Metal fiber/molecular sieve composite material and its preparation method and its application

A metal fiber and composite material technology, applied in molecular sieve catalysts, oxime preparation, chemical instruments and methods, etc., can solve the problems of easy peeling and difficult growth of molecular sieves, and achieve the effects of low operating cost, simple preparation method and controllable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

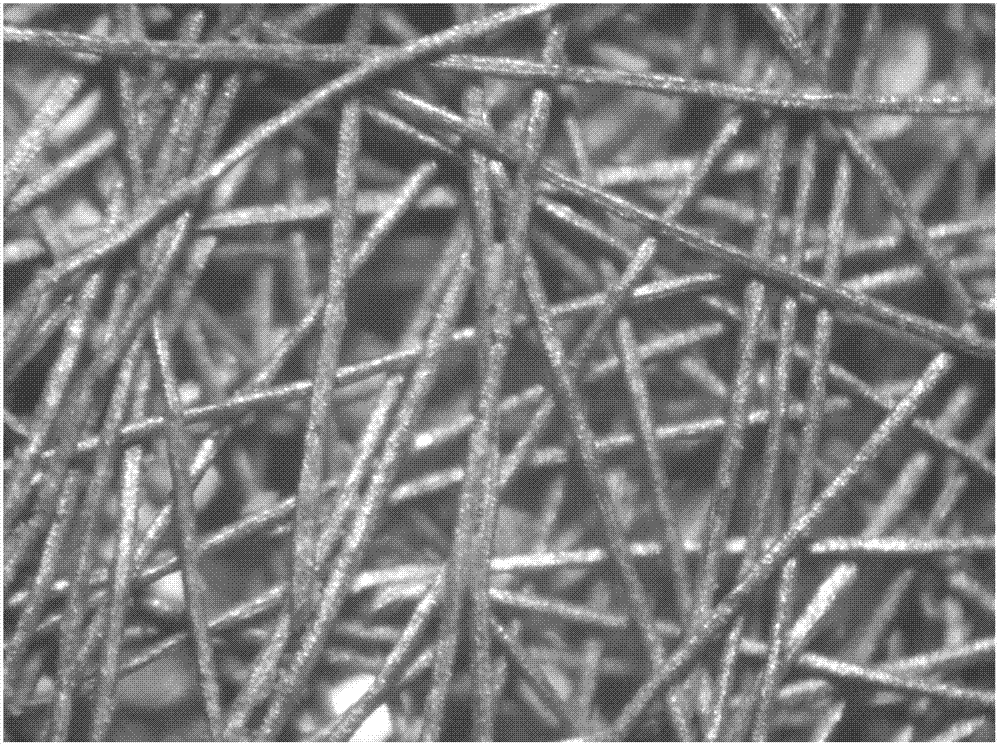

[0051] 1. Preparation of monolithic sintered metal fibers

[0052] Weigh 5 grams of nickel metal fibers with a diameter of 8 microns and a length of 2 to 5 mm, 1.7 grams of paper fibers with a length of 0.1 to 1 mm, and 1.5 liters of water, and add them to a mixer, and fully stir them into a uniformly dispersed fiber slurry; Transfer the obtained fiber slurry to the paper machine, add water to 8.5 liters, stir, drain and shape; after being dried, bake at 350°C for 1 hour in an air atmosphere; then sinter at 950°C for 1 hour in a hydrogen atmosphere, that is A monolithic sintered nickel metal fiber with a diameter of 8 microns was obtained, which was denoted as Ni-8.

[0053] 2. Preparation of monolithic sintered metal fiber matrix pre-coated with MFI molecular sieve seeds

[0054] Take by weighing 10 grams of 30% silica sol, join in the beaker that fills 290 grams of deionized water, mix; Then add 0.3 grams of MFI type silica-alumina (SiO 2 / Al 2 o 3 =180) molecular sieve ...

Embodiment 2

[0062] 1. Preparation of monolithic sintered metal fibers

[0063] As described in Example 1.

