Preparation method of ternary layered carbide Ti2SC (titanium sulfur carbide) material

A ternary layered, carbide technology, applied in the direction of carbide, carbon oxide/sulfur carbide, etc., to achieve the effect of lowering synthesis temperature, simplifying process and reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

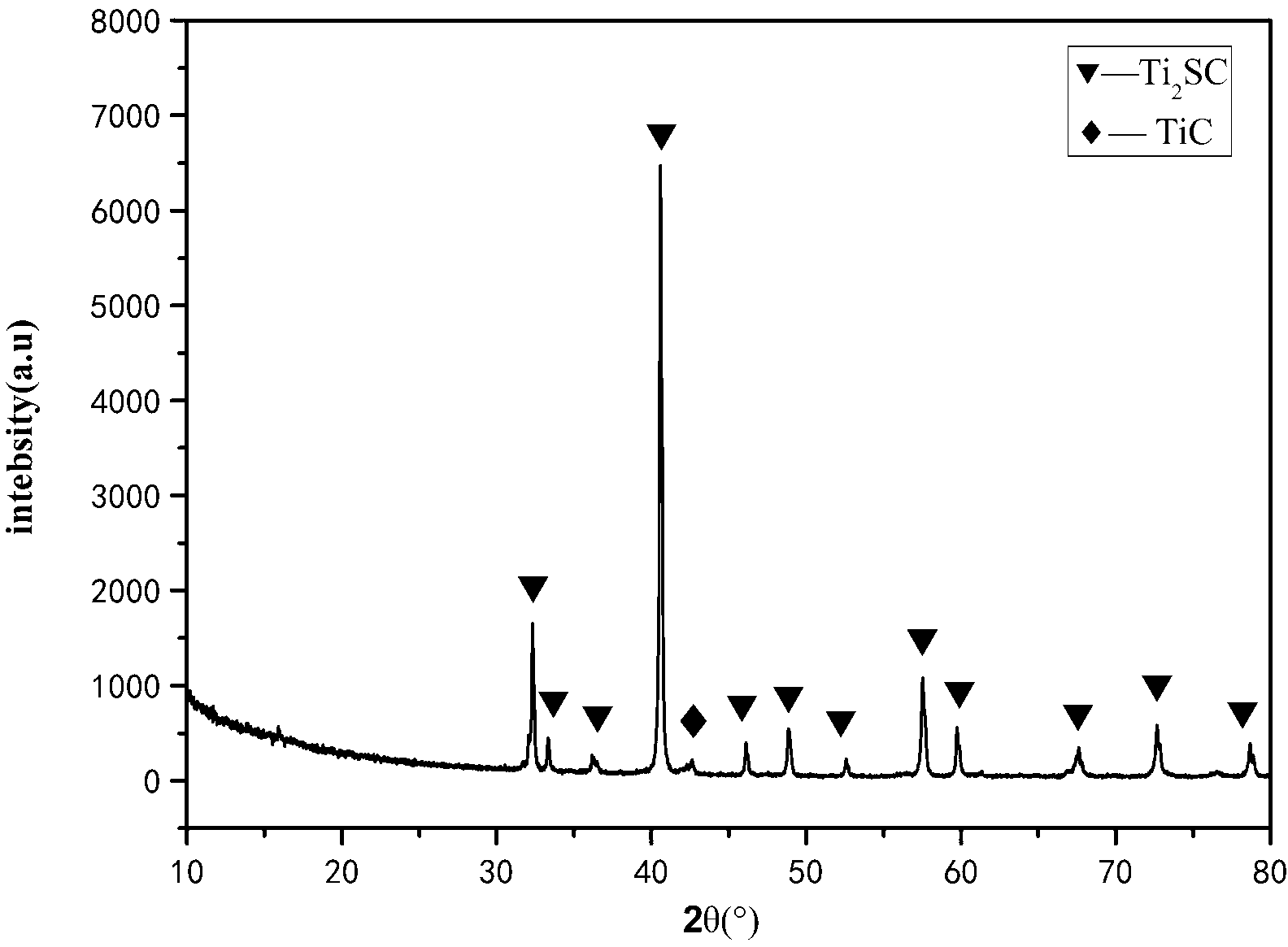

Embodiment 1

[0021] A kind of ternary layered carbide Ti 2 The preparation method of SC material, using Al as an auxiliary agent to prepare dense Ti by high temperature and high pressure synthesis method 2 SC material, its raw materials include Ti powder, S powder, C powder and Al powder, the molar ratio of the four raw materials is Ti:S:C:Al=2:1.2:1:0.1, the specific steps are as follows:

[0022] (1) Weighing: Weigh Ti powder, S powder, C powder and Al powder, and the molar ratio of the four raw materials is Ti:S:C:Al=2:1.2:1:0.1;

[0023] (2) Mix the weighed raw material powder in alcohol evenly, dry it, and put it into a steel mold for pre-pressing;

[0024] (3) Sintering: Put the formed sample into a pyrophyllite mold, then put it into a high temperature and high pressure furnace for sintering, the heating rate is 150°C / min, the sintering temperature is 1400°C, the pressure is 4GPa, hold for 1h, and then cool naturally with the furnace , the ternary layered carbide Ti can be obtaine...

Embodiment 2

[0028] A kind of ternary layered carbide Ti 2 The preparation method of SC material, using Al as an auxiliary agent to prepare dense Ti by high temperature and high pressure synthesis method 2 SC material, its raw materials include Ti powder, S powder, C powder and Al powder, the molar ratio of the four raw materials is Ti:S:C:Al=2:1.0:1:0.1, the specific steps are as follows:

[0029] (1) Weighing: Weigh Ti powder, S powder, C powder and Al powder. The molar ratio of the four raw materials is Ti:S:C:Al=2:1.0:1:0.1;

[0030](2) Mix the weighed raw material powder in alcohol evenly, dry it, and put it into a steel mold for pre-pressing;

[0031] (3) Sintering: Put the formed sample into a pyrophyllite mold, and then put it into a high-temperature and high-pressure furnace for sintering. The heating rate is 100°C / min, the sintering temperature is 1200°C, the pressure is 6GPa, and the temperature is kept for 10 minutes, and then naturally cooled with the furnace , the ternary l...

Embodiment 3

[0034] A kind of ternary layered carbide Ti 2 The preparation method of SC material, using Al as an auxiliary agent to prepare dense Ti by high temperature and high pressure synthesis method 2 SC material, its raw materials include Ti powder, S powder, C powder and Al powder, the molar ratio of the four raw materials is Ti:S:C:Al=2:1.1:1:0.2, and the specific steps are as follows:

[0035] (1) Weighing: Weigh Ti powder, S powder, C powder and Al powder, and the molar ratio of the four raw materials is Ti:S:C:Al=2:1.1:1:0.2;

[0036] (2) Mix the weighed raw material powder in alcohol evenly, dry it, and put it into a steel mold for pre-pressing;

[0037] (3) Sintering: Put the formed sample into a pyrophyllite mold, and then put it into a high-temperature and high-pressure furnace for sintering. The heating rate is 100°C / min, the sintering temperature is 1300°C, the pressure is 4GPa, and the temperature is kept for 30 minutes, and then naturally cooled with the furnace , the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com