Heating flexible transparent thin film printed with silver paste and carbon paste and production method thereof

A technology of transparent film and heating film, which is applied in the direction of electric heating devices, ohmic resistance heating, heating element materials, etc. It can solve the problems of not meeting energy saving and improving thermal efficiency, uneven heating density, thick and clumsy, etc., and achieve uniform design and production. Low cost, reliable texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

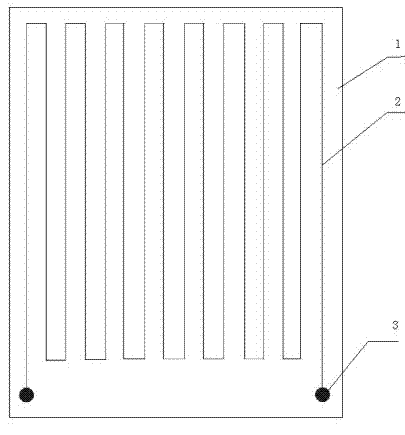

Embodiment approach 1

[0027] A preparation method for printing a heat-generating flexible transparent film with silver paste and carbon paste, the steps are as follows:

[0028] 1. Preparation: carbon paste, conductive silver paste, TIE transparent plastic film with a thickness of 0.02-0.05, and nylon mesh with a mesh number of 200; the high temperature resistance of the TIE transparent plastic film is 160°C.

[0029] 2. To prepare high-performance plasma ink, first select highly conductive carbon paste: the mesh fineness of graphite powder is 99.9%, conductive silver paste: the mesh fineness of silver powder is 99.9%,

[0030] 1) The weight percentage distribution of graphite carbon is as follows: silicone rubber emulsion 56%, accelerator 2%, antioxidant 2%, stearic acid 3%, superconducting graphite powder 37%; volume specific conductivity 12~15 ;

[0031] 2) The proportion of silver paste is as follows: 58% silicone rubber emulsion, 2% accelerator, 2% anti-aging agent, 3% stearic acid, 35% supe...

Embodiment approach 2

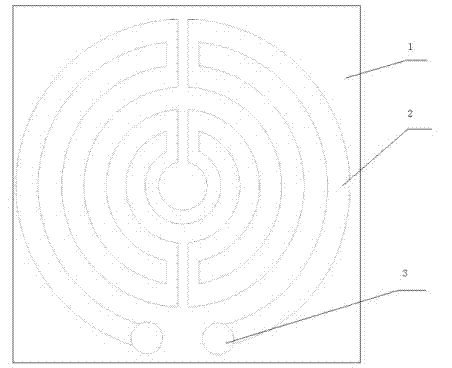

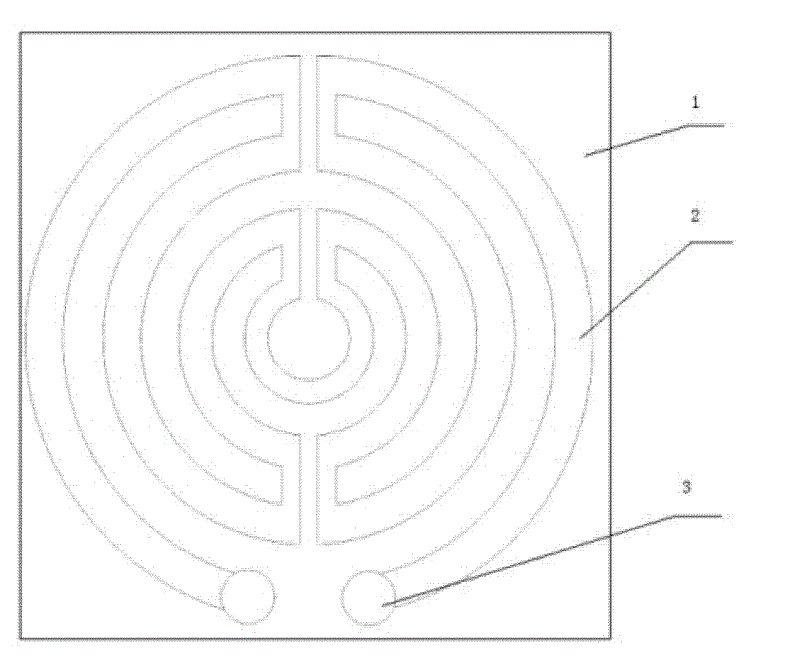

[0039] A kind of preparation method of the flexible transparent film that prints heat with silver paste, carbon paste, its steps are as follows: On the basis of embodiment 1, replace plastic film with TIE transparent plastic film and be polyamide ammonium film, the temperature of high temperature resistance It is 260°C. Polyamide ammonium film in 50㎝ 2 up to 250cm 2 The voltage of the large heating film is 110V~220V, and the heating line is a wide conductive film layer. The conductive heating film layer circuit is a circular "electric hob-type" wiring circuit. Such as figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com