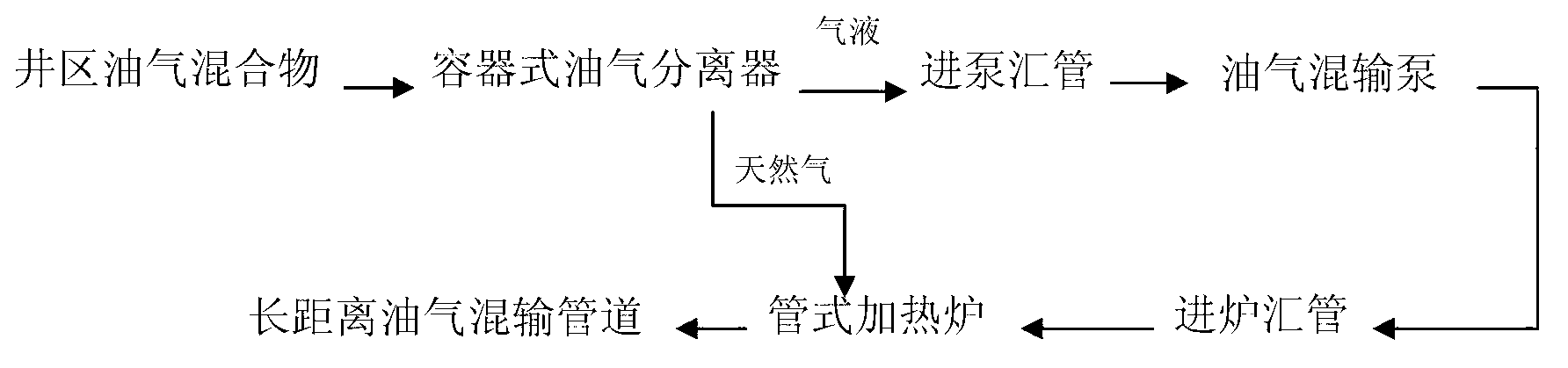

Pressurizing heating oil gas mixing transportation system and method

A technology of oil-gas mixed transportation and oil-gas mixed transportation pump, which is applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc. It can solve the problems of increasing the pressure energy loss of the furnace tube, affecting normal production, and reducing the service life. Effects of project investment and operation energy consumption, reduction of total gas-liquid transport volume, and reduction of gas flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

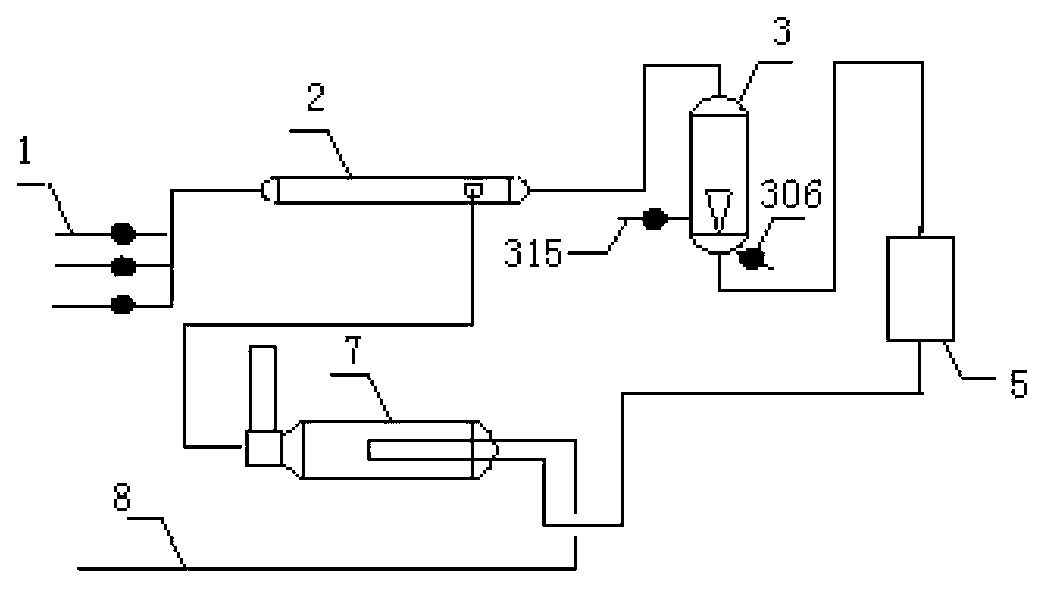

[0054] Implementation Mode 1: Oil and gas mixed transportation process suitable for operation of one mixed transportation pump

