A low-rebound high-strength shotcrete reinforcement

A shotcrete and strengthening agent technology, applied in the field of concrete admixtures, can solve the problems of concrete quality control hazards, construction limitations, performance discounts, etc., so as to improve the mixing effect and measurement accuracy, optimize the mixing time, and maintain high stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The high-strength shotcrete strengthening agent with low resilience, high stability of the present invention can be prepared by the following preparation method, and the preparation method includes the following steps: (1) stirring the plant polysaccharide in a water bath to fully swell it to obtain Plant polysaccharide solution; (2) adding six-carbon water reducing agent and amphiphilic CNF to the plant polysaccharide solution and stirring rapidly to obtain a mixed solution; (3) adding rice husk ash to the mixed solution and stirring rapidly to obtain a fortifier.

[0028] In the preparation of the plant polysaccharide solution in step (1), the mass fraction of the plant polysaccharide needs to be controlled at 0.1wt%-0.5wt%. If the mass fraction is lower than 0.1 wt %, the viscosity of the obtained dispersion liquid is too low to play a role in thickening, and furthermore, it is impossible to disperse, suspend and stabilize admixtures such as rice husk ash. If it is p...

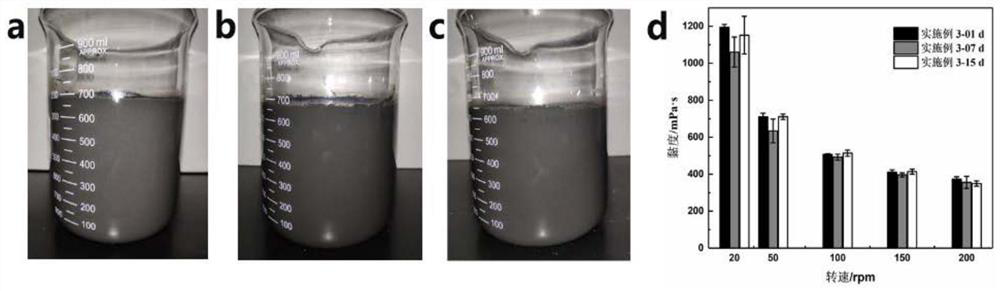

Embodiment 1

[0037] This embodiment provides a high-strength shotcrete strengthening agent with low resilience and high stability, comprising the following components in parts by weight: 560 parts of rice husk ash, 30 parts of amphiphilic CNF, 30 parts of polycarboxylate water reducing agent, konjac 0.38 parts of glucomannan, 380 parts of water. The concrete strengthening agent preparation method of the present embodiment, the concrete steps are as follows:

[0038] (1) 0.38g of konjac flour was evenly dispersed in 380mL of water, stirred and swollen in a 60°C water bath for 3h, fully swollen, and allowed to stand to cool to room temperature to obtain a konjac glucomannan solution with a mass fraction of 0.1wt%;

[0039] (2) pour 30g of amphiphilic CNF and 30g of polycarboxylate water reducing agent into konjac glucomannan solution, rapidly mix and stir for 8min at a rotating speed of 300r / min to obtain a mixed solution;

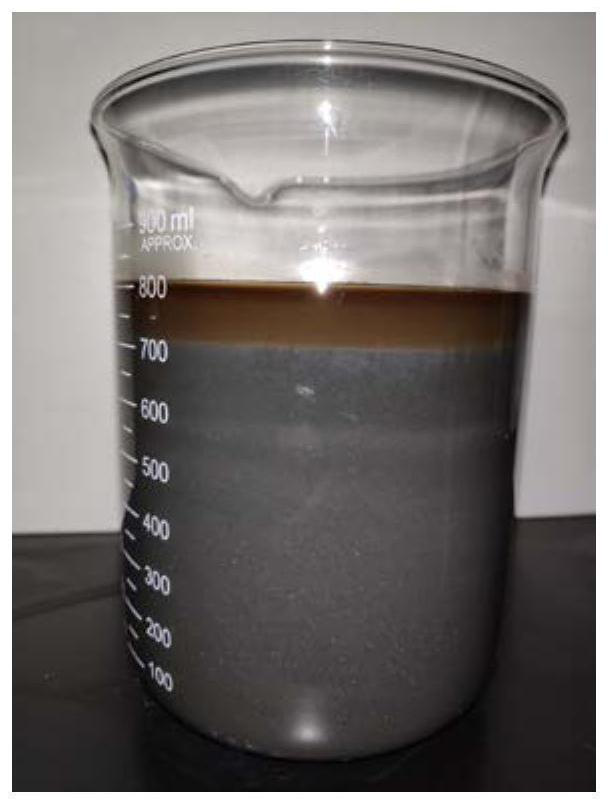

[0040] (3) Pour the rice husk ash into the mixed solution and stir...

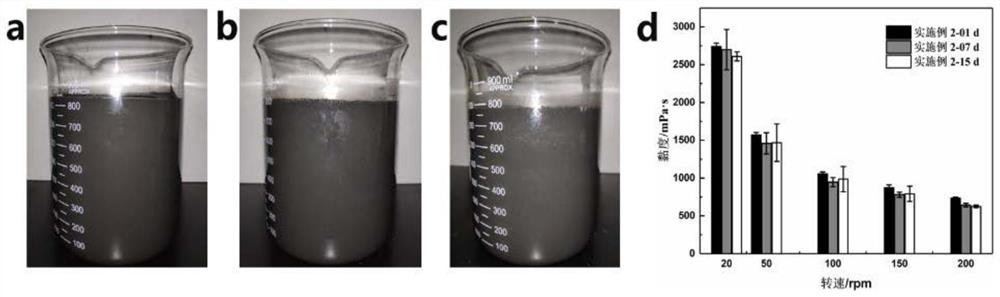

Embodiment 2

[0044] This embodiment provides a high-strength shotcrete strengthening agent with low resilience and high stability, comprising the following components by weight: 520 parts of rice husk ash, 20 parts of amphiphilic CNF, 20 parts of polycarboxylate water reducing agent, 0.88 parts of konjac glucomannan, 440 parts of water.

[0045] The concrete strengthening agent preparation method of the present embodiment, the concrete steps are as follows:

[0046] (1) 0.88g of konjac flour was uniformly dispersed in 440mL of water, stirred and swollen in a water bath at 80°C for 2h, fully swollen, and allowed to stand to cool to room temperature to obtain a konjac glucomannan solution with a mass fraction of 0.2wt%;

[0047] (2) pour 20g of amphiphilic CNF and 20g of polycarboxylate water-reducing agent into the konjac glucomannan solution, and rapidly mix and stir for 15min at a rotating speed of 260r / min to obtain a mixed solution;

[0048] (3) Pour 520 g of rice husk ash into the mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com