Bolt type aluminium electrolytic capacitor with high reliability and high temperature resistance

An aluminum electrolytic capacitor, reliability technology, applied in the direction of capacitor electrodes, capacitor parts, etc., can solve problems such as not being able to meet the requirements, and achieve the effects of improving product reliability, improving heat dissipation performance, and reducing the conduction distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

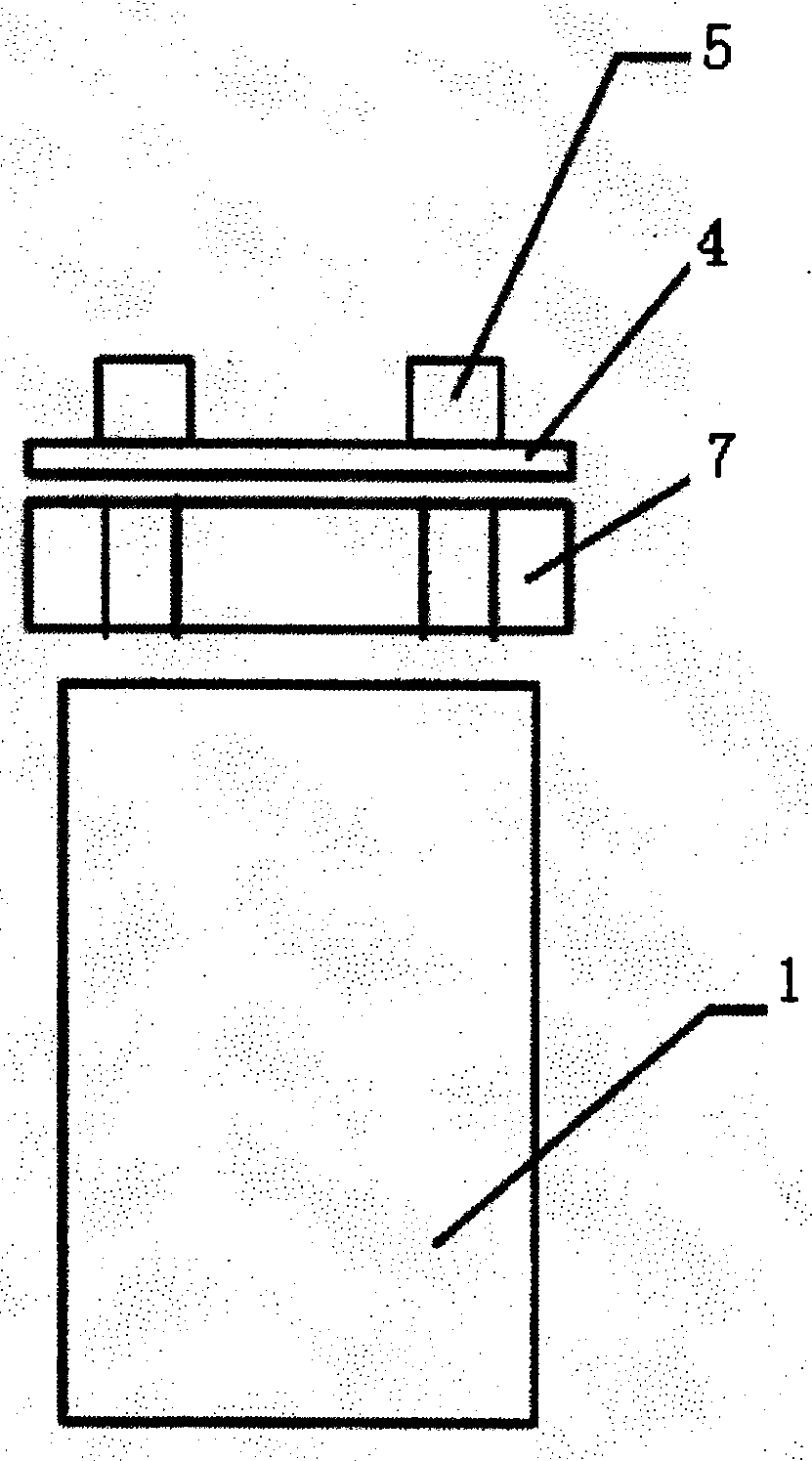

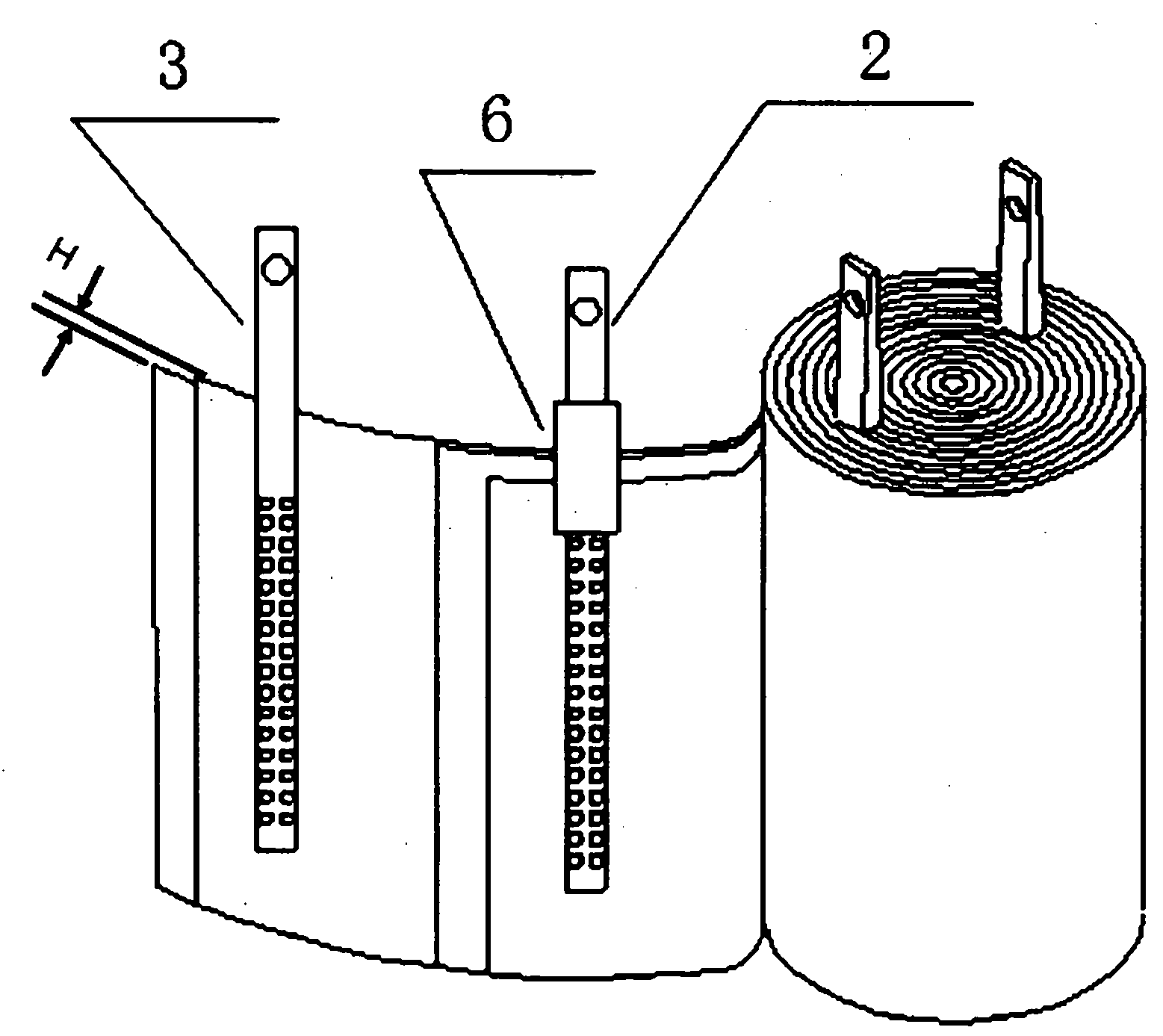

[0020] like figure 1 As shown, the present invention provides a bolt-type aluminum electrolytic capacitor, including a capacitor element 1, combined with figure 2 The capacitor element 1 is composed of the first electrolytic paper, the negative electrode foil with the negative conductive foil strip 3 riveted by cold pressure riveting or punching, the first electrolytic paper, the positive electrode foil with the positive conductive foil strip 2 riveted by cold pressure riveting or punching Layered and wound. The difference between the capacitor element 1 in the present invention and the existing capacitor elements is that the upper edge of the negative electrode foil extends upwards to expose the height of the upper edge of the first electrolytic paper to H, H≥0, so that the inside of the capacitor element 1 Heat can be conducted out through the negative electrode foil with the shortest distance. In order to conduct heat, a heat sink 7 is arranged above the capacitor elemen...

