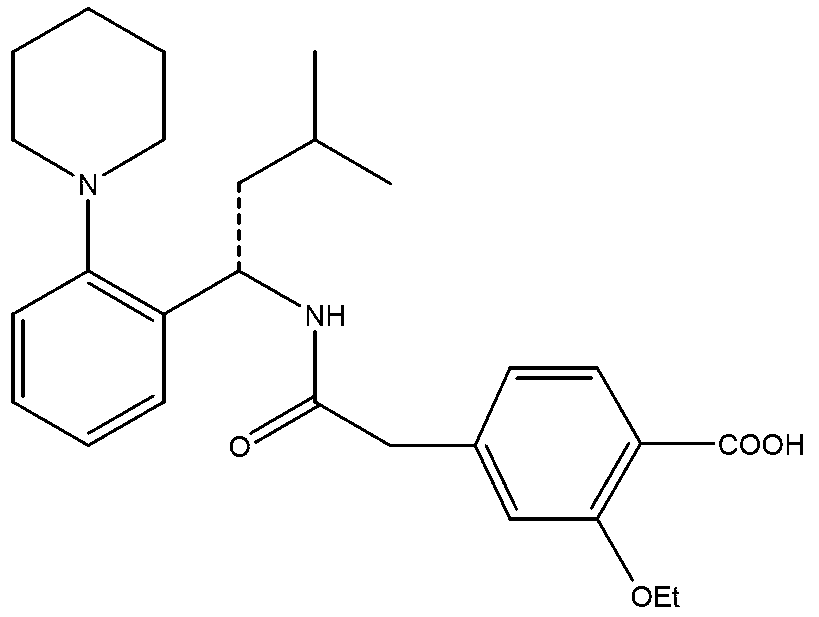

Method for preparing repaglinide intermediate

A technology of intermediates and Grignard reagents, applied in the field of preparation of repaglinide intermediates, can solve the problems of many side reactions, difficult product purification, complicated operations, etc., and achieves increased reaction safety, shortened reaction steps, and reduced side effects. product effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

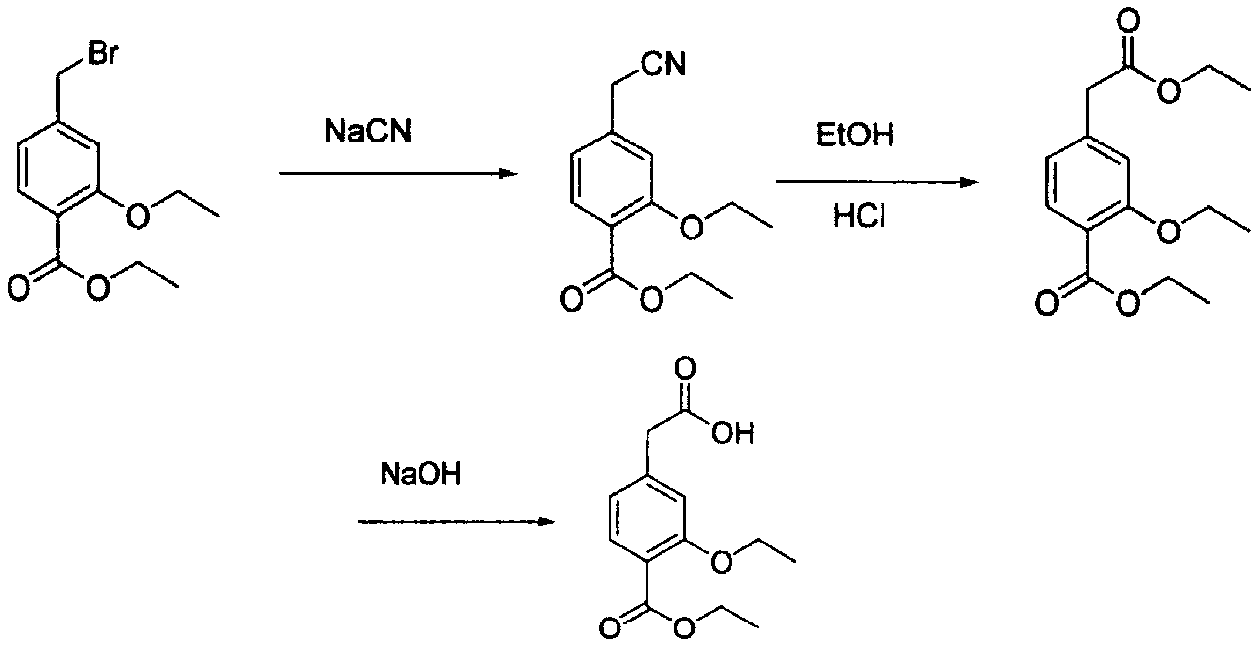

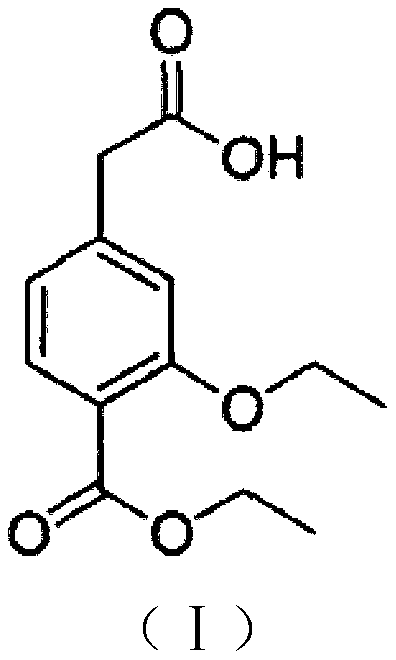

Method used

Image

Examples

Embodiment 1

[0019] Under the protection of N2, 15g of magnesium chips was added into the dry reaction flask, 30ml of THF was added to cover the magnesium chips, and the temperature was raised slowly to initiate the Grignard reaction. Another 270ml of THF was mixed with 28.6g of ethyl 4-bromomethyl-2-ethoxybenzoate, and transferred into a constant pressure dropping funnel. Add dropwise under weak reflux, and continue the reflux reaction for 1 hour after the drop is completed. After cooling down to 0°C, the solution was poured into 8.8 g of ethanol. Add 100ml of water dropwise and stir for 1 hour. Acidify with 10% hydrochloric acid to adjust the pH value of the system to 2.0. Toluene ((60m1×2) was extracted, dried over anhydrous sodium sulfate, and concentrated under reduced pressure to remove toluene. The residue was dropped into 150m1 n-hexane and stirred at room temperature overnight. Filtered and dried to obtain 16.75g of white solid with a yield of 67%.

Embodiment 2

[0021] Under the protection of N2, 15g of magnesium chips was added into the dry reaction flask, 30ml of isopropyl ether was added to cover the magnesium chips, and the temperature was raised slowly to initiate the Grignard reaction. Another 270ml of THF was mixed with 28.6g of ethyl 4-bromomethyl-2-ethoxybenzoate, and transferred into a constant pressure dropping funnel. Add dropwise under weak reflux, and continue the reflux reaction for 1 hour after the drop is completed. After cooling down to 0°C, the solution was poured into 8.8 g of ethanol. Add 100ml of water dropwise and stir for 1 hour. Acidify with 10% hydrochloric acid to adjust the pH value of the system to 2.0. Toluene ((60m1×2) was extracted, dried over anhydrous sodium sulfate, and concentrated under reduced pressure to remove toluene. The residue was dropped into 150m1 n-hexane and stirred at room temperature overnight. Filtered and dried to obtain 16.25g of white solid with a yield of 65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com