Novel airlift reactor with self-absorption aeration structure

An air-lift reactor, self-priming technology, applied in chemical/physical/physical-chemical fixed reactors, chemical methods for reacting liquids and gaseous media, chemical instruments and methods, etc. Difficult to enlarge, difficult to implement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

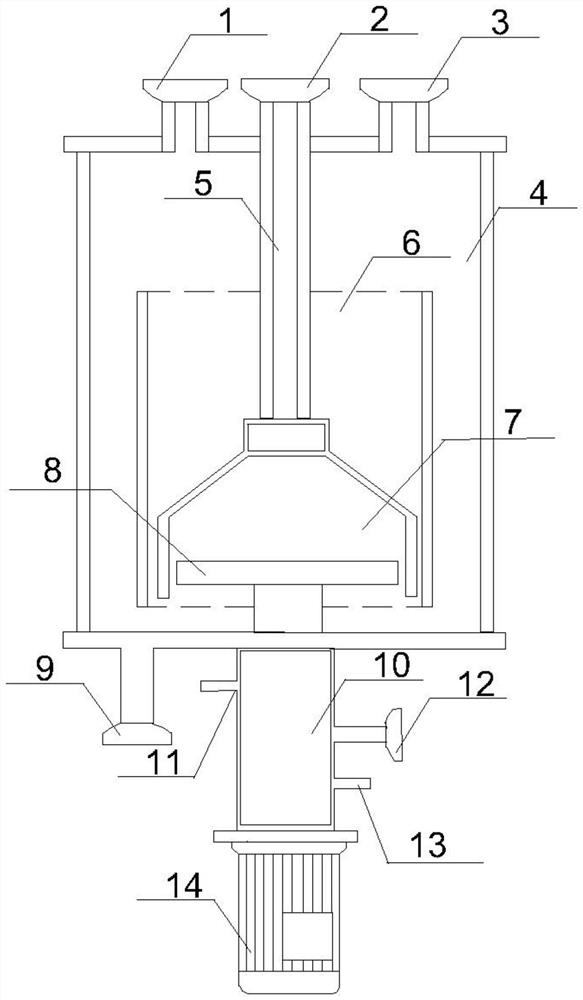

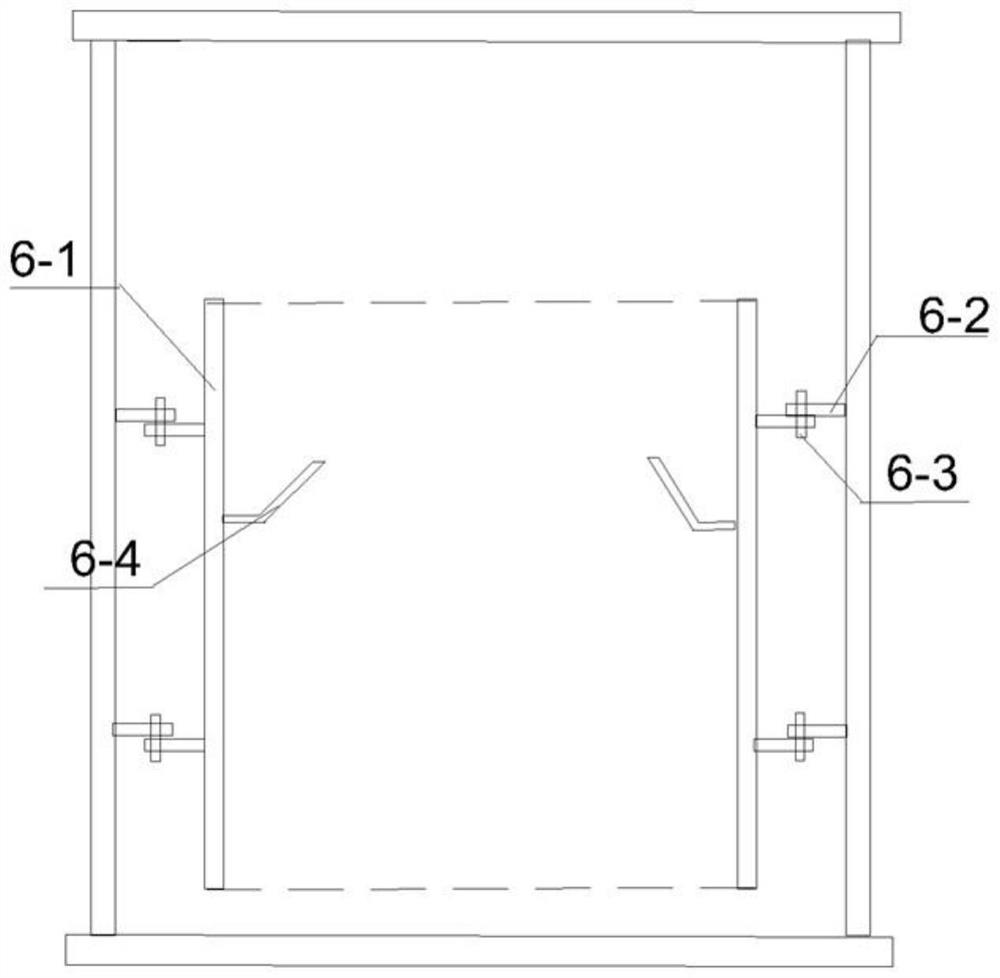

[0027] Such as Figure 1-Figure 3 As shown, a novel air-lift reactor with a self-priming aeration structure includes a reaction tank 4, and an upper end cover of the reaction tank 4 is provided with a liquid inlet 1, an upper air inlet 2 and an air outlet 3. The lower end cover of the reaction tank body 4 is provided with a drain port 9, a sealing member 10 and a generator 14, a cooling water inlet 11 is provided at the upper end of the side wall of the sealing member 10, and a cooling water inlet 11 is provided at the middle of the side wall. The lower air inlet 12, the lower part of the side wall is provided with a cooling water outlet 13, the generator 14 is fixed on the lower end surface of the seal 10, and the reaction tank 4 is provided with a guide tube 6 and a self-priming aerator. A gas distributor, the guide cylinder 6 is coaxially arranged with the reaction tank body 4, the diameter of the self-priming aeration gas distributor is smaller than the inner diameter of t...

Embodiment 2

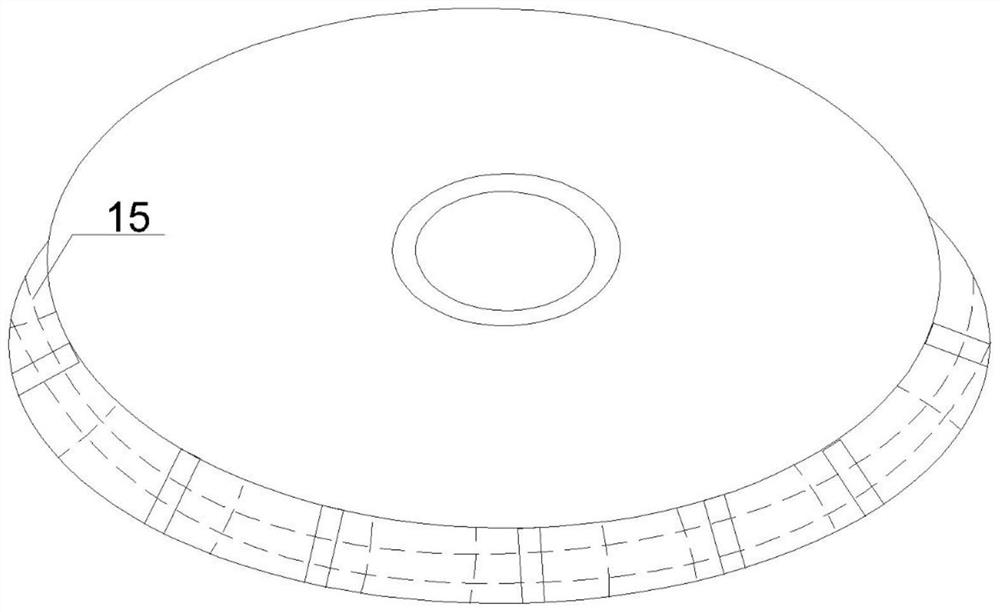

[0044] Such as Figure 1-Figure 3 and Figure 5 As shown, a novel air-lift reactor with a self-priming aeration structure includes a reaction tank 4, and an upper end cover of the reaction tank 4 is provided with a liquid inlet 1, an upper air inlet 2 and an air outlet 3. The