Palladium-based catalyst for methane catalytic combustion and preparation of palladium-based catalyst

A methane catalytic combustion and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of poor low temperature activity and high ignition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0016] Specific embodiment 1: Take by weighing 10 g of pseudo-boehmite, industrial grade, with a water loss rate of 15%, dissolve it in 150 mL of deionized water, add dilute nitric acid dropwise after stirring for 30 min, and adjust the pH value of the system to be 3 . Add 5 g of sodium dodecyl sulfate (SDS) to the above system, stir for 180 min, and put the sample into an electric drying oven at 100 °C for drying. After 10 h, the dried samples were transferred to a muffle furnace at a rate of 5 °C / min to 600 °C, and then roasted at a constant temperature for 4 h. Calcined for 4 h to obtain mesoporous alumina. It was then added to 0.605 mL of Pd(NO 3 ) 2 solution (with a noble metal content of 78 g / L), equal volumes were impregnated onto the mesoporous alumina support, and the impregnated sample was dried overnight at 110 °C, and then calcined in a muffle furnace at 600 °C for 2 h to obtain a supported palladium catalyst. Weighed 1g of catalyst and loaded it into a 5 mm qu...

specific Embodiment 2

[0017] Specific Example 2: Weigh 10 g of pseudo-boehmite, industrial grade, with a water loss rate of 15%, dissolve it in 150 mL of deionized water, stir for 30 min and add dilute nitric acid dropwise to adjust the pH of the system to 3. At this time, the pseudo-boehmite is in a sol state, and ammonia water is added to reverse the pH value of the system to 10. 5 g of cetyltrimethylammonium bromide (CTAB) was added to the above system, stirred for 180 min, and then dried in an electric oven at 100 °C. After 10 h, the dried samples were placed in a muffle furnace and calcined for 4 h to obtain the synthesized samples. It was then added to 0.605 mL of Pd(NO 3 ) 2 solution (with a noble metal content of 78 g / L), equal volumes were impregnated onto the mesoporous alumina support, and the impregnated sample was dried overnight at 110 °C, and then calcined in a muffle furnace at 600 °C for 2 h to obtain a supported palladium catalyst. Weigh 1g of catalyst and fill it into a 5 mm q...

specific Embodiment 3

[0018] Specific embodiment 3: Take by weighing 10 g of pseudo-boehmite, industrial grade, with a water loss rate of 15%, dissolve it in 150 mL of deionized water, add dilute nitric acid dropwise after stirring for 30 min, and adjust the pH value of the system to be 3 . Add 5 g of polyethylene glycol (industrial grade, PEG2000) to the above system, stir for 180 min, and put the sample into an electric drying oven at 100 °C for drying. After 10 h, the dried samples were transferred to a muffle furnace at a rate of 5 °C / min to 600 °C, and then roasted at a constant temperature for 4 h. Calcined for 4 h to obtain mesoporous alumina. It was then added to 0.605 mL of Pd(NO 3 ) 2 solution (with a noble metal content of 78 g / L), equal volumes were impregnated onto the mesoporous alumina support, and the impregnated sample was dried overnight at 110 °C, and then calcined in a muffle furnace at 600 °C for 2 h to obtain a supported palladium catalyst. Weigh 1g of catalyst and fill it...

PUM

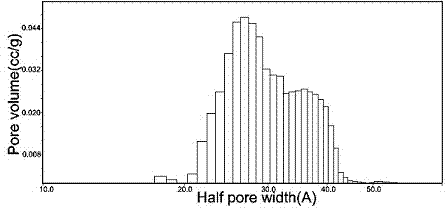

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com