Microemulsion-solvothermal technique of orthorhombic InOOH

An orthorhombic and solvothermal technology, which is applied in chemical instruments and methods, inorganic chemistry, gallium/indium/thallium compounds, etc., can solve the problems of large equipment investment, high energy consumption, and demanding equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

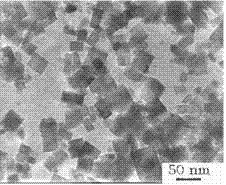

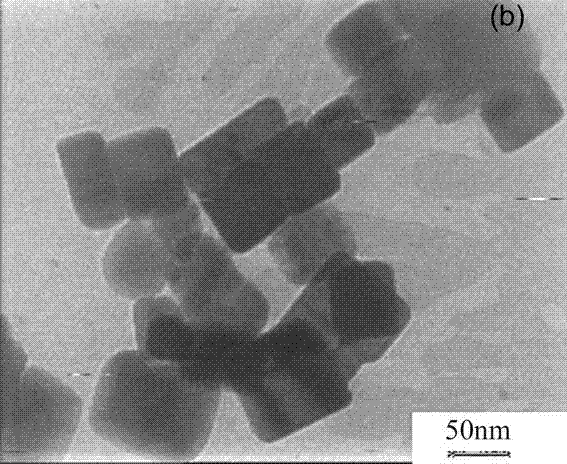

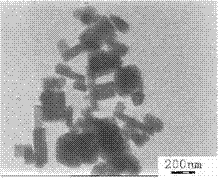

Image

Examples

Embodiment 1

[0039] (1). Preparation of microemulsion

[0040] a. The microemulsion consists of 18ml n-hexane and 4ml n-pentanol, and 8ml octadec-cis-9-enoic acid is added to the beaker in turn under magnetic stirring, b. Then 2ml 0.5mol / l indium salt solution is added to the beaker In, dropwise add 3.0ml of sodium hydroxide solution whose mass percentage concentration is 15%, continue to stir for 15 minutes, adjust pH value to be 8, obtain emulsion;

[0041] (2). Solvothermal preparation of orthorhombic InOOH

[0042] a. Move the emulsion to a polytetrafluoroethylene container, then seal the tetrafluoroethylene container in a stainless steel autoclave, heat and react at 180°C for 20 hours, and then cool to room temperature,

[0043] b. The product is centrifuged and washed, and the precipitate is dried and ground to obtain one-dimensional orthorhombic InOOH.

Embodiment 2

[0045] (1). Preparation of microemulsion

[0046] a. The microemulsion consists of 20ml of n-hexane and 5ml of n-pentanol, and 9ml of octadec-cis-9-enoic acid was added to the beaker in turn under magnetic stirring, b. Then 1.5ml of 0.8mol / l indium salt solution was added In the beaker, add 2.5ml of sodium hydroxide solution with a mass percentage concentration of 17% dropwise, continue stirring for 15 minutes, and adjust the pH value to 9 to obtain an emulsion;

[0047] (2). Solvothermal preparation of orthorhombic InOOH

[0048] a. Move the emulsion to a polytetrafluoroethylene container, then seal the tetrafluoroethylene container in a stainless steel autoclave, heat and react at 190°C for 19 hours, and then cool to room temperature,

[0049] b. The product is centrifuged and washed, and the precipitate is dried and ground to obtain one-dimensional orthorhombic InOOH.

Embodiment 3

[0051] (1). Preparation of microemulsion

[0052] a. The microemulsion consists of 22ml of n-hexane and 6ml of n-pentanol, and 12ml of octadeca-cis-9-enoic acid is added to the beaker in turn under magnetic stirring, b. Then 1.2ml of 0.7mol / l indium salt solution is added In the beaker, add 2.0 ml of sodium hydroxide solution with a mass percentage concentration of 19% dropwise, continue stirring for 15 minutes, and adjust the pH value to 10 to obtain an emulsion;

[0053] (2). Solvothermal preparation of orthorhombic InOOH

[0054] a. Move the emulsion to a polytetrafluoroethylene container, then seal the tetrafluoroethylene container in a stainless steel autoclave, heat and react at 200 ° C for 18 hours, and then cool to room temperature,

[0055] b. The product is centrifuged and washed, and the precipitate is dried and ground to obtain one-dimensional orthorhombic InOOH.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com