Aquaculture water purification agent and preparation method thereof

A technology for aquaculture and purifiers, which is applied in the field of purifiers and water quality purifiers. It can solve the problems that coagulants can only coagulate for a period of time, the amount of oxidant is small and have no effect, and flocculants can only flocculate, so as to achieve obvious water quality purification. And thorough, fast and thorough purification, ingeniously designed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

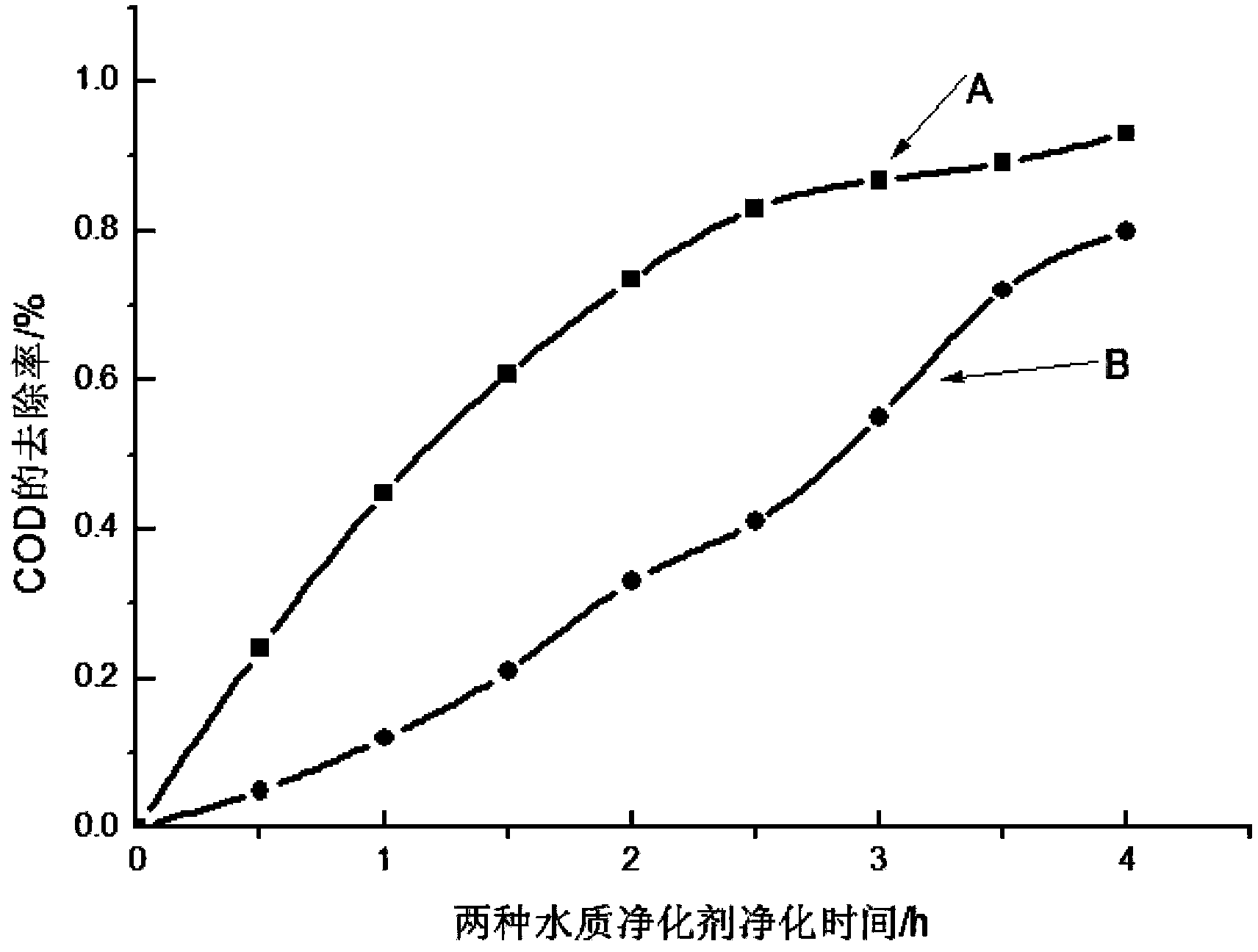

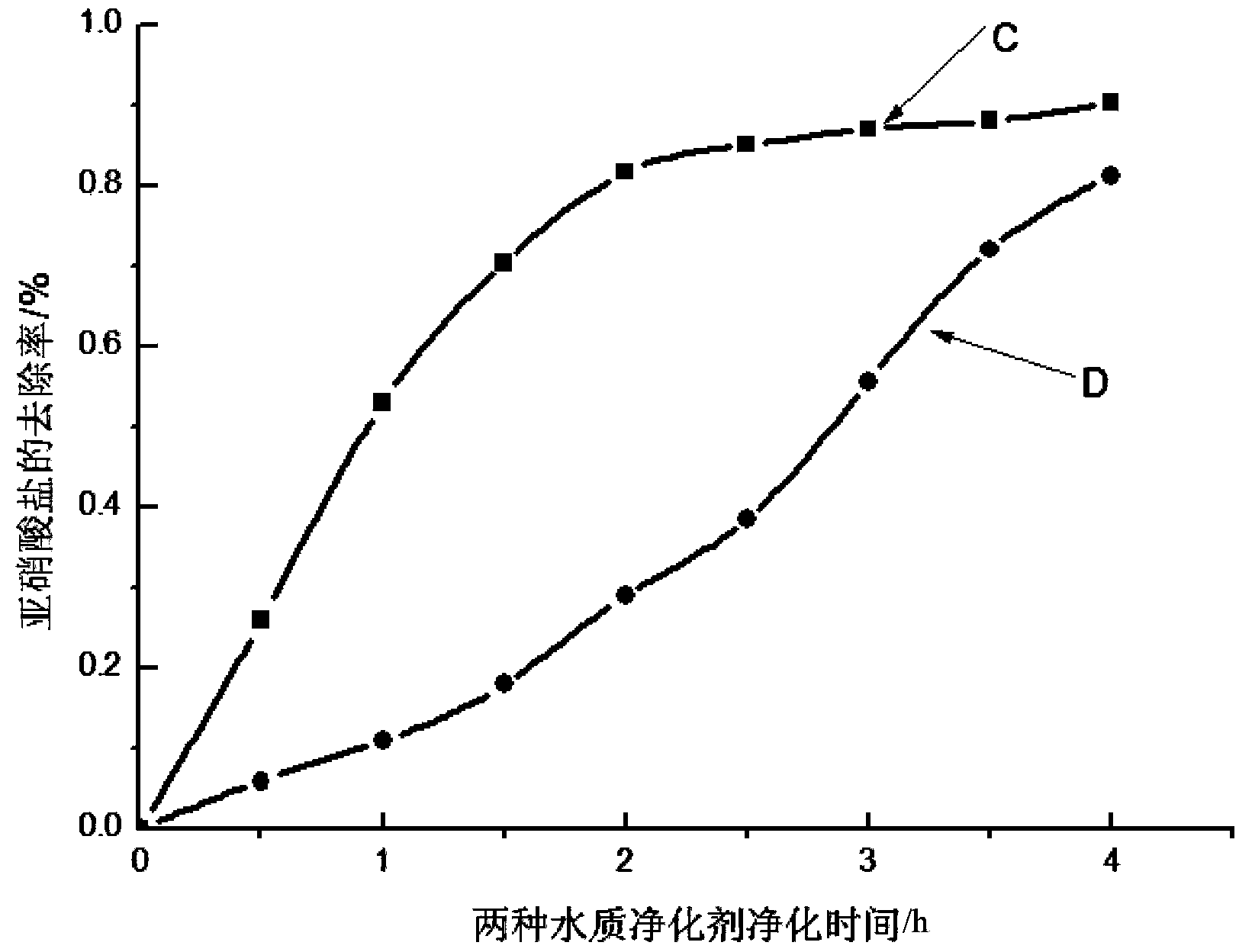

[0027] 1.3 Preparation of two kinds of water purifiers

[0028] Take 200-300 parts by weight of polyaluminium chloride, 200-300 parts by weight of potassium ferrate, 0.1-20 parts by weight of cationic polyacrylamide, 1-20 parts by weight of sulfur powder, 10-100 parts by weight of activated carbon, 2-40 parts by weight of calcium oxide, 100-300 parts by weight of zeolite powder, 100-300 parts by weight of diatomaceous earth, and 0.1-5 parts by weight of CuSO4 are put into a high-speed pulverizer for pulverization and mixed uniformly, and the samples are taken out and dried After passing through a 70-mesh sieve and sealing, the aquaculture water purifier powder of the present invention is obtained.

[0029] With reference to Chinese patent application CN101306859A, similar water quality purifiers are obtained.

[0030] 1.4 Determination of several biochemical indicators

[0031] pH: Measured according to GB / T9620 glass electrode method;

[0032] COD: measured according to GB...

Embodiment 1