[0055] see figure 2 As shown, a pressurized heating oil-gas mixed transportation system provided by the present invention includes an intake valve group 1, a fuel gas separator 2, a multi-phase vibration desander 3, and an oil-gas mixed transportation pump 5 connected sequentially through pipelines. , a tubular heating furnace 7 and a long-distance oil-gas mixed transportation pipeline 8. The main feature of this system is that on the basis of the existing technology, a new type of multi-phase vibration desander 3 is added between the fuel gas separator 2 and the oil-gas mixing pump 5, and the multi-phase vibration desander 3 The inlet of the fuel gas separator is connected to the gas-liquid outlet of the fuel gas separator 2, and the gas-liquid outlet of the multi-phase vibration desander 3 is connected to the oil-gas mixed delivery pump 5 through...

Embodiment approach 2

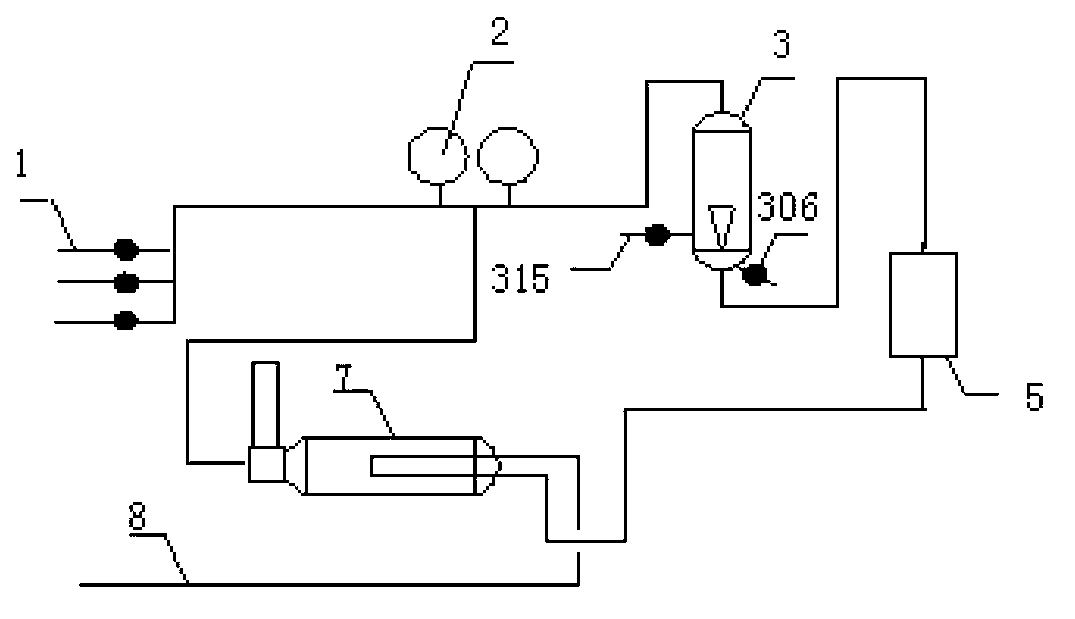

[0102] Implementation mode 2: Oil and gas mixed transportation process suitable for parallel operation of more than two mixed transportation pumps

[0103] Another pressurized heating oil-gas mixed transportation system provided by the present invention, see Figure 10 As shown, it includes the intake valve group 1, the fuel gas separator 2, the multi-phase vibration desander 3, the inlet uniform flow device 4 of the multi-phase mixed pump group connected in sequence through the pipeline, and multiple oil and gas mixed transport units connected in parallel. Pump 5, tubular heating furnace 7 and long-distance oil and gas mixed transportation pipeline 8. The main feature of this system is that on the basis of the first embodiment, a multi-phase mixed-transport pump set inlet uniform flow device 4 is added at the inlet of the multi-phase vibration desander 3 and multiple parallel-operated oil-gas mixed transport pumps 5 . The inlet uniform flow device 4 of the multi-phase mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com