Equipment and method for preparing microcapsules by liquid-liquid electrostatic micro-jet atomization

A microcapsule and microjet technology, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of unstable electrostatic cone jet atomization, easy oxidation, pollution, poor uniformity of droplet particle size, etc., to achieve monodispersion. Good performance, preventing medium pollution, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

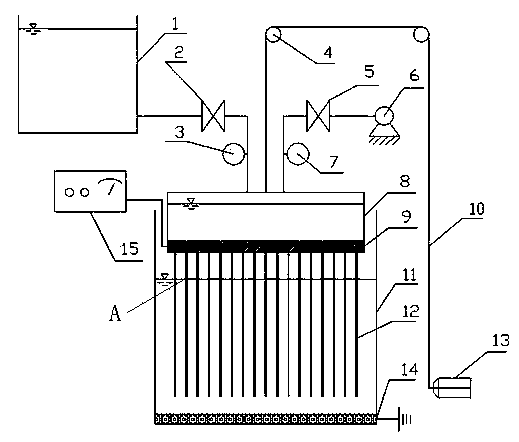

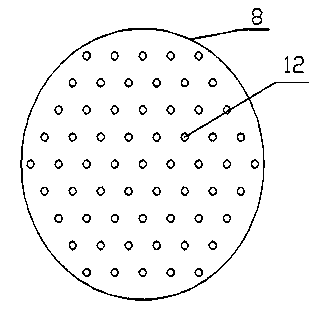

[0018] see figure 1 , a liquid-liquid electrostatic micro-jet atomization preparation microcapsule equipment of the present invention has a finished microcapsule reaction collector 11, and the finished microcapsule reaction collector 11 has a working liquid tank 8, a metal capillary 12, a solidification liquid and a base in the cavity Electrode 14, the finished microcapsule reaction collector 11 is an insulating cylindrical structure, and a flat base electrode 14 is housed on the inner bottom surface of the cylinder, the base electrode 14 is grounded, and the potential is zero; the working liquid tank 8 is a Cylindrical closed container, the bottom surface of the working liquid tank 8 is fixedly connected to the upper ends of several metal capillaries 12, all the metal capillaries 12 are connected with the working liquid tank 8, and the lower ends of the metal capillaries 12 are vertically suspended in the finished microcapsule reaction collection In the container 11, also all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com