Method for preparing dense enhancement type ceramic membrane based on micro-arc oxidizing and laser remelting

A technology of laser remelting and micro-arc oxidation, which is applied in anodic oxidation, coating, surface reaction electrolytic coating, etc., can solve the problem of not having low energy consumption and high performance of the film layer at the same time, so as to reduce processing time and energy consumption, Improve hardness, anti-corrosion and wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

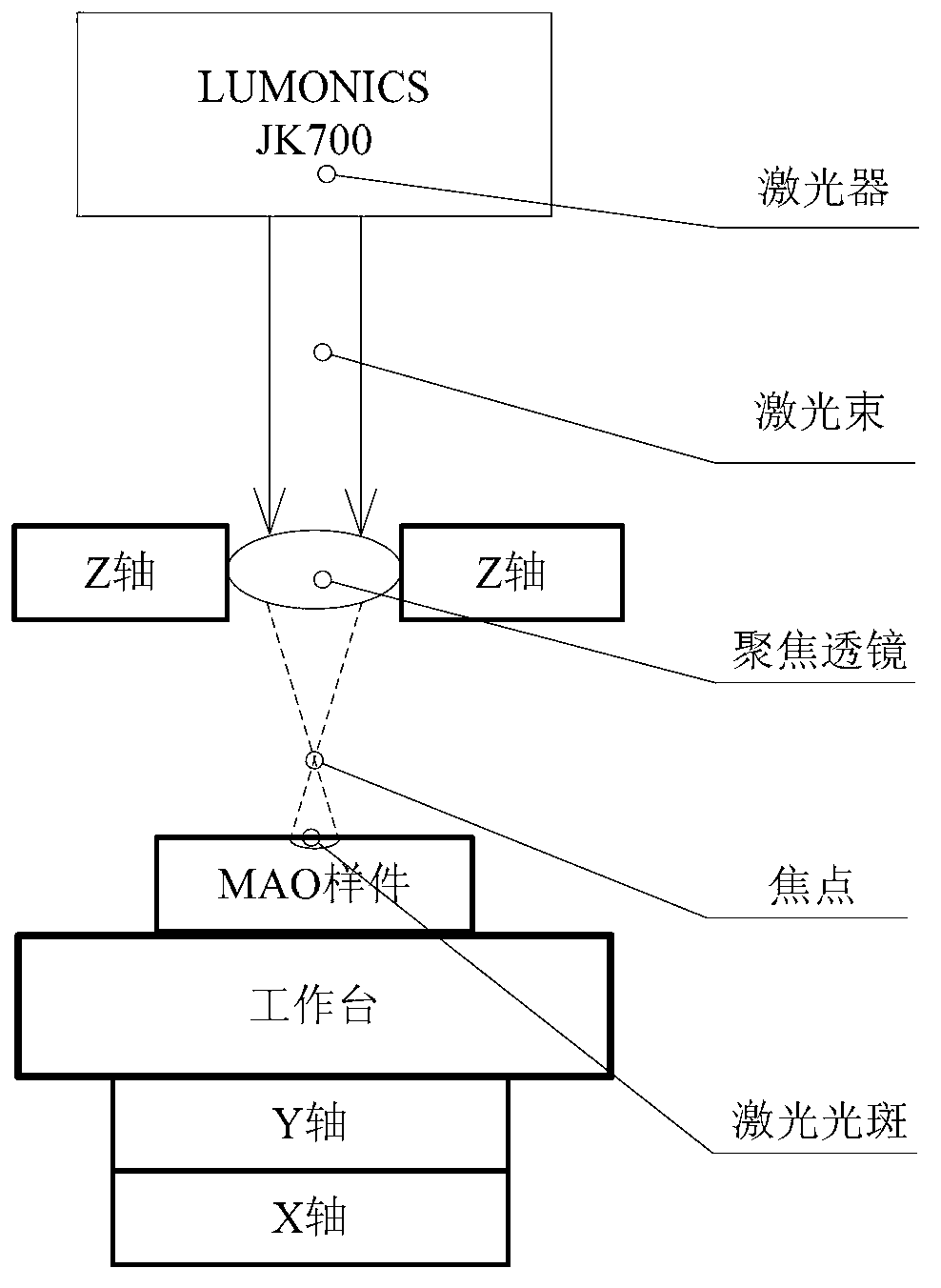

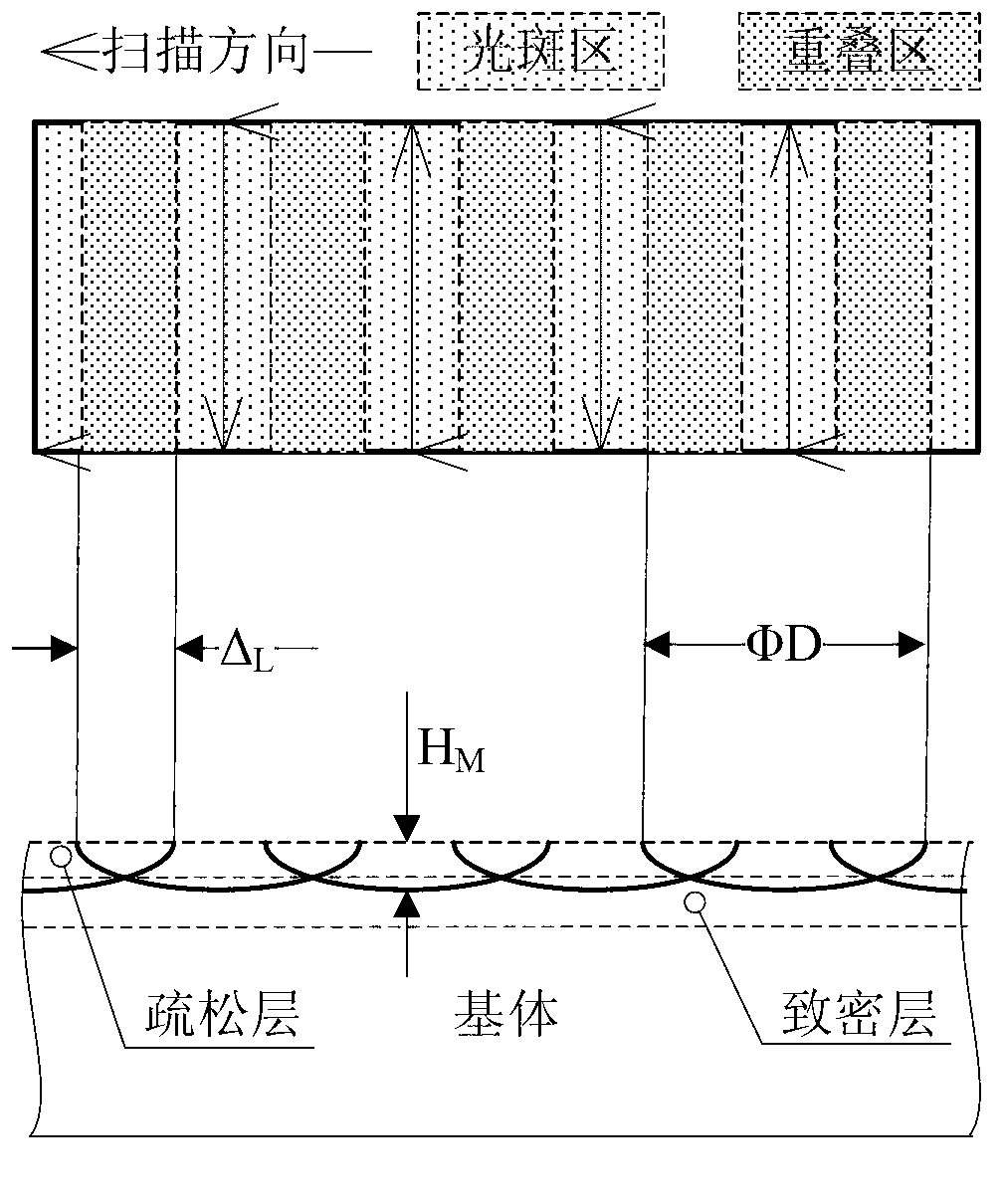

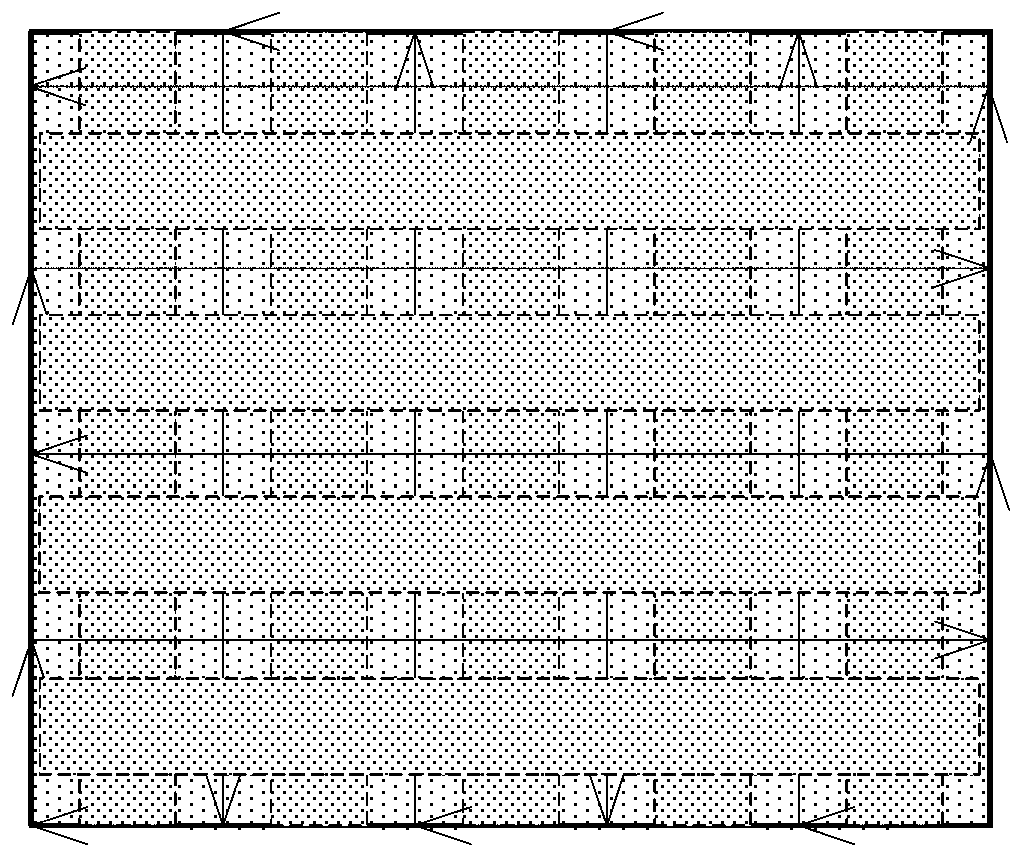

[0017] Specific implementation mode one: combine Figure 1 ~ Figure 4 In this embodiment, a method for preparing a denseness-enhanced ceramic film layer based on micro-arc oxidation and laser remelting is carried out according to the following steps:

[0018] 1. Pretreatment of matrix material: choose 300 # Sandpaper ~ 2000 # Use two or more types of sandpaper in the sandpaper to grind the base material step by step, then wash the ground base material with water for 3-5 minutes, and then wash it with NaOH solution with a concentration of 20g / L-100g / L for 5min- After 10 minutes, put the base material after alkali washing into acetone or absolute ethanol, clean it with ultrasonic waves with a frequency of 24KHz-40KHz for 1min-3min, and finally wash it in deionized water for 2min-5min, then air-dry or air-dry to obtain pretreatment After the base material;

[0019] 2. Preparation of working solution: Add the main film-forming agent, pH regulator, stabilizer, colorant and color...

specific Embodiment approach 2

[0038] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the base material in step 1 is magnesium, aluminum, titanium, magnesium alloy, aluminum alloy or titanium alloy. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0039] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the main film-forming agent Na described in step two 2 SiO 3 , NaAlO 2 、Na 3 PO 4 and (NaPO 3 ) 6 One or a mixture of several of them; the pH regulator described in step two is KOH or NaOH; the stabilizer described in step two is KF or NaF; the colorant described in step two is tungstic acid Sodium, ammonium metavanadate, copper sulfate or H 3 BO 3 ; The coloring leveling agent described in step 2 is ethylenediaminetetraacetic acid disodium (ETDA-2Na). Others are the same as in the first or second embodiment.

[0040] When the main film-forming agent described in this embodiment is a mixture, the components are mixed in any proportion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com