Carbonaceous shale inhibitor and flotation separation method of molybdenum sulfide and carbonaceous shale flotation mixed concentrate

A carbonaceous shale and mixed concentrate technology, applied in flotation, solid separation, etc., can solve the problems of difficult large-scale promotion, high energy consumption, and high toxicity of nigrosine, and achieve easy large-scale promotion and simplified process flow , the effect of good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

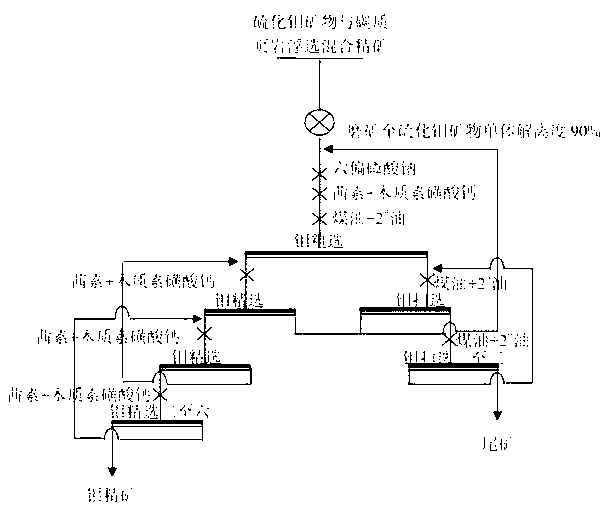

Method used

Image

Examples

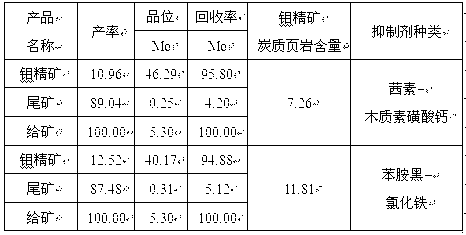

Embodiment 1

[0033] The molybdenum grade of a molybdenum sulfide and carbonaceous shale flotation mixed concentrate is 5.30%, the molybdenum mineral is mainly molybdenite, the gangue mineral is mainly carbonaceous shale, and the carbonaceous shale content is 81%. Grinding, the monomer dissociation degree of molybdenum mineral is 94%.

[0034] The molybdenum sulfide and carbonaceous shale flotation mixed concentrate are adjusted to a slurry concentration of 33%, and 80 g / t of sodium hexametaphosphate is added to the ore, and the carbonaceous shale inhibitor 120 g / t of the present invention is added to the ore (alizarin 80g / t ore supply, calcium lignosulfonate 40g / t ore supply), kerosene 40g / t ore supply, 2 # Oil 20g / t is fed to the ore, and molybdenum roughing is carried out to obtain rough molybdenum concentrate and roughing tailings, and the roughing tailings are added with kerosene and 2 # oil for scavenging, scavenging 1 kerosene and 2 # The amount of oil added is 12g / t for ore and 10...

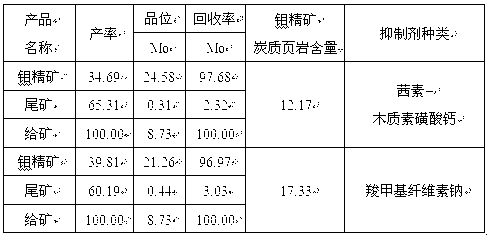

Embodiment 2

[0042] The molybdenum grade of a mixed molybdenum sulfide mineral and carbonaceous shale is 8.73%. The molybdenum mineral is mainly colloidal molybdenum ore. The degree is 92%.

[0043]The mixed ore of molybdenum sulfide and carbonaceous shale is adjusted to a pulp concentration of 33%, and the dispersion inhibitor sodium hexametaphosphate 130g / t is sequentially added to the ore, and the carbonaceous shale inhibitor described in claim 1 or 2 is fed to the ore at 180g / t (Alizarin 120g / t ore supply, calcium lignosulfonate 60g / t ore supply), molybdenum sulfide mineral inhibitor kerosene 45g / t ore supply, 2 # Oil 20g / t is fed to the ore, and molybdenum roughing is carried out to obtain rough molybdenum concentrate and roughing tailings, and the roughing tailings are added with kerosene and 2 # oil for scavenging, scavenging 1 kerosene and 2 # The amount of oil added is 15g / t for ore and 10g / t for ore, and the second kerosene and 2 # The amount of oil added is 10g / t for ore and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com