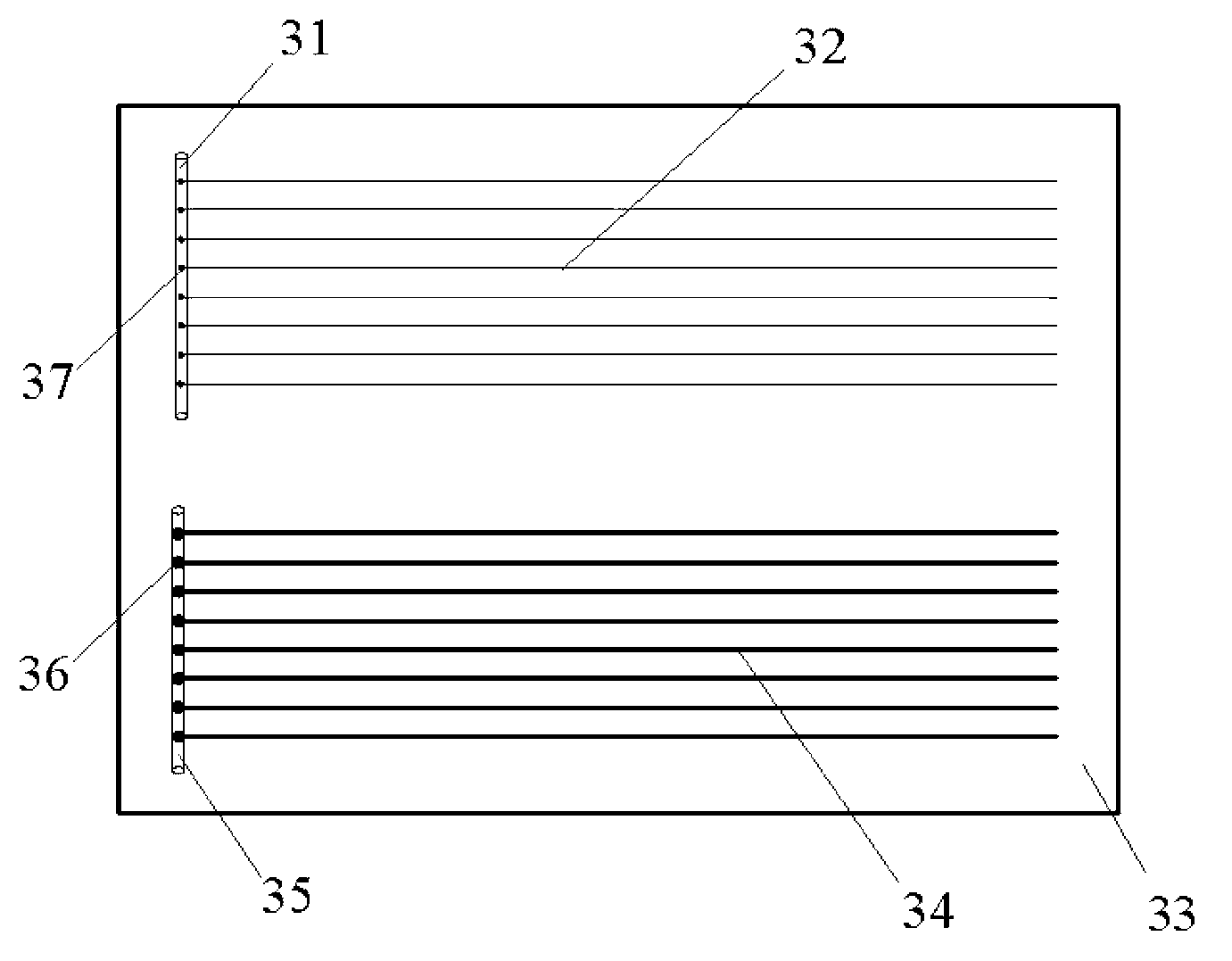

[0037] refer to image 3 , change the concentration of the catalyst ethanol solution to control the diameter of the carbon nanotube, the nanowire 31 adopts the FeCl of 0.001mol / L in embodiment 1 3 The solution is mixed with the PEO solution and directly written, and the org...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com