Cold-end flexible cold chain structure of coaxial pulse tube refrigerator and manufacturing method

A pulse tube refrigerator, coaxial technology, applied in refrigerators, gas circulation refrigerators, refrigeration and liquefaction, etc., can solve the problems of adverse effects on the detection accuracy of cooled devices, reduced refrigerator efficiency, and damage to cooled devices. To achieve the effect of promoting conduction performance, reducing conduction distance and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and example the specific embodiment of the present invention is described in further detail:

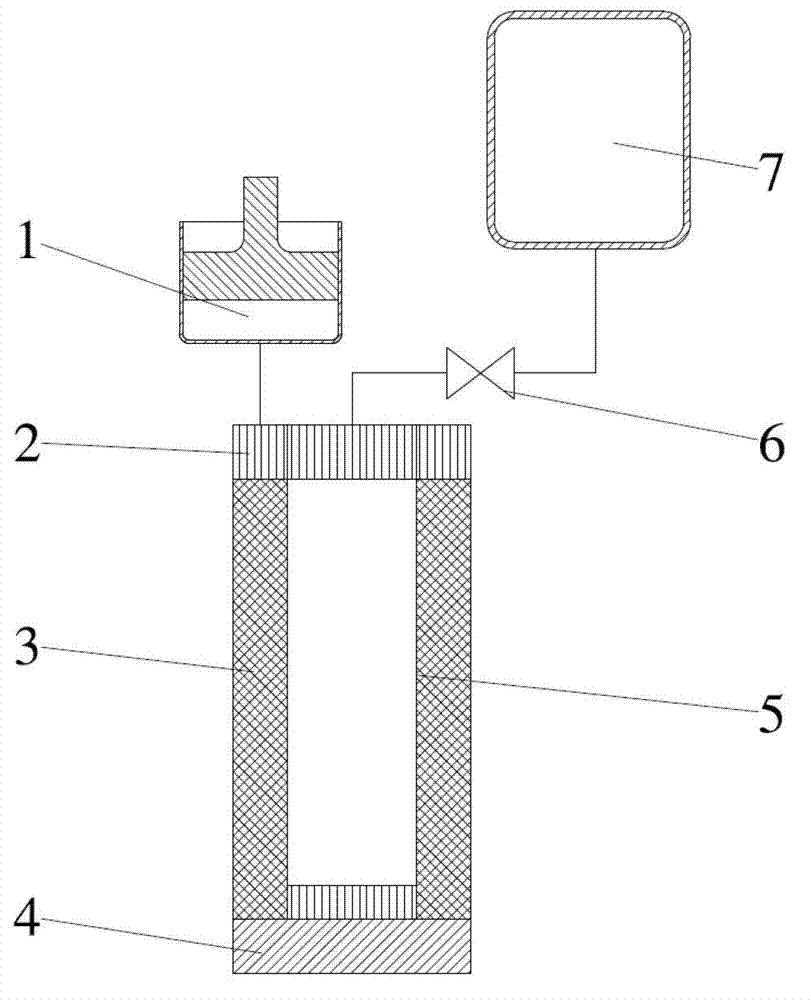

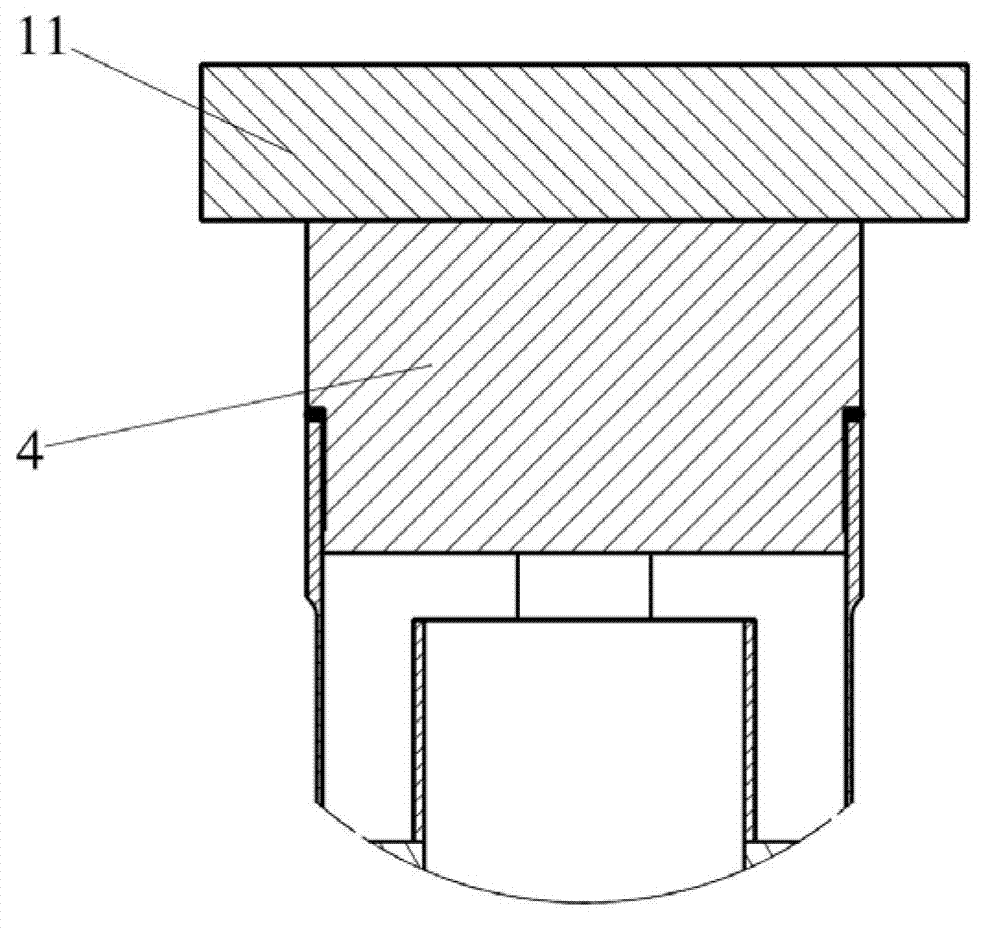

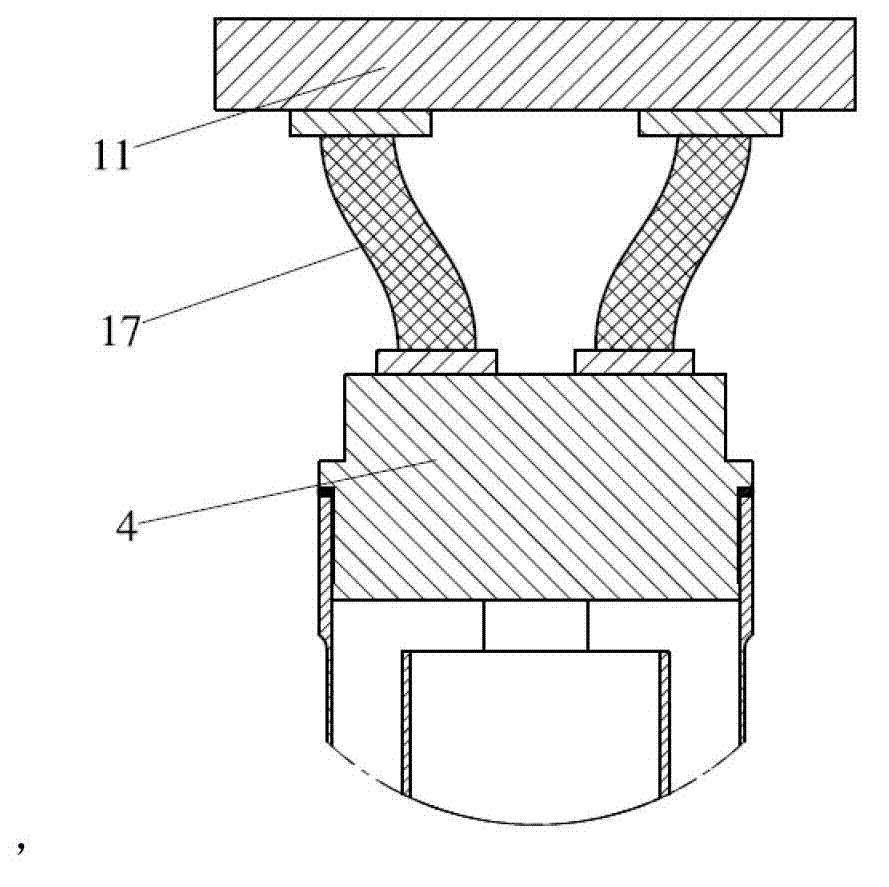

[0035] Figure 4 It is a schematic structural diagram of the invented flexible cold chain at the cold end of a coaxial pulse tube refrigerator, including a cooled device 11 , a cold head cap 8 , a spring 9 , and a cold head 4 .

[0036] Figure 6 A cross-sectional schematic diagram of the cold head of a coaxial pulse tube refrigerator.

[0037] The invented flexible cold chain structure of the cold end of the coaxial pulse tube refrigerator is composed of four parts: the cold head 4, the cold head cap 8, the spring 9, and the cooled device 11. It is characterized in that the cold chain of the coaxial pulse tube refrigerator The cold head cap 8 is used as a link between the head 4 and the cooled device 11. A spring 9 is installed in the counterbore 16 at the upper end of the cold head 4. Under the extrusion of the spring 9, the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com