Method for extracting copper by utilizing waste browning liquid

A technology of browning liquid and solution, which is used in the improvement of process efficiency, photography technology, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

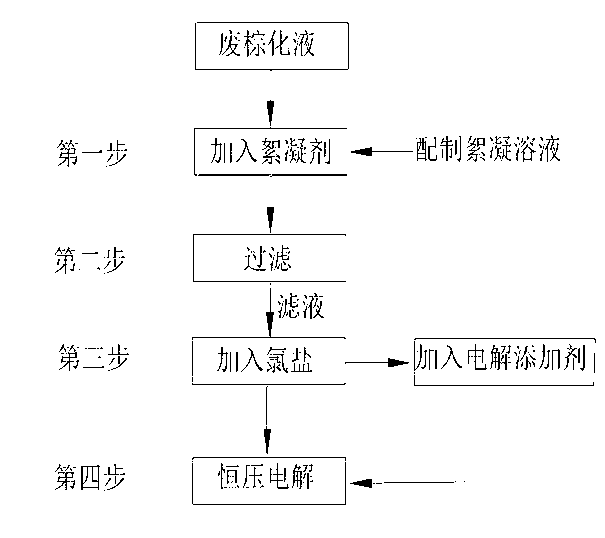

Image

Examples

Embodiment 1

[0038] At room temperature, add 50mL of prepared 2wt% polyacrylamide solution to 500mL of waste browning solution (the copper ion concentration is 28.9g / L), stir for 10min and filter, add 1g of sodium chloride to the filtrate, After stirring evenly, perform electrolysis in an insoluble titanium-based electrolytic cell covered with an indium oxide anode and a copper cathode, control a constant voltage of 10V, and a current density of 497A / m 2, After electrolysis for 1.5h, 14.35g copper was recovered, the copper recovery rate was 97.8%, mainly powdered copper.

Embodiment 2

[0040] Add 50mL of prepared 2 wt % polyacrylamide solution to 500mL of waste browning solution (the copper ion concentration is 28.9g / L), stir for 10min and then filter, add 1g of sodium chloride to the filtrate, add 10mL Add 0.01g of gelatin, thiourea, and casein with a mass ratio of 5:1:2 to the boiling water of 5:1:2 and mix the solids until they are completely dissolved. Then add them to 500mL of waste water. After stirring evenly, the insoluble titanium base is covered with indium oxide. Electrolysis is carried out in the electrolytic cell of the anode and the copper cathode, the constant voltage of 10V is controlled, and the current density is 489A / m 2 After 1.5 hours of electrolysis, 13.87g of bulk copper was recovered, the copper recovery rate was 96%, and the copper was mainly attached to the red copper.

Embodiment 3

[0042] Add 50mL of prepared 1 wt% polyacrylamide solution to 500mL of waste browning solution (the copper ion concentration is 41.3g / L), stir for 10min and then filter, add 5g of potassium chloride to the filtrate, add 10mL Add 0.03g of gelatin, thiourea, and casein with a mass ratio of 5:1:2 to the boiling water of 5:1:2 and mix the solids until they are completely dissolved. Then they are all added to 500mL of waste water. After stirring evenly, the insoluble titanium base is covered with indium oxide. Electrolysis is carried out in the electrolytic cell of the anode and the copper cathode, the constant voltage of 6V is controlled, and the current density is 425A / m 2 After 2.5 hours of electrolysis, 19.36g of bulk copper was recovered, the recovery rate of copper was 93.8%, and the copper was mainly attached to the red copper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com