Metal rust-preventive oil comprising chlorobutanol

A trichloro-tert-butanol and metal anti-rust technology, applied in the field of metal anti-rust oil, can solve problems such as insufficient anti-rust effect, and achieve excellent contact anti-rust performance, good gas-phase anti-rust effect, and good gas-phase anti-rust effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

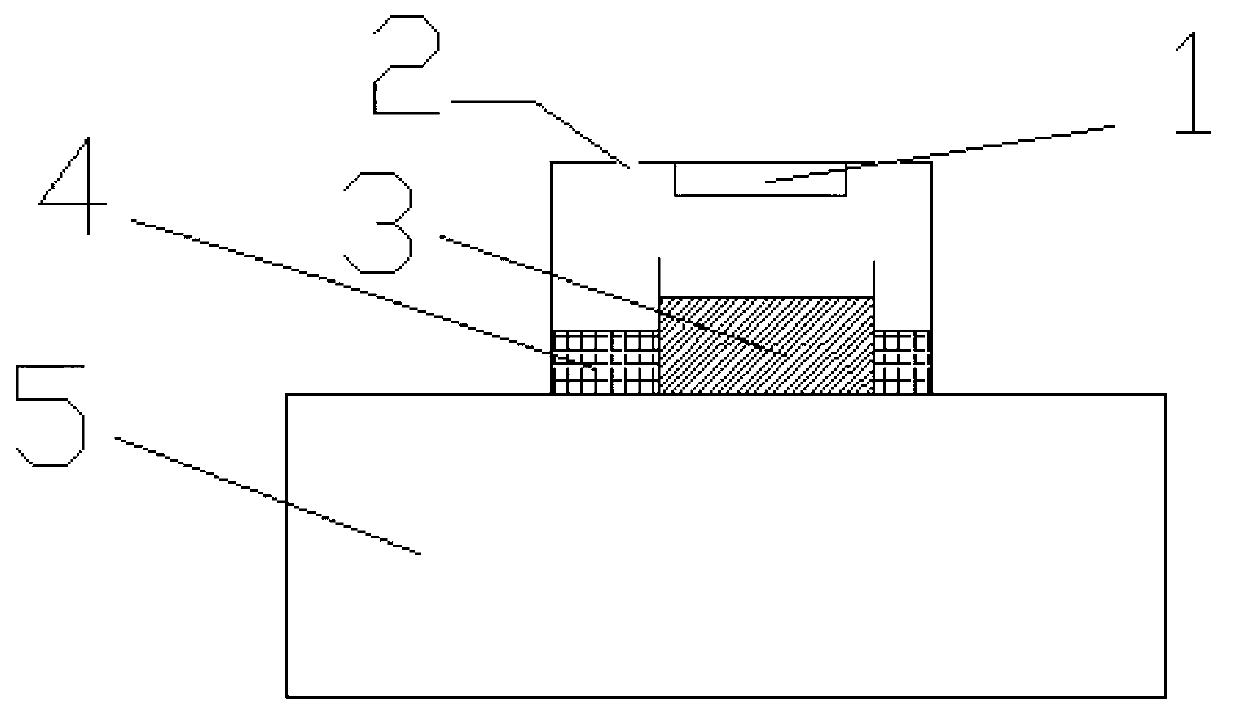

Image

Examples

Embodiment Construction

[0015] A kind of metal antirust oil containing chlorobutanol, it is made by the raw material of following parts by weight (kg):

[0016] No. 120 solvent oil 110, antioxidant 1135 0.5, antioxidant 1076 0.3, sorbitan monooleate 0.4, triethanolamine oleate 1.6, octyl epoxy stearate 0.5, zinc naphthenate 0.4, magnesium naphthenate 0.4, silane coupling agent KH550 2.4, silane coupling agent A171 1.4, microcrystalline wax 2.5, octamethylcyclotetrasiloxane 0.6, acetone 1.5, monoethanolamine 0.6, barium petroleum sulfonate 0.4, sodium lauryl sulfate 0.4, glyceryl monostearate 0.1, benzotriazole 1.4, 2-aminoethylheptadecenyl imidazoline 2.5, zinc stearate 0.3, Pingpingjia 0.6, chlorobutanol 1.1, modified nano Attapulgite 0.5, composite film-forming material 7.1;

[0017] The composite film-forming material is prepared from the following raw materials in parts by weight: No. 120 solvent oil 68, C5 petroleum resin 42, dioctyl sebacate 1.8, lauryl polyoxyethylene ether 8, methyl acetate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com