Novel green single-dispersed silica nanoparticle preparation method

A technology of silica and nanospheres, applied in the field of nanomaterials, can solve the problems of difficulty in obtaining high-quality SiO2 nanospheres, poor controllability and repeatability of silica nanospheres, and difficulty in recycling, and achieve uniform morphology. , The system can be reused and the appearance is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

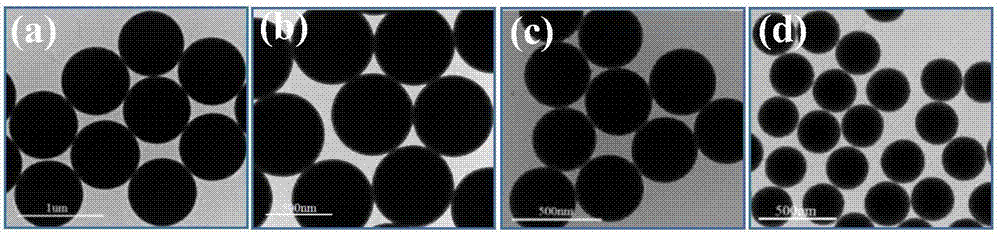

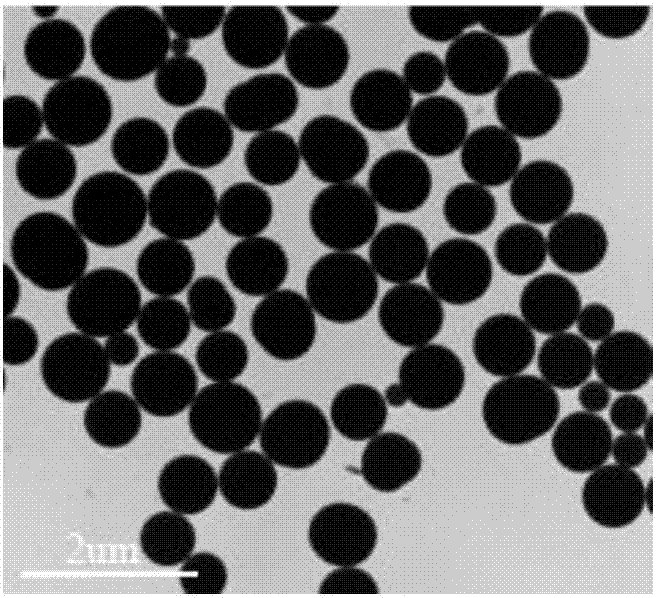

Embodiment 1

[0042] (1) Mix 4 g of secondary ultrapure water with 76 g of ethanol, add 20 g of dichloromethane under stirring conditions, and continue stirring for 10 min after the addition is complete.

[0043] (2) 1.3 ml of ethyl orthosilicate was slowly added to the O / W surfactant-free microemulsion system obtained in step (1) under stirring, followed by sonicating for 10 minutes and stirring for 20 minutes after the addition was completed.

[0044] (3) The O / W type surfactant-free microemulsion system containing ethyl orthosilicate obtained in step (2) is moved into an ice-water bath, and under stirring conditions, 3ml of ammonia water (25wt﹪) is slowly added therein, and stirring is continued for 10min Then, the reaction apparatus was moved into a 25°C water bath and allowed to react for 6h.

[0045] (4) After the reaction is completed, a white solid is obtained by centrifugation, and the white solid is washed three times to obtain SiO 2 Nanospheres. The remaining liquid fractions w...

Embodiment 2

[0047] (1) Mix 4g of secondary ultrapure water with 36g of ethanol, add 10g of dichloromethane under stirring conditions, and continue to stir for 10min after the addition is complete.

[0048] (2) 1.3 ml of ethyl orthosilicate was slowly added to the O / W surfactant-free microemulsion system obtained in step (1) under stirring, followed by sonicating for 10 minutes and stirring for 20 minutes after the addition was completed.

[0049] (3) The O / W type surfactant-free microemulsion system containing ethyl orthosilicate obtained in step (2) is moved into an ice-water bath, and under stirring conditions, 3ml of ammonia water (25wt﹪) is slowly added therein, and stirring is continued for 10min Then, the reaction apparatus was moved into a 25°C water bath and allowed to react for 6h.

[0050] (4) After the reaction is completed, a white solid is obtained by centrifugation, and the white solid is washed three times to obtain SiO 2 Nanospheres. The remaining liquid fractions were d...

Embodiment 3

[0052] (1) Mix 4g of secondary ultrapure water with 16g of ethanol, add 5g of dichloromethane under stirring conditions, and continue stirring for 10min after the addition.

[0053] (2) 1.3 ml of ethyl orthosilicate was slowly added to the O / W surfactant-free microemulsion system obtained in step (1) under stirring, followed by sonicating for 10 minutes and stirring for 20 minutes after the addition was completed.

[0054] (3) The O / W type surfactant-free microemulsion system containing ethyl orthosilicate obtained in step (2) is moved into an ice-water bath, and under stirring conditions, 3ml of ammonia water (25wt﹪) is slowly added therein, and stirring is continued for 10min Then, the reaction apparatus was moved into a 25°C water bath and allowed to react for 6h.

[0055] (4) After the reaction is completed, a white solid is obtained by centrifugation, and the white solid is washed three times to obtain SiO 2 Nanospheres. The remaining liquid fractions were distilled, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com