Embodiment 2

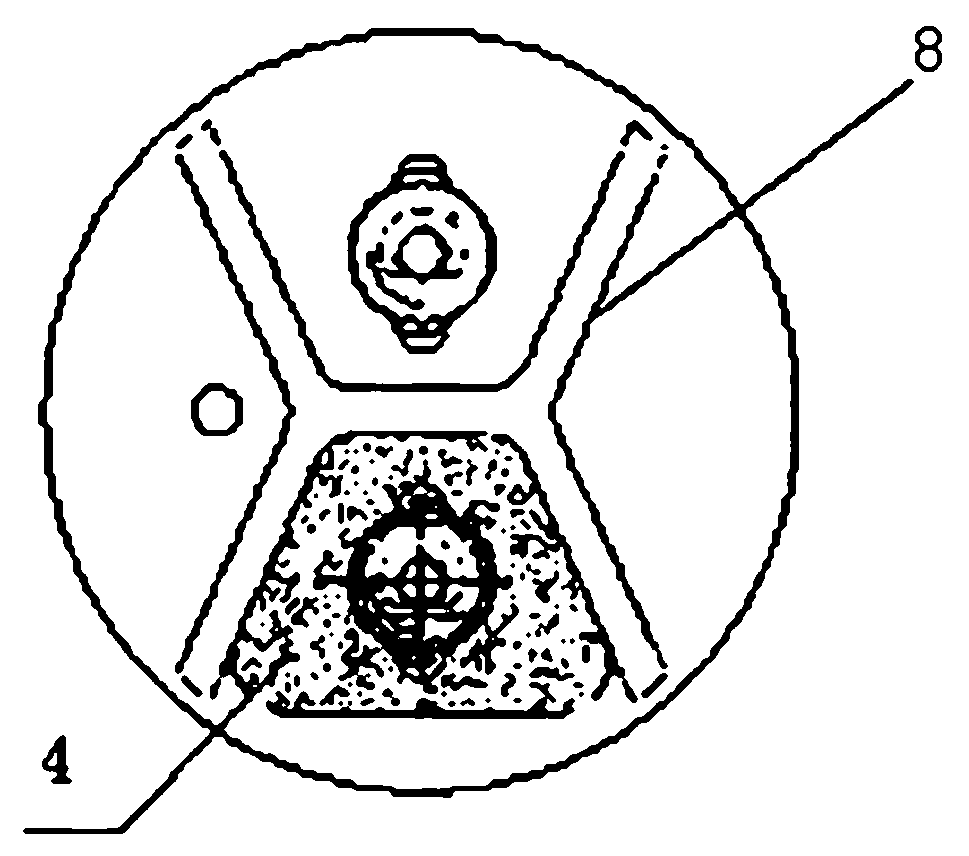

[0023] The difference between this embodiment and Embodiment 1 is that the cover plate 4 adopts a heat dissipation cover plate, and the heat dissipation cover plate can be made of aluminum. In order to ensure product performance, the purity of the aluminum material used in this example is 99.99%, and its structure is as follows: image 3 As shown, there is an H-shaped rib 8 at the bottom of the cover plate 4 . At this time, the structure of the heat sink 7 is as follows: Figure 4 As shown, a slot 9 is provided on it, and the reinforcing rib 8 is snapped into the slot 9, so that the heat sink 7 and the cover plate 4 can be assembled conveniently, which is convenient for production. There is a negative chaff hole 11 on the heat sink 7, so that all the negative chaff 3 can pass through the hole. There is also a positive foil grid 12 on the heat sink 7 for passing the positive foil 2 , and a hole in the positive foil grid 12 corresponds to one positive foil 2 . In order to incr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com