A lead-acid storage battery grid whose surface layer is doped with rare earth elements and its preparation method

A technology of lead-acid batteries and rare earth elements, which is applied in the direction of electrode carriers/collectors, etc., can solve the problems of high gas evolution rate, large grid corrosion rate, and increased battery water loss rate, and achieve high hydrogen evolution and oxygen evolution overpotential, The effect of high corrosion resistance and high specific gravity capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

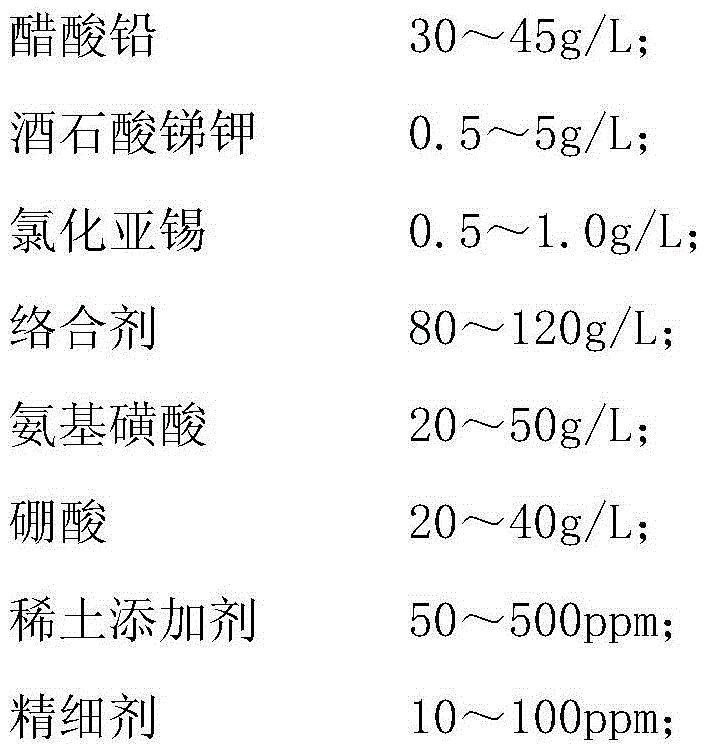

[0029] A method for preparing a lead-acid battery grid whose surface layer is doped with rare earth elements. In this embodiment, metal titanium is used as the base material, and the alloy surface layer of Pb-Sb-Sn doped with composite rare earth elements is obtained by plating in an electroplating solution. , the specific electroplating solution and working parameters are as follows: 40g / L of lead acetate, 2.2g / L of antimony potassium tartrate, 0.7g / L of stannous chloride, 120g / L of citric acid, and 35g / L of boric acid are mixed and dissolved completely. Adjust the pH to about 5, add 100ppm of cerium oxide, 100ppm of yttrium oxide and 100ppm of neodymium oxide, and add 20ppm of butynol propoxy compound BMP under the condition of sufficient stirring, and the plating solution configuration is completed. The lead plate is used as the anode, the titanium metal substrate is used as the cathode, and the electroplating is carried out in the charged tank (connected to the negative pol...

Embodiment 2

[0031] The present embodiment takes metal copper as the base material, and is electroplated in the following plating solution: lead acetate of 32g / L, potassium antimony tartrate of 4.5g / L, stannous chloride of 0.5g / L, citric acid 120g / L, 35g After the / L boric acid is mixed and dissolved completely, adjust the pH to about 5, add 200ppm of cerium oxide, 100ppm of yttrium oxide and 50ppm of neodymium oxide, and add 10ppm of N,N-diethylpropyne under the condition of full stirring After amine DEP, the plating solution configuration is complete. The lead plate is used as the anode, the copper metal substrate is used as the cathode, and the electroplating is carried out in the charged tank (connected to the negative pole of the DC power supply). The current density is controlled within the range of 2-3A / dm2, and the electrodeposition is 5-10 minutes, and 3-10 microns can be obtained. The main component of the coating is lead, and it contains about 3.5% of the metal antimony, 0.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com