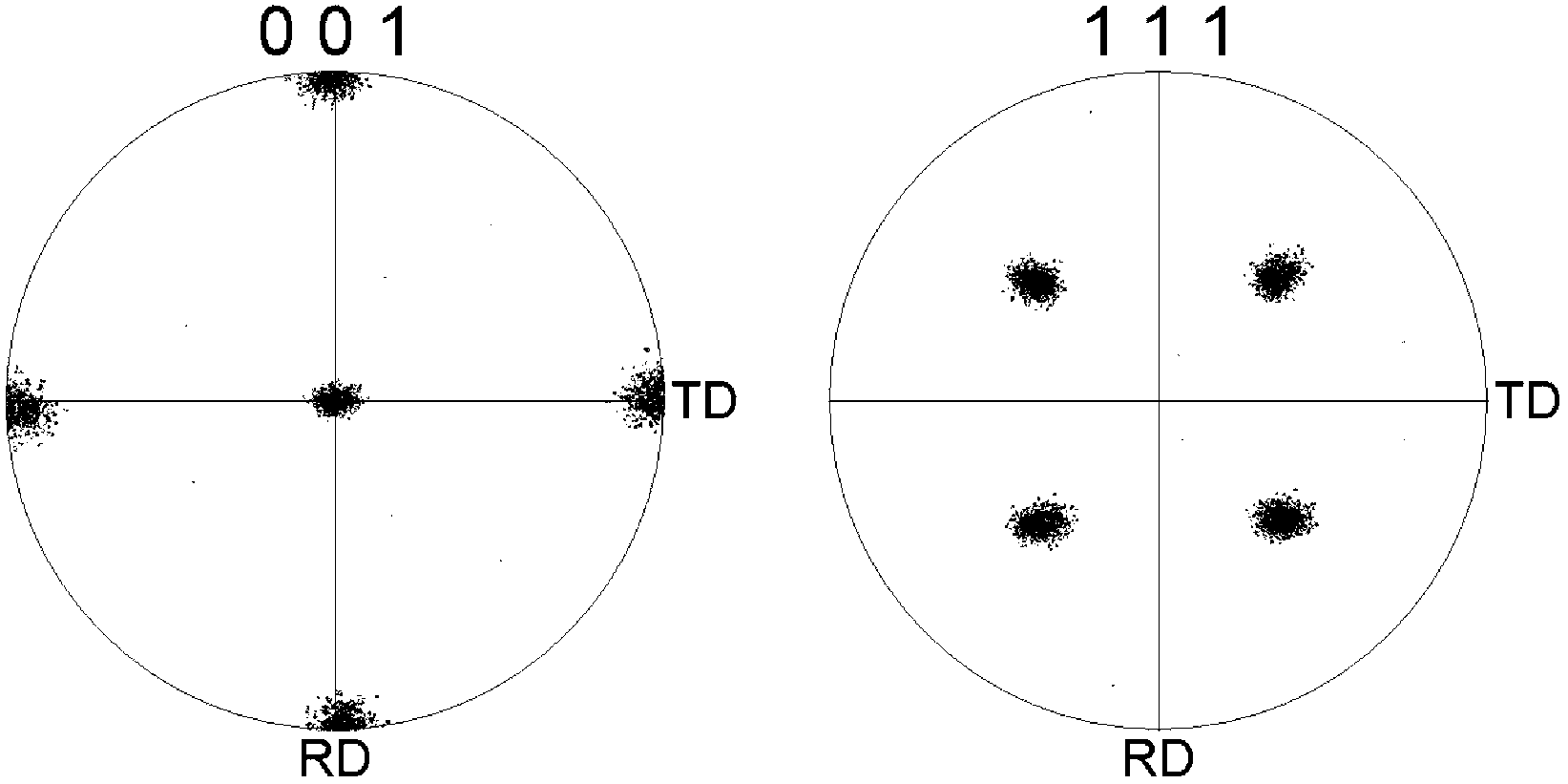

Method for preparing strong-cube-texture low-magnetism compound Ni-W alloy base bands

A strong cubic texture and composite technology, applied in metal rolling, usage of superconducting elements, superconducting devices, etc., can solve problems such as difficult to realize large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) The Ni block with a purity of 99.95% and a W block with a purity of 99.99% are proportioned according to the molar percentage of W as 5% and 12% respectively; these two raw materials with different proportions are placed in an intermediate frequency vacuum Two kinds of ingots with low W content and high W content are obtained by smelting in an induction furnace; two Ni-W alloy billets with the same size and thickness of 12mm are obtained by hot forging and wire cutting;

[0021] (2) Grind and polish the contact surfaces of the two alloy billets to ensure that the surface roughness is less than 0.005mm, and use ethanol or acetone for ultrasonic cleaning; stack the two alloy billets and clamp them with a clamp to make the polished The surfaces are tightly attached together; one end of the billet is machined into a cone shape to facilitate biting during rolling, and the end of the two billets processed into a cone shape is welded and fixed by argon arc welding to obtain th...

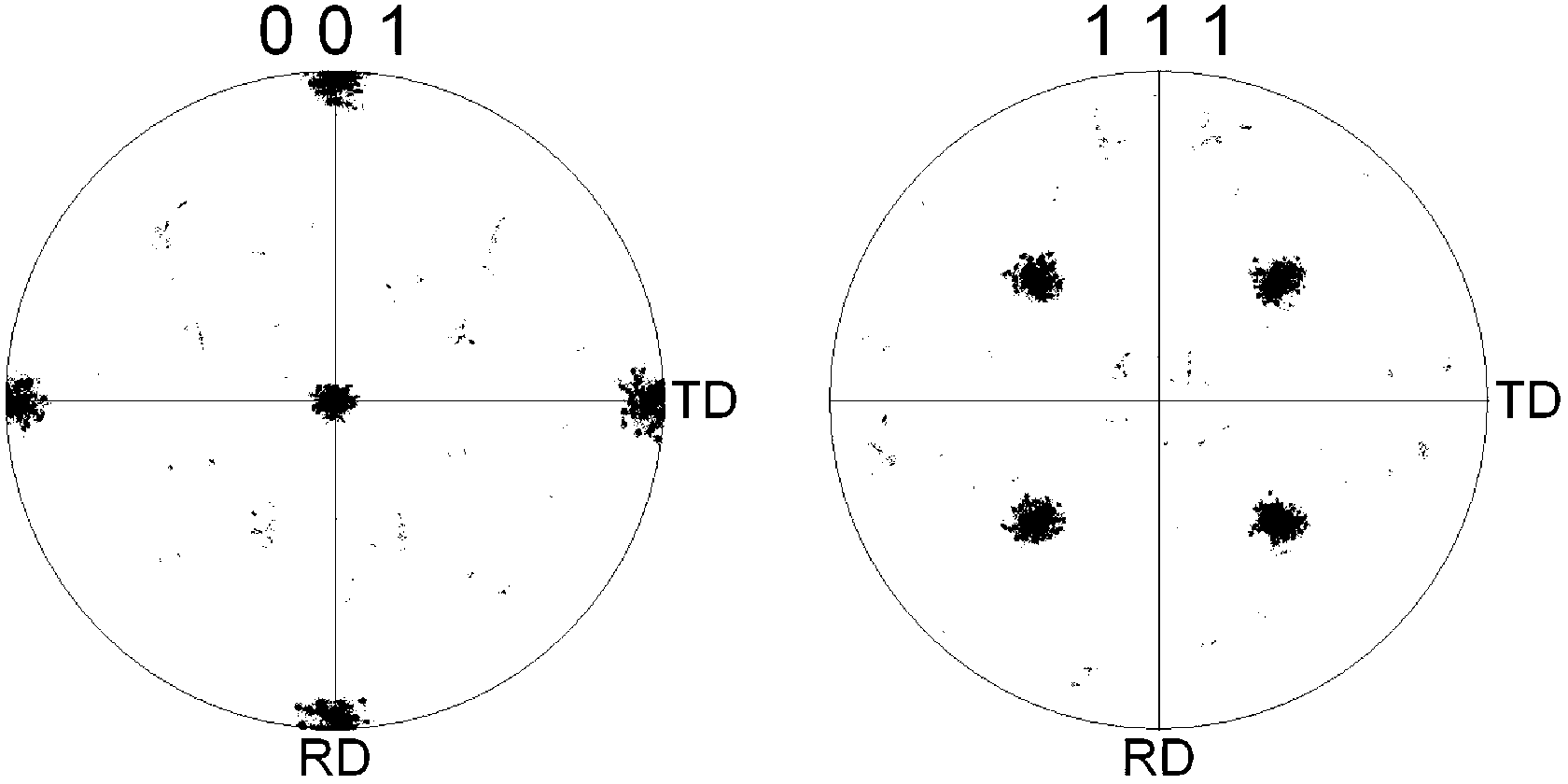

Embodiment 2

[0028] (1) The Ni block with a purity of 99.95% and the W block with a purity of 99.99% are proportioned according to the molar percentage of W as 7% and 9% respectively; these two raw materials with different proportions are placed in an intermediate frequency vacuum Two ingots with low W content and high W content are obtained by smelting in an induction furnace; two Ni-W alloy billets with the same size and thickness of 10mm are obtained by hot forging and wire cutting;

[0029] (2) Grind and polish the contact surfaces of the two alloy billets to ensure that the surface roughness is less than 0.005mm, and use ethanol or acetone for ultrasonic cleaning; stack the two alloy billets and clamp them with a clamp to make the polished The surfaces are tightly attached together; one end of the billet is machined into a cone shape to facilitate biting during rolling, and the end of the two billets processed into a cone shape is welded and fixed by argon arc welding to obtain the AB str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com