Preparation method for nitrogen-doped porous carbon sphere-sulfur composite positive material

A nitrogen-doped porous carbon, composite cathode material technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of insufficient infiltration of sulfur salt solution, low sulfur content of composite materials, etc., and achieve high mechanical stability. High stability and simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Preparation of nitrogen-doped porous carbon spheres:

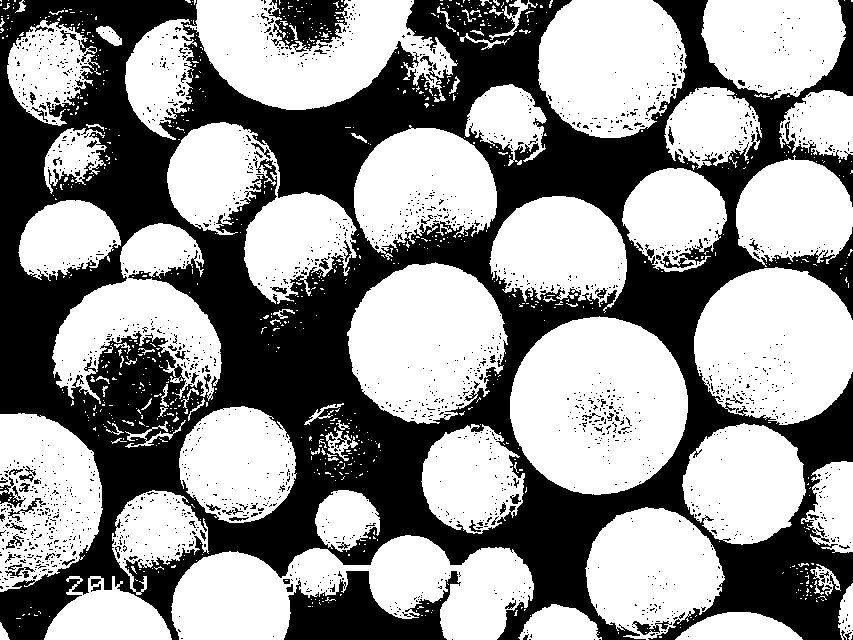

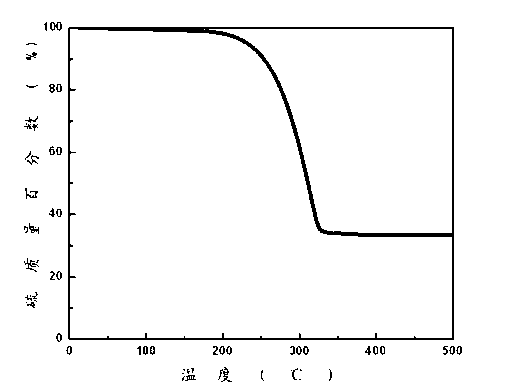

[0030] Weigh 30g biuret, 20g silica sol (SiO 2 Average particle size 7 nm, SiO 2 The concentration is 20 wt%), dissolved in 200 mL deionized water, and ultrasonically mixed for 1 h at 20 °C to make a spray solution. Put the spray solution into an argon gas stream spray pyrolyzer, spray pyrolyze at 400 °C, the atomization volume through the spray system is 0.5 mL / min, the medium gas atomization pressure is 1 MPa, collect the product, and obtain the nitrogen doped solution. Heteropyrolytic carbon-silica spherical composites. The complex was added to a hydrofluoric acid solution with a mass fraction of 10% and stirred at room temperature for 24 h to remove the template, then filtered with suction, washed three times with deionized water and absolute ethanol, and dried at 100°C to obtain nitrogen-doped Porous carbon spheres, whose SEM morphology is shown in Figure 1, the structure of carbon spheres doped with nitrog...

Embodiment 2

[0036] 1. Preparation of nitrogen-doped porous carbon spheres:

[0037] Weigh 40g triethanolamine, 30g silica sol (SiO 2 The particle size is 2 nm, the concentration is 30 wt%), dissolved in 200 mL deionized water, and ultrasonically mixed at 30 °C for 0.5 h to make a spray solution. Put the spray solution into an argon gas flow spray pyrolyzer, spray pyrolyze at 500 °C, the atomization volume through the spray system is 1 mL / min, the medium gas atomization pressure is 10 MPa, and the product is collected to obtain nitrogen-doped Pyrolytic carbon-silica spherical composite. The complex was added to a hydrofluoric acid solution with a mass fraction of 20% and stirred at room temperature for 12 h to remove the template, then suction filtered, washed repeatedly with deionized water and absolute ethanol, and dried at 100°C to obtain nitrogen-doped porous carbon spheres.

[0038] two, Preparation of nitrogen-doped porous carbon sphere-sulfur composite cathode material:

[003...

Embodiment 3

[0042] 1. Preparation of nitrogen-doped porous carbon spheres:

[0043] Weigh 35g dipropylamine, 25g silica sol (SiO 2 The particle size is 10 nm, the concentration is 40 wt%), dissolved in 200 mL deionized water, and ultrasonically mixed at 40 °C for 2 h to make a spray solution. Put the spray solution into the argon gas flow spray pyrolyzer, spray pyrolysis at 600 °C, the atomization volume through the spray system is 10 mL / min, the medium gas atomization pressure is 20 MPa, and the product is collected to obtain nitrogen-doped Pyrolytic carbon-silica spherical composite. The complex was added to a 30% hydrofluoric acid solution by mass and stirred at room temperature for 8 h to remove the template, then suction filtered, washed repeatedly with deionized water and absolute ethanol, and dried at 120°C to obtain nitrogen-doped porous carbon ball.

[0044] two, Preparation of nitrogen-doped porous carbon sphere-sulfur composite cathode material:

[0045] Put 0.4 g of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com