lower end cover of the reaction tank body 4 is provided with a drain port 9, a sealing member 10 and a generator 14, a cooling water inlet 11 is provided at the upper end of the side wall of the sealing member 10, and a cooling water inlet 11 is provided at the middle of the side wall. The lower air inlet 12, the lower part of the side wall is provided with a cooling water outlet 13, the generator 14 is fixed on the lower end surface of the seal 10, and the reaction tank 4 is provided with a guide tube 6 and a self-priming aerator. A gas distributor, the guide cylinder 6 is coaxially arranged with the reaction tank body 4, the diameter of the self-priming aeration gas distributor is smaller than the inne...

Embodiment 3

[0054] Such as Figure 1-Figure 3 and Figure 6 As shown, a novel air-lift reactor with a self-priming aeration structure includes a reaction tank 4, and an upper end cover of the reaction tank 4 is provided with a liquid inlet 1, an upper air inlet 2 and an air outlet 3. The lower end cover of the reaction tank body 4 is provided with a drain port 9, a sealing member 10 and a generator 14, a cooling water inlet 11 is provided at the upper end of the side wall of the sealing member 10, and a cooling water inlet 11 is provided at the middle of the side wall. The lower air inlet 12, the lower part of the side wall is provided with a cooling water outlet 13, the generator 14 is fixed on the lower end surface of the seal 10, and the reaction tank 4 is provided with a guide tube 6 and a self-priming aerator. A gas distributor, the guide cylinder 6 is coaxially arranged with the reaction tank body 4, the diameter of the self-priming aeration gas distributor is smaller than the inne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com