Method for assisted preparation of carbon composite lithium iron phosphate micro-nanometer powder through industrially modified starch

A technology of lithium iron phosphate and modified starch, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of poor water solubility, cumbersome process, complicated preparation process, etc., and achieve cycle stability and rate performance Excellent, simple process steps, and uniform product scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

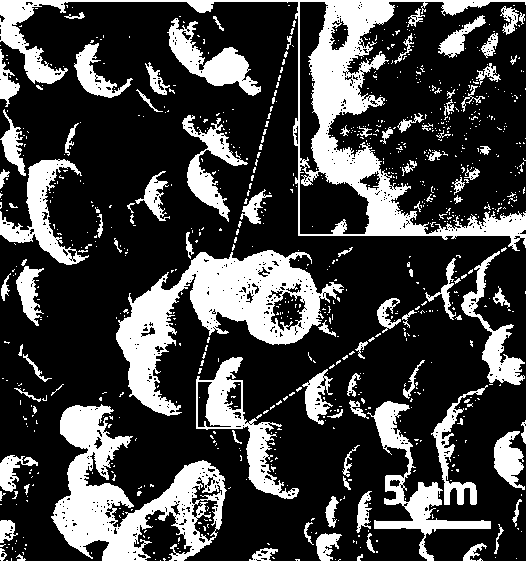

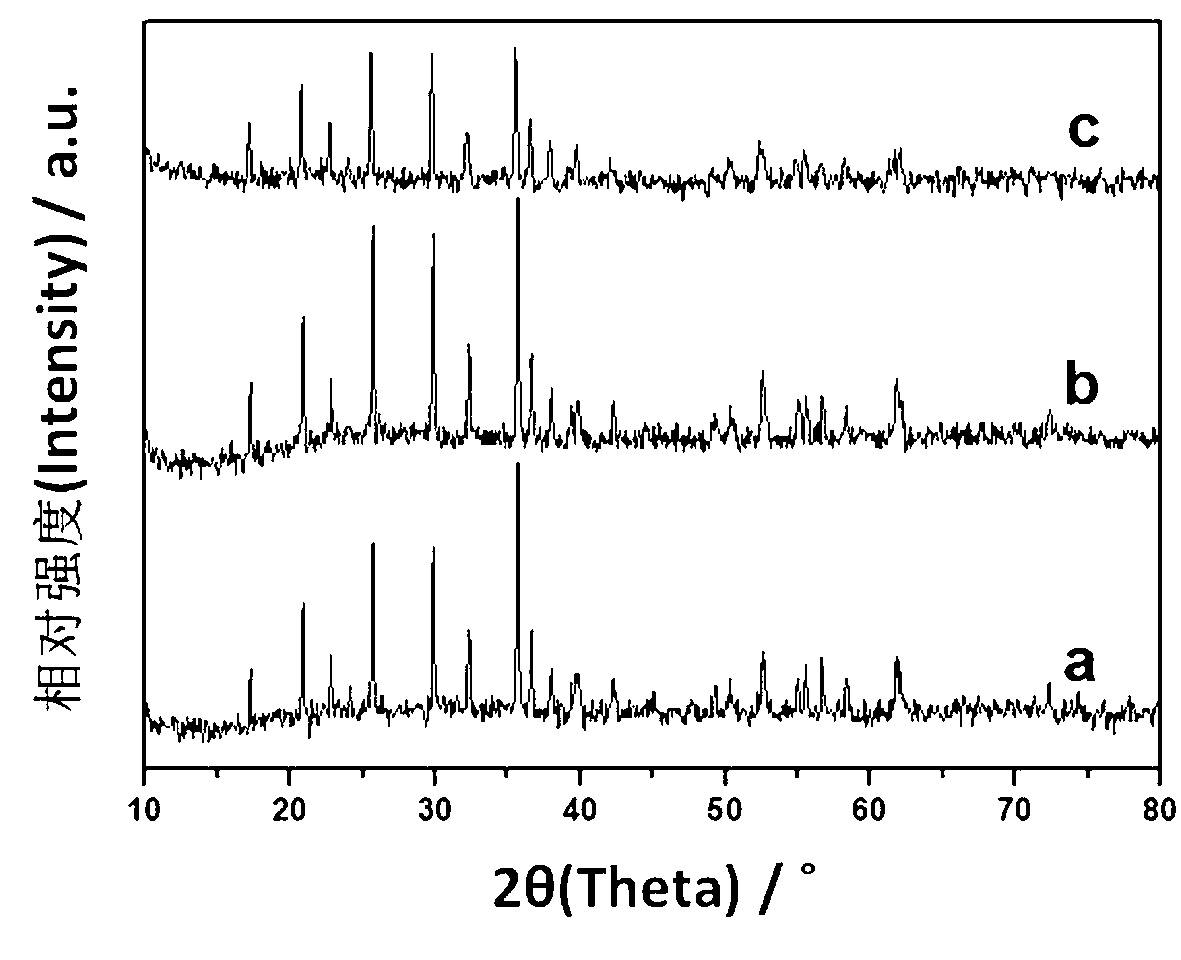

[0030] Weigh 18.7g of 0.1mol ferric phosphate dihydrate and 4.06g of 0.055mol lithium carbonate, weigh 8.2g of soluble starch and 3g of glucose according to 60% of the mass ratio of ferric phosphate, and mix the above weighing with 100mL of pure water at one time, After two high-energy ball mills and one sand mill successively, each operation time is 2h. Then the resulting suspension is sprayed and granulated through a spray drying tower to obtain a surface modification precursor. Place the precursor evenly in a magnetic boat, preheat in a sintering furnace at 350°C for 4 hours in a nitrogen atmosphere, and then calcinate at 700°C for 10 hours to obtain surface-modified lithium iron phosphate nanopowders (such as figure 1 As shown in the curve a), the particle size distribution D50 of the product is between 8 and 15 μm, which is agglomerated spheres of nanoparticles.

Embodiment 2

[0032] Weigh 15.08g of 0.1mol anhydrous iron phosphate and 4.06g of 0.055mol lithium carbonate, weigh 6.6g of soluble starch, 1g of cross-linked hydroxypropyl tapioca starch and 3g of glucose according to 70% of the mass ratio of iron phosphate, and mix the above The weighed material was mixed with 100mL of pure water, and then passed through two high-energy ball mills and one sand mill successively, each operation time was 2h. Then the resulting suspension is sprayed and granulated through a spray drying tower to obtain a surface modification precursor. Place the precursor evenly in a magnetic boat, preheat in a sintering furnace at 350°C for 4 hours in a nitrogen atmosphere, and then calcinate at 700°C for 10 hours to obtain a surface-modified lithium iron phosphate powder (such as figure 1 As shown in the curve b in), the particle size distribution D50 of the product is between 5 and 10 μm, which is agglomerated spheres of nanoparticles.

Embodiment 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com