Method for preparing graphene film on nonmetallic substrate at low temperature

A graphene thin film, non-metallic technology, applied in the field of graphene thin film preparation, can solve the problems that are not suitable for optoelectronic device construction and industrial production application, difficult to realize graphene growth, increase power consumption and time cost, and achieve the preparation process Energy saving, low defect density, reduced application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A method for preparing graphene film at a low temperature on a non-metallic substrate, the non-metallic substrate being a silicon substrate, comprising the following steps:

[0047] In the first stage, first, cut the silicon substrate with a silicon dioxide film with a thickness of 300nm into small pieces of about 1cm in size, wash them with acetone and deionized water, and then put them in an oven to dry; then Use steps such as oxygen plasma cleaning and hydrogen high temperature treatment to remove residual impurities on the surface.

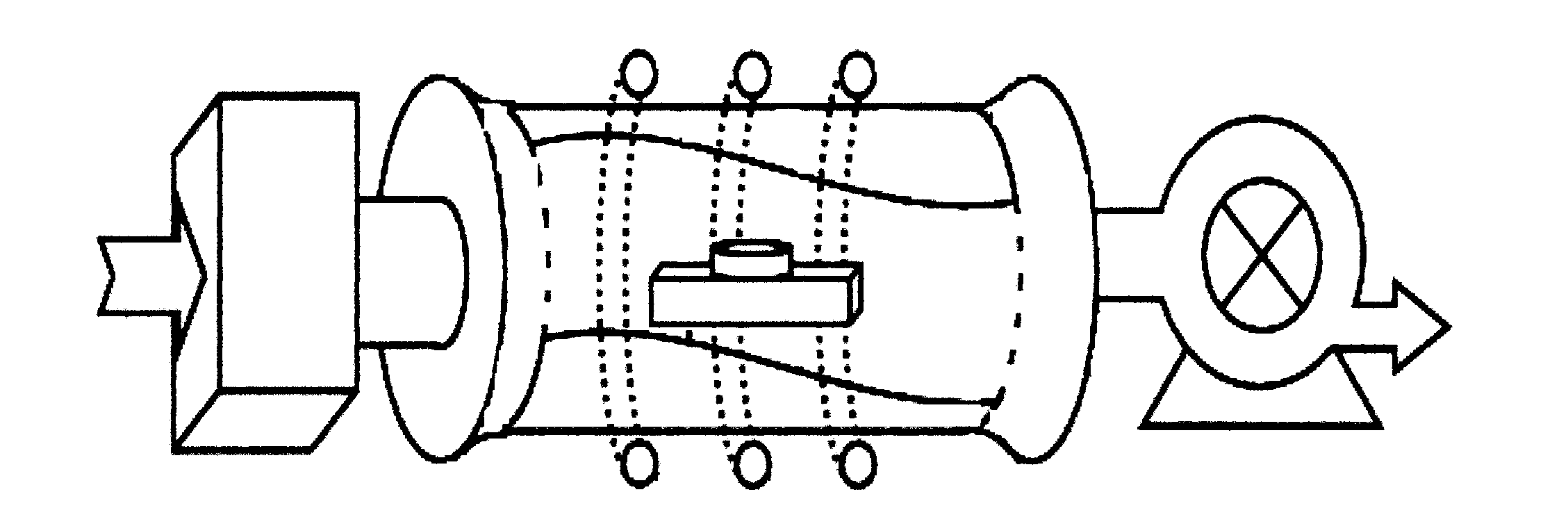

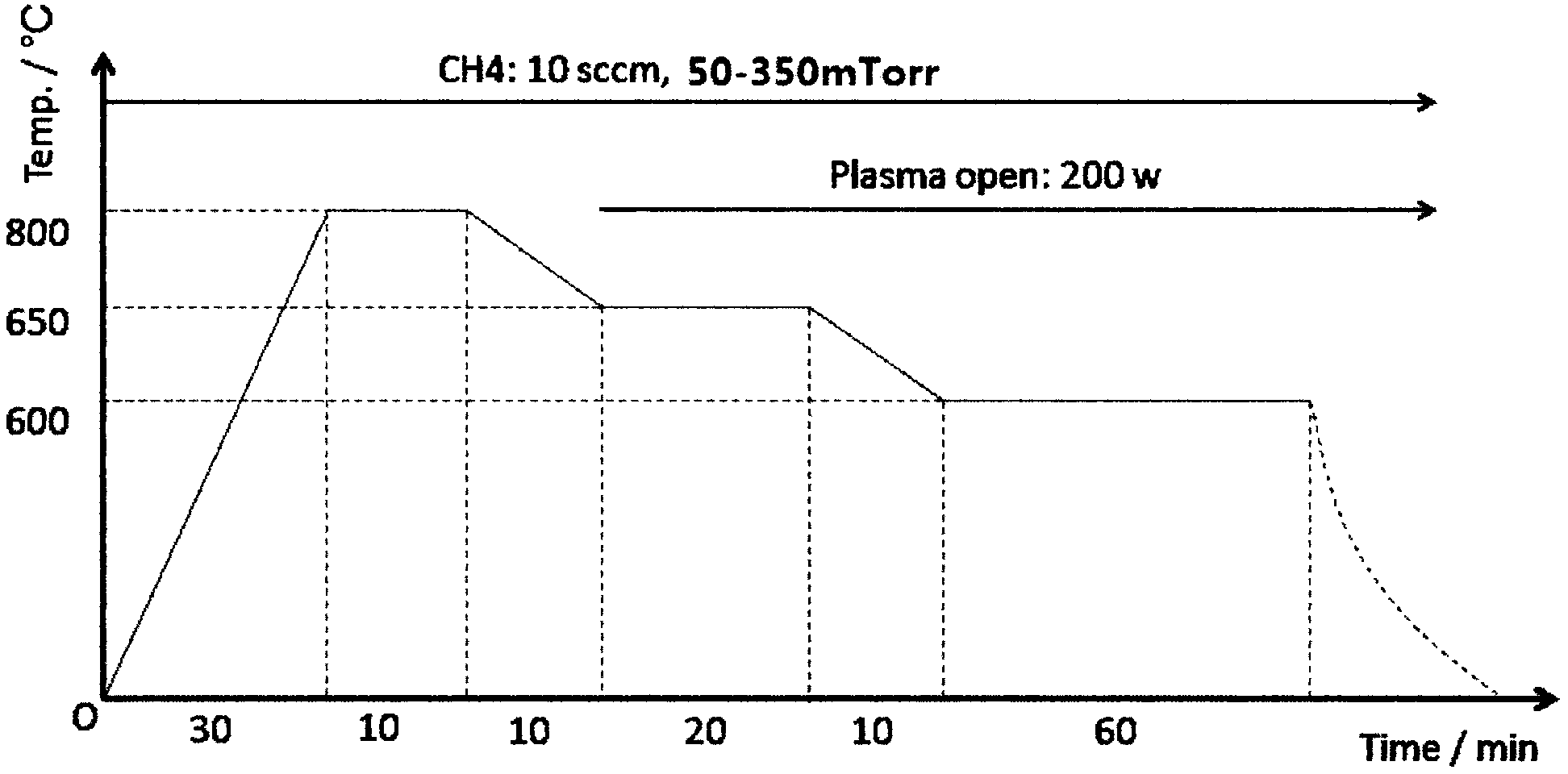

[0048] In the second stage, firstly, the processed silicon substrate is placed on the quartz glass plate, and then the quartz plate with the substrate is placed in such as figure 1 In the shown vacuum reaction furnace (the position of the quartz plate is close to the side of the plasma source, and deviates from the center of the reaction furnace by about 10cm); then, use a vacuum pump to pump the vacuum reaction furnace to a low pressur...

Embodiment 2

[0051] According to the preparation method of Example 1, the non-metallic substrate is changed to a sapphire substrate, and the substrate can be selected not to use oxygen plasma or high-temperature hydrogen for surface treatment, and the obtained graphene film is a multilayer film, and the film is relatively uniform.

Embodiment 3

[0053] According to the preparation method of Example 1, the non-metallic substrate is changed to a quartz substrate, and the substrate can be selected not to use oxygen plasma or high-temperature hydrogen for surface treatment, and the obtained graphene film is a multilayer film, and the film is relatively uniform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com