Method for making instant chicken sauce slices through microwave spouted freeze-drying

A technology of microwave spraying and chicken juice, which is applied in the direction of drying solid materials, drying, food preparation, etc., can solve the problems of product comprehensive quality deterioration, drying quality decline, uneven heating, etc., and achieve good instant effect , Drying quality decline, fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

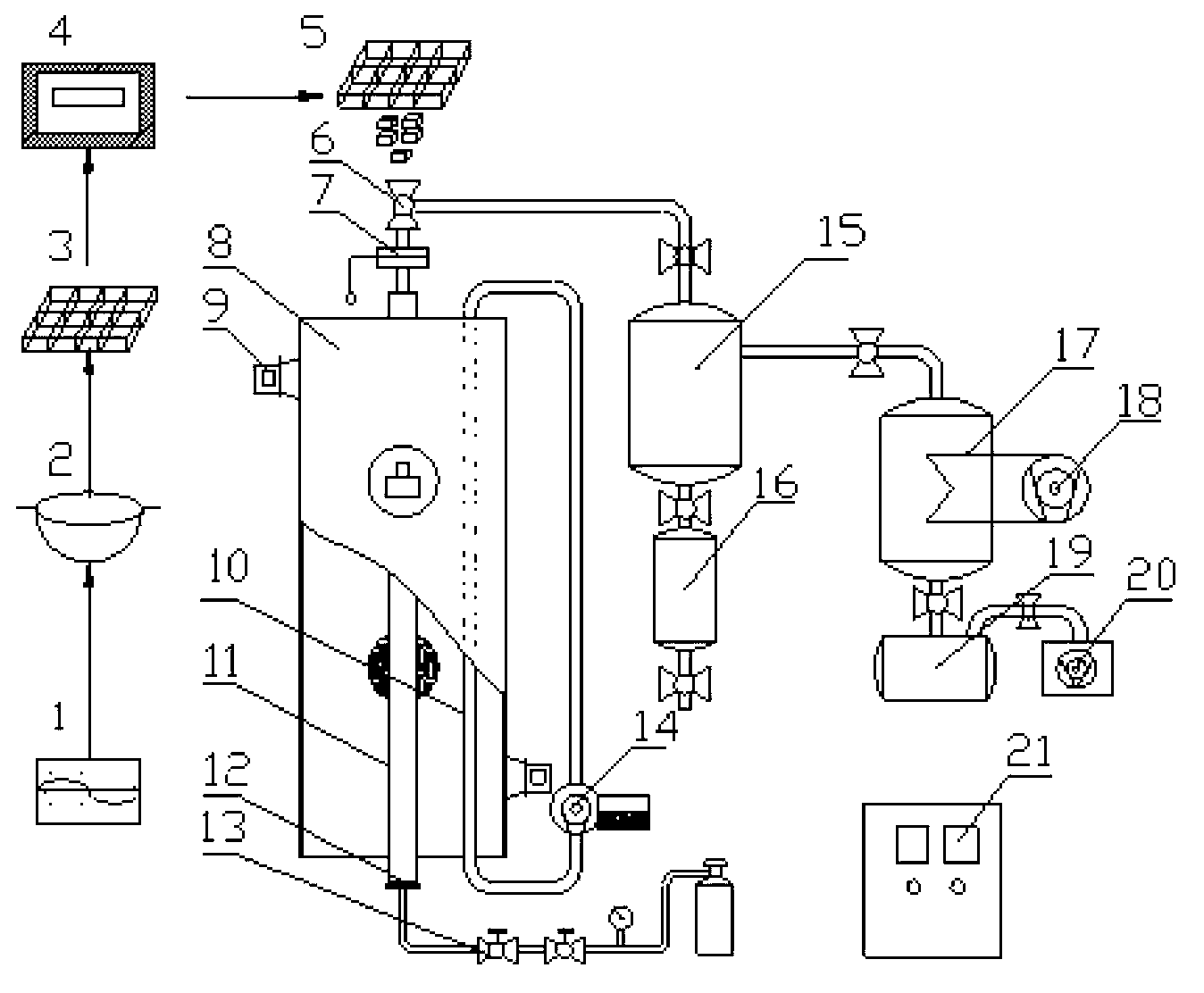

Image

Examples

Embodiment 1

[0034] Embodiment 1, the method that microwave pulse spray freeze-drying makes loose type instant chicken juice piece

[0035] Weigh 100kg of ingredients according to the weight ratio of modified starch, cyclodextrin, maltodextrin, and clean water in a ratio of 1:2:3:19, including: 4kg of modified starch, 8kg of cyclodextrin, 12kg of clean water, 76kg of water. Add the weighed modified starch, cyclodextrin and maltodextrin into the mixer in sequence and mix evenly. Pour the weighed clean water into the cooker, heat to 80°C, pour the above three mixtures into the cooker, and keep stirring until there is no agglomeration, keep the temperature at 70°C, and then mix according to the boil Add 100kg of chicken juice in a weight ratio of 1:1 between ingredients and chicken juice, and keep stirring. At this time, the cooker is no longer heated until it is uniform. When the temperature of the soup in the cooker is lower than 40°C, take it out and put it into the mold, and scrape ...

Embodiment 2

[0036] Embodiment 2, the method for making compact instant chicken juice cubes by microwave pulse spray freeze-drying

[0037] According to the modified starch, cyclodextrin, maltodextrin and clean water, weigh 100kg of ingredients according to the weight ratio of 1:4:5:10, including: 5kg of modified starch, 20kg of cyclodextrin, 25kg of maltodextrin, 50kg of clean water. Add the weighed modified starch, cyclodextrin and maltodextrin into the mixer in sequence and mix evenly. Pour the weighed clean water into the cooker, heat to 80°C, pour the above three mixtures into the cooker, and keep stirring until there are no lumps, keep the temperature at 80°C, and then mix according to the cooking method Add 150kg of chicken broth in a weight ratio of 1:1.5 between ingredients and chicken broth, stop heating the cooker, and keep stirring until uniform. When the temperature of the soup in the cooker is lower than 50°C, take it into the mold and scrape it flat, put the soup with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com