A cross-linked weather-resistant polyolefin composition suitable for machine processing of adhesive tape, adhesive cloth made of the same, and method for manufacturing the adhesive cloth

A technology of polyolefin and composition, which is applied in the field of cross-linked weather-resistant polyolefin plastic tape and its preparation method, can solve the problems of inability to uniformly extrude cross-linked polyolefin tape, affecting the quality of cross-linked polyolefin film, cross-linked polyolefin Solve the coking problem of olefin tape and other problems, and achieve the effects of low processing cost, excellent film surface quality, good heat resistance and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

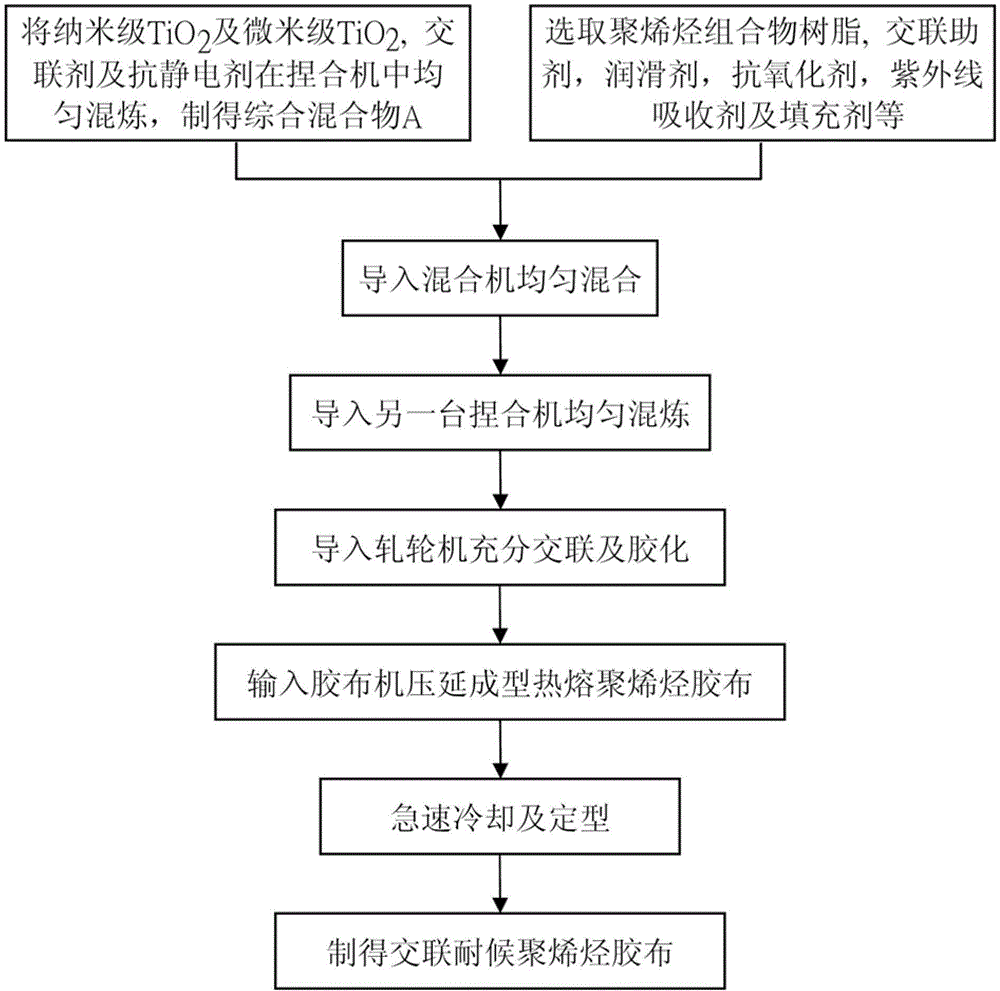

Method used

Image

Examples

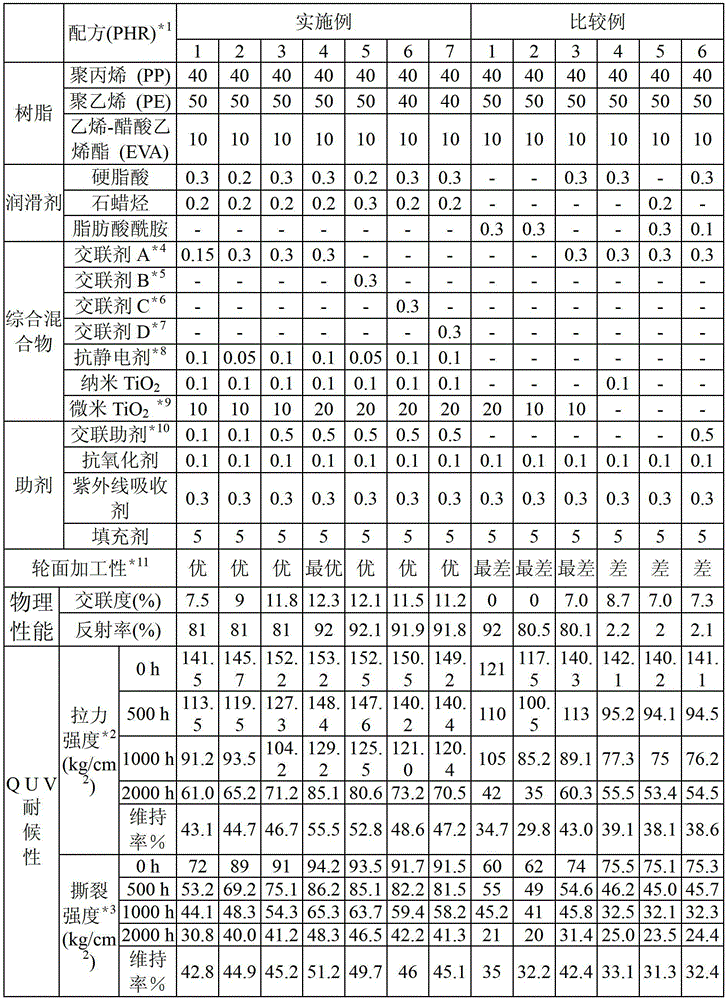

Embodiment 1

[0074] The cross-linked weather-resistant polyolefin tape with a thickness of 0.10mm (hereinafter referred to as cross-linked polyolefin tape) is produced according to the following method:

[0075] 1. prepare comprehensive mixture according to the embodiment 1 formula of table 1, micron TiO 2 The content is 10PHR.

[0076] 2. According to the formula of Example 1 in Table 1, polyolefin mixture resin (wherein the VA content of EVA is 8~33%), comprehensive mixture, lubricant, auxiliary agent (comprising cross-linking auxiliary agent of 0.1PHR, 0.1PHR Antioxidant, 0.3PHR UV absorber and 0.5PHR filler) and other raw materials are mixed evenly with a mixer, and then introduced into the kneader for uniform mixing and gelation. At the decomposition temperature of organic peroxide;

[0077] 3. Then, it is introduced into the rolling machine again, and the temperature of the material is controlled at 150°C to 220°C. After sufficient cross-linking, the mixed material is introduced in...

Embodiment 2

[0080] 1. According to the embodiment 2 formula of table 1, prepare comprehensive mixture, micron TiO 2 The content is 10PHR.

[0081] 2. with the preparation method of embodiment 1, the cross-linked polyolefin adhesive plaster of 0.1mm thickness is made into the cross-linked polyolefin adhesive plaster of 0.1mm thickness with the use of cross-linking auxiliary agent in table 1 as the embodiment 2 formula of 0.1PHR, and its degree of cross-linking is 9%, and the tensile strength is 145.7kg / cm 2 And the tear strength is 89kg / cm 2 ; After 2000h of QUV irradiation, the tensile strength can maintain 44.7%, and the tear strength can maintain 44.9%.

Embodiment 3

[0083] 1. according to the embodiment 3 prescription of table 1, prepare comprehensive mixture, micron TiO 2 The content is 10PHR.

[0084] 2. with the preparation method of embodiment 1, the cross-linked polyolefin adhesive plaster of 0.1mm thickness is made into the cross-linked polyolefin adhesive plaster of 0.1mm thickness with the use of cross-linking auxiliary agent in table 1 as the embodiment 3 formula of 0.5PHR, and its degree of cross-linking is 11.8%, and the tensile strength is 152.2kg / cm 2 , and the tear strength is 91kg / cm 2 ; After 2000 hours of QUV irradiation, the tensile strength can maintain 46.7%, and the tear strength can maintain 45.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com