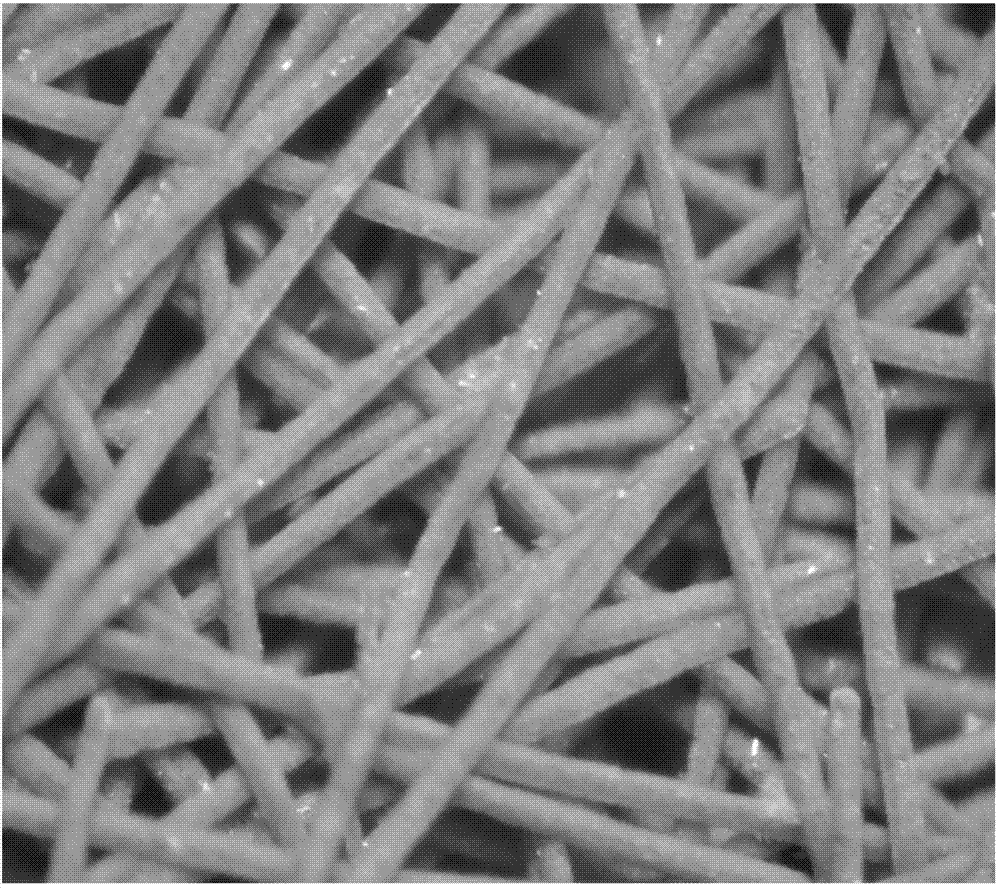

[0064] 2. Preparation of monolithic sintered metal fiber matrix pre-coated with MFI molecular sieve seeds

[0065] Take by weighing 10 grams of 30% silica sol, join in the beaker that fills 290 grams of deionized water, mix; Then add 0.3 grams of MFI type silica-alumina (SiO 2 / Al 2 o 3 =180) molecular sieve crystal seed, mixing; prepared containing MFI type molecular sieve seed crystal 0.1wt%, containing SiO 2 1wt% suspension;

[0066] The monolithic sintered metal fiber Ni-8 prepared in the previous step with a shear area of 80 square centimeters (2 grams) was used as a matrix, first placed in distilled water for 0.5 hours of ultrasonication, and then placed in a 100°C oven for drying; then it was Immerse in the prepared MFI-type molecular sieve seed crystal containing 0.1wt%, containing SiO 2 1wt% suspension, keep it for 10 seconds, take it out, dry it in the shade overni...

Embodiment 3

[0073] 1. Preparation of monolithic sintered metal fibers

[0074] As described in Example 1.

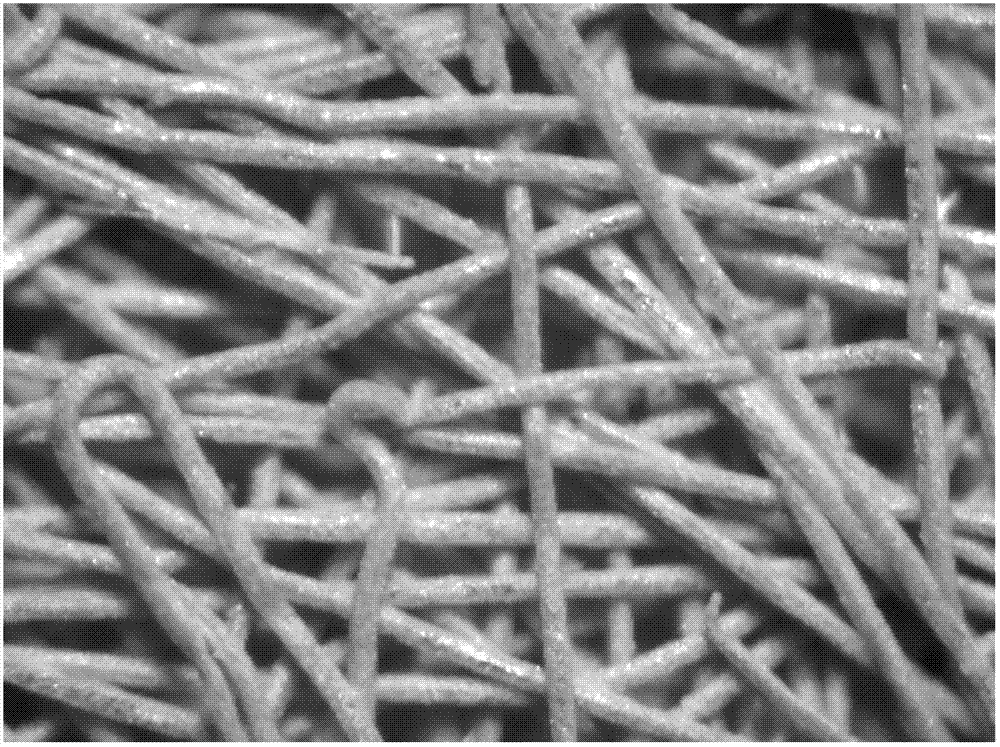

[0075] 2. Preparation of monolithic sintered metal fiber matrix pre-coated with MFI molecular sieve seeds

[0076] Take by weighing 10 grams of 30% silica sol, join in the beaker that fills 290 grams of deionized water, mix; Then add 3 grams of MFI type silica-alumina (SiO 2 / Al 2 o 3 =180) molecular sieve crystal seed, mixing; prepared containing MFI type molecular sieve seed crystal 1wt%, containing SiO 2 1wt% suspension;

[0077] The monolithic sintered metal fiber Ni-8 prepared in the previous step with a shear area of 12 cm2 (0.30 g) was used as a matrix, put into distilled water for 0.5 hours of ultrasonication, and then placed in an oven at 100 ° C for drying; then it was Submerged in the prepared MFI-type molecular sieve seeds containing 1wt%, containing SiO 2 1wt% suspension, keep it for 10 seconds, take it out, dry it in the shade overnight, put it in a muffle furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com