Tin-titanium-silicon molecular sieve, preparation method and applications thereof, and cyclic ketone oxidation method

A technology of tin-titanium-silicon molecular sieve and cyclic ketone, which is applied in molecular sieve catalyst, oxidative preparation of carboxylic acid, chemical instruments and methods, etc., can solve the problems of occupying land resources and storage space, and achieve good catalytic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Therefore, as previously mentioned, the present invention provides a kind of preparation method of tin-titanium-silicon molecular sieve of the present invention, the method comprises:

[0027] (1) Mix the unloading agent with the acid solution for beating, carry out the first heat treatment to the obtained slurry, and separate and obtain the first solid, wherein the unloading agent is the unloading agent of the reaction device using titanium silicon molecular sieve as the catalyst active component. Dispensing;

[0028] (2) The second heat treatment is performed after mixing the first solid, the tin source, the titanium source and the alkali source in the presence of an aqueous solvent.

[0029]In the present invention, the unloading agent of the reaction device using titanium-silicon molecular sieve as the catalyst active component can be the unloading agent from various devices that use titanium-silicon molecular sieve as the catalyst active component, for example, it ...

Embodiment 1

[0105] This example illustrates the methods and products provided by the invention.

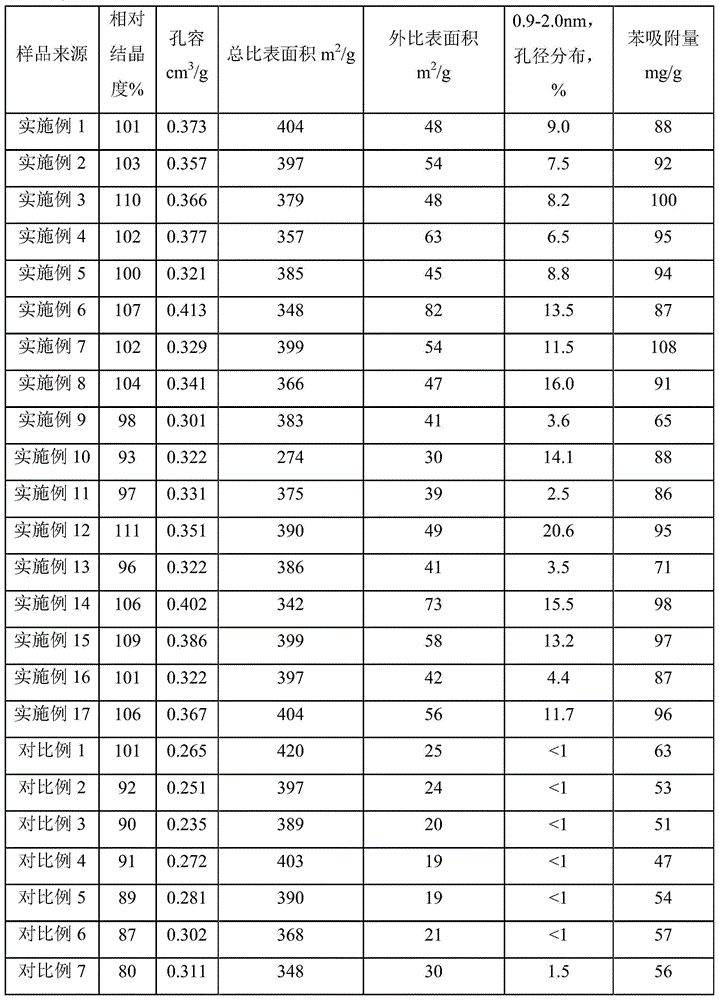

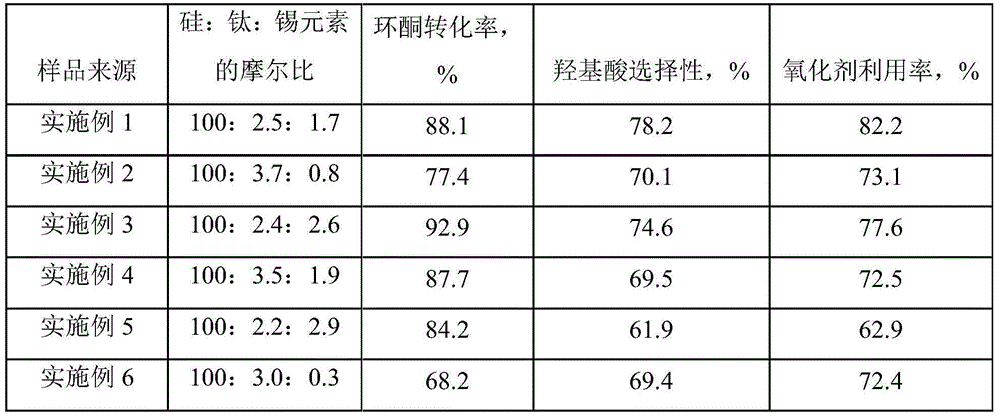

[0106] At normal temperature (20°C, the rest of the comparative examples are the same as the examples) and normal pressure (0.1MPa, the rest of the comparative examples are the same as the examples), the deactivated cyclohexanone oximation catalyst SH-2 and 1mol / L hydrochloric acid The aqueous solution was mixed and beaten, and then the mixed slurry was mixed and stirred at 80°C for 12 hours; after solid-liquid separation, the solid, tin source tin chloride pentahydrate, titanium source titanium sulfate and sodium hydroxide aqueous solution (pH 12) were mixed and mixed Put the liquid into a stainless steel sealed reaction kettle, and treat it at 170°C for 12 hours, wherein, the mass composition of the material is an inactivated cyclohexanone oximation catalyst: titanium source: tin source: acid: alkali: water = 100:1:2:10 :5:250, deactivated cyclohexanone oximation catalyst with SiO 2 In ter...

Embodiment 2

[0111] This example illustrates the methods and products provided by the invention.

[0112] At normal temperature and pressure, first mix the deactivated cyclohexanone oximation catalyst SH-3 with 5mol / L hydrochloric acid solution for beating, then mix and stir the mixed slurry at 60°C for 1 hour; after solid-liquid separation, separate the solid, Tin source tin chloride pentahydrate, titanium source tetrabutyl titanate and tetrapropyl ammonium hydroxide aqueous solution (pH 10) are mixed, and the mixture is put into a stainless steel sealed reaction kettle, and treated at 150°C for 12 hours, the mass of the material Composed of deactivated cyclohexanone oximation catalyst: titanium source: tin source: acid: alkali: water = 100: 2: 3.5: 15: 15: 200, the deactivated cyclohexanone oximation catalyst is SiO 2 In terms of acid, H + In terms of alkali in OH - count. Then the product was recovered according to the method of Example 1 to obtain a tin-titanium-silicon molecular si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com