Method for gold separation by means of removing antimony

A technology for removing antimony and selecting gold, which is applied in the fields of mineral processing and gold and antimony recovery by wet metallurgy technology, can solve problems such as waste of gold and antimony resources, and achieve the effect of simplifying process conditions and fully utilizing thermal energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

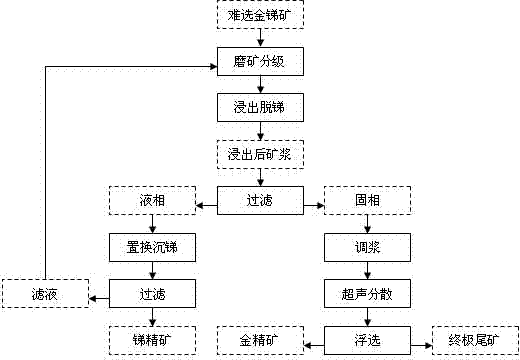

[0060] Example 1: A gold-antimony separation and smelting process that realizes antimony removal and gold separation

[0061] from figure 1It can be seen that the present invention is a gold antimony beneficiation and smelting process for realizing the deantimony gold separation method. The refractory gold antimony ore is treated by leaching and deantimony method, so that the antimony enters the liquid phase in the ionic state, and the gold remains in the crystalline state. Solid phase; solid-liquid separation of leached ore pulp to produce liquid phase and solid phase; liquid phase is treated by displacement and antimony precipitation method to make antimony change from ionic state to crystalline state; solid phase is treated by flotation method to make elemental gold And gold-loaded sulfide ore and gangue separation. The refractory gold-antimony ore at least includes elemental gold and gold-bearing minerals; the elemental gold includes visible gold and invisible gold; Su...

Embodiment 2

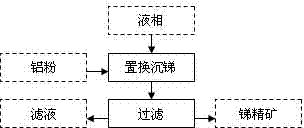

[0063] Example 2: A Displacement Antimony Precipitation Process for Realizing Antimony Removal, Gold Separation and Smelting Process

[0064] from figure 2 It can be seen that the present invention is a displacement antimony deposition process for realizing the deantimony gold separation method. To the liquid phase produced by the pulp after filtration and leaching, aluminum powder of -0.074mm and 100% is added to replace antimony deposition, and the output Antimony concentrate and filtrate after antimony precipitation.

[0065] Although the reaction rate of the replacement antimony precipitation process is faster in acidic environment, considering the direct recycling of the filtrate after antimony precipitation and the alkaline environment requirements of the leaching and deantimony process, it is especially necessary to inhibit the dissolution of arsenopyrite The ionic arsenic produces a large amount of arsine waste gas in the process of replacing antimony and depositin...

Embodiment 3

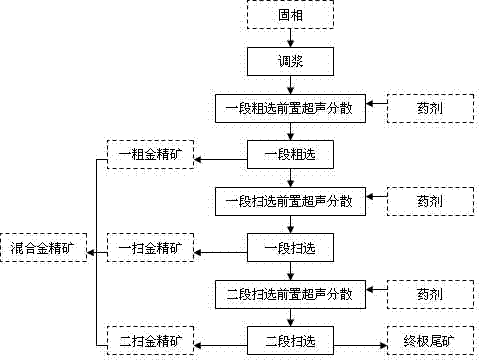

[0067] Example 3: An Ultrasonic Flotation Process for Realizing Deantimony Gold Separation and Smelting Process

[0068] from image 3 It can be seen that the present invention is an ultrasonic flotation process for realizing the deantimony gold separation method. After filtering and leaching the solid phase of the ore pulp output, water is added to adjust the slurry, and the output solid-liquid ratio is 1:2-2.5 after slurry adjustment. Ore pulp; Add a stage of roughing agent to the slurry after pulp adjustment, perform a stage of roughing pre-ultrasonic dispersion and a stage of roughing, and produce a coarse gold concentrate and a rough tailing; add a stage of sweeping agent to a rough tailings, One-stage sweeping pre-ultrasonic dispersion and one-stage sweeping, output one-stage gold concentrate and one-stage tailings; add second-stage sweeping agent to the first-stage tailings, and perform two-stage pre-sweep ultrasonic dispersion and two-stage sweeping, The output of E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Liquidus temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com