Method for rapidly producing biodiesel from kitchen garbage and produced biodiesel

A technology of biodiesel and kitchen waste, applied in the direction of biofuel, fat production, fatty acid production, etc., can solve the problems of difficult large-scale application, long reaction time, low reaction rate, etc., and achieve the goal of reducing high temperature and high pressure and production energy consumption Requirements, product post-processing is simple, the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

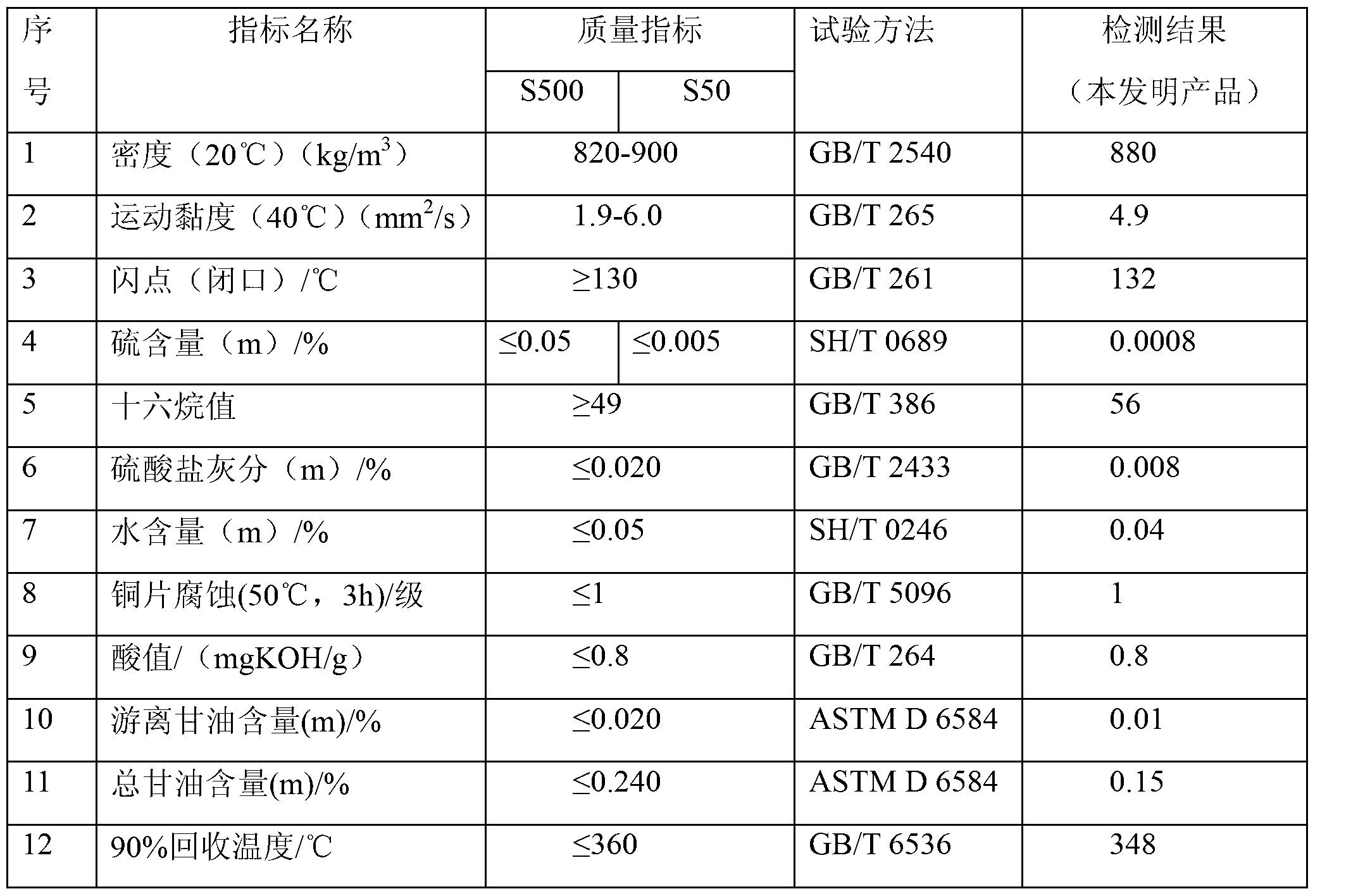

Embodiment 1

[0030] First, pre-treat the received food waste, sorting (removing solid impurities such as bones and gravel), crushing (breaking up the fat and meat in the food waste), vacuum dehydration (controlling the temperature at 100-150 ℃ , the vacuum degree is 0-5Kpa), and hogwash oil is obtained after pretreatment. Methanol and hogwash oil were weighed according to the mass ratio of methanol and hogwash oil as 220:100, and the catalyst was weighed according to the mass percentage of the alkali catalyst KOH accounting for 1% of the oil. After the catalyst is dissolved in methanol, it is mixed with hogwash oil and put into a high-pressure reactor, stirred and heated to 180°C, and the reaction pressure is controlled within the range of 1-10MPa. Stop the reaction after reacting for 12 minutes, cool the reaction kettle to room temperature, and recover excess methanol by distillation under reduced pressure. The upper layer product was analyzed by gas chromatography, and the conversion ra...

Embodiment 2

[0032] First, the received food waste is pretreated, sorted (removing solid impurities such as bones and gravel), crushing (breaking up the fat in the food waste), vacuum dehydration (temperature control 100-150°C, Vacuum degree is 0-5Kpa), hogwash oil is obtained after pretreatment. According to the mass ratio of methanol and hogwash oil is 80:100 to take methanol, hogwash oil, according to the alkali catalyst KNO 3 / Al 2 o 3 Accounting for 3% by mass of oil, the catalyst was weighed. Dissolve the catalyst in methanol, then mix it with hogwash oil and add it to the autoclave, pump carbon dioxide into the autoclave, adjust the molar ratio of carbon dioxide and methanol to 1:1, stir and heat, control the temperature at 80°C, and control the reaction pressure at 1 -10MPa range. Stop the reaction after reacting for 12 minutes, cool the reaction kettle to room temperature, and recover excess methanol by distillation under reduced pressure. The upper layer product was analyzed...

Embodiment 3

[0034]First, the received food waste is pretreated, sorted (removing solid impurities such as bones and gravel), crushing (breaking up the fat in the food waste), vacuum dehydration (temperature control 100-150°C, Vacuum degree is 0-5Kpa), hogwash oil is obtained after pretreatment. According to the mass ratio of methanol and hogwash oil is 60:100 to take methanol, hogwash oil, according to the solid acid catalyst SO 4 2- / TiO 2 The mass percentage of oil is 5% and the catalyst is weighed. Dissolve the catalyst in methanol, then mix it with hogwash oil and add it to the autoclave, then pump acetic acid into the autoclave, adjust the molar ratio of acetic acid to methanol to 8:1, stir and heat, control the temperature at 200°C, and control the reaction pressure In the range of 1-10MPa. After 20 minutes of reaction, the reaction was stopped, excess acetic acid was recovered by rotary evaporation, the reaction kettle was cooled to room temperature, and excess methanol was rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com