On-line machine tool equipment utilization state monitoring method and device based on power information

A technology of machine tool status and power information, applied in the fields of communication and machinery manufacturing, can solve the problems of lack of production and processing information and feedback control methods of the upper and lower layers, accuracy, real-time performance cannot be guaranteed, processing information statistical time lag, etc. Achieve the effect of improving the utilization rate of machine tools, facilitating remote monitoring and management, and improving work enthusiasm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

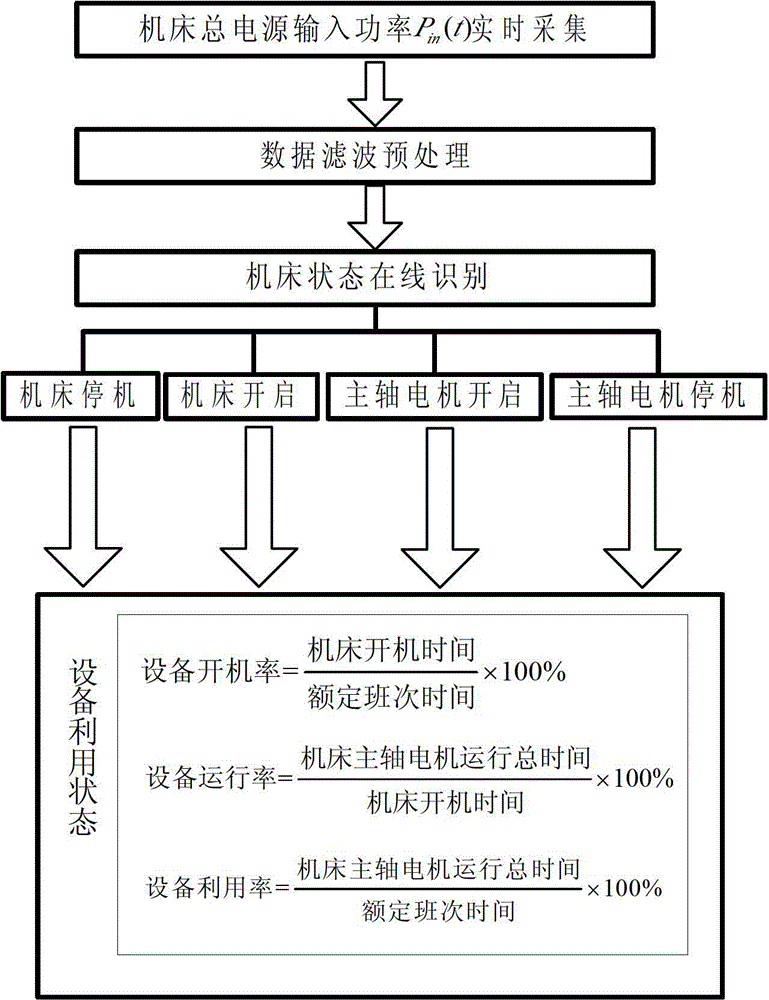

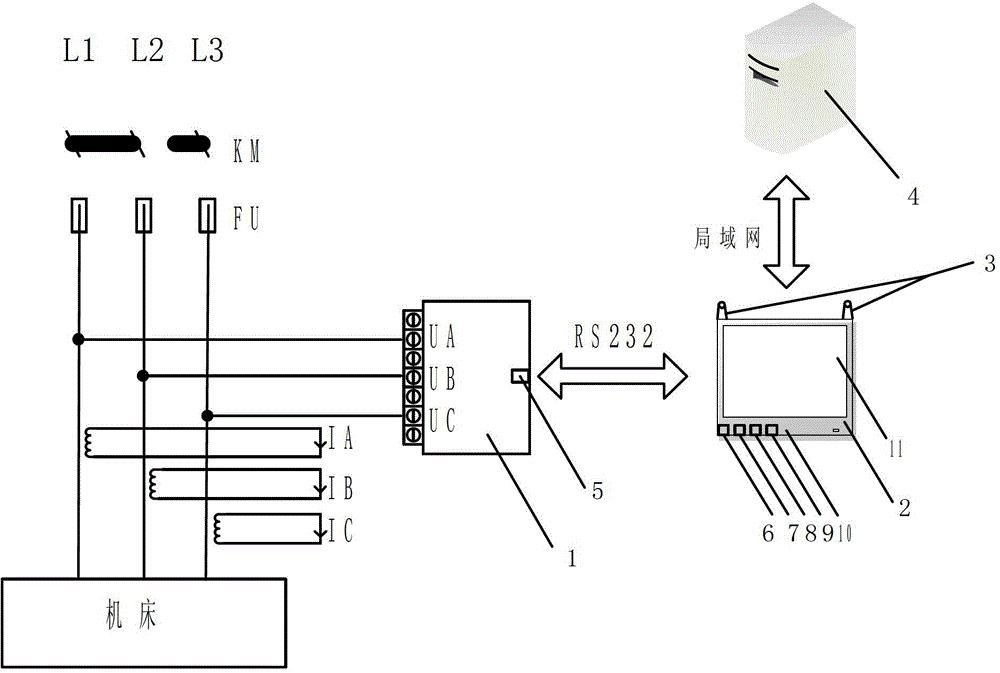

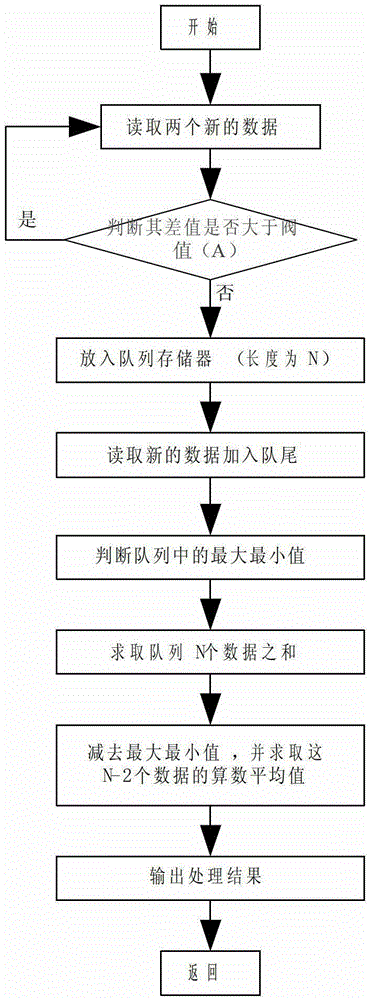

[0059] The device of the present invention was used to carry out relevant application experiments on a CA620 common lathe in a certain workshop, and the equipment utilization status of the machine tool operation process during the entire shift time (note: the rated shift time of the workshop is 8 hours) was monitored online. Install a power sensor at the main power supply of the machine tool, set the data sampling period to 20ms, collect the input power of the machine tool in real time, and perform low-pass filtering processing to convert the analog signal into a digital signal; fixedly install an information terminal at the machine tool bed, through the serial port line Connect with the power sensor, receive the power signal transmitted by the power sensor in real time, perform digital filtering of the power signal, identify the operating status of the machine tool online, calculate and count information such as the machine tool equipment startup rate, equipment operation rate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com