[0062] Get 200 parts by weight of polyaluminium chloride, 300 parts by weight of potassium ferrate, 0.1 part by weight of cationic polyacrylamide, 1 part of sulfur powder, 10 parts by weight of activated carbon, 40 parts by weight of calcium oxide, and 300 parts by weight of zeolite powder, 100 parts by weight of diatomite, and 0.1 parts by weight of CuSO 4 are put into a high-speed pulverizer and pulverized and mixed evenly. After the sample is taken and dried, it is sealed through a 70-mesh sieve to obtain a novel water purifying agent powder.

[0063] The corresponding effects of the above water purifiers are as follows

[0064] It is used in a breeding fish pond in Lingang, Shanghai, with an area of 2 mu. The water quality of the spring pond is too thick, the water color is not good, and the ammonia nitrogen, nitrite, COD and heavy metal copper ions in the water quality reach 1.35mg·L respectively. -1 , 0.52mg·L -1 , 70.36mg·L -1 , 0.08mg·L -1 The bottom is black and ...

Embodiment 2

[0070] Get 250 parts by weight of polyaluminum chloride, 250 parts by weight of potassium ferrate, 10 parts by weight of cationic polyacrylamide, 10 parts of sulfur powder, 50 parts by weight of activated carbon, 20 parts by weight of calcium oxide, and 200 parts by weight of zeolite powder, 200 parts by weight of diatomite, and 2.5 parts by weight of CuSO 4 are put into a high-speed pulverizer and pulverized and mixed uniformly. After the sample is taken and dried, it is sealed through a 70-mesh sieve to obtain a novel water purifying agent powder.

[0071] The corresponding effects of the above water purifiers are as follows

[0072] It is used in a breeding fish pond in Lingang, Shanghai, with an area of 2 mu. The water quality of the spring pond is too thick, the water color is not good, and the ammonia nitrogen, nitrite, COD and heavy metal copper ions in the water quality reach 1.48mg·L respectively. -1 , 0.36mg·L -1 , 71.2mg·L -1 , 0.09mg·L -1The bottom is